Bladeless Thurster image courtesy Texas A&M University-Corpus Christi

When Texas A&M University-Corpus Christi graduate student Daniel Valdenegro started thinking about his senior design capstone project last year, he knew he wanted to focus on making drones safer to fly. His idea? Creating a propulsion system inspired by Dyson’s bladeless fan design.

Valdenegro went to work on the project with the help of Assistant Professor of Electrical Engineering Luis Rodolfo Garcia Carrillo. From the start, the main goal was to reduce the hazards associated with the exposed propellers found on many unmanned aircraft systems (UAS), he said.

Developing a bladeless drone comes with a variety of challenges, Garcia Carrillo said, and while they’ve made progress over the last year or so, they still have a long way to go.

“In a sense, this is like a quadcopter but with a completely different propulsion system,” Garcia Carrillo said. “The blades are all internal. That makes it much more challenging to develop than a conventional quadcopter, but it also makes it much safer, which is the ultimate goal.”

Design and Initial Tests

The system works much like a Dyson bladeless fan, but is designed to create more thrust, Valdenegro said. Bladeless fan cross-section geometry, airflow properties, impellers, motors, ducted fans and conventional quadcopter dynamic modeling were all used in the propulsion system’s design. Based on their research into bladeless fan design, the team of four developed a nozzle that attaches to an Electric Ducted Fan (EDF) to create a bladeless thruster prototype.

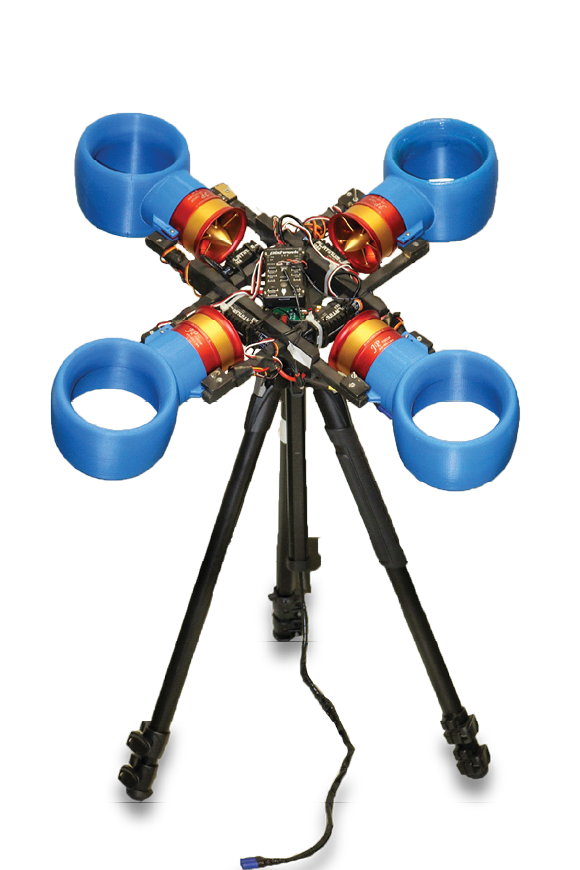

The nozzle is a circular ring with the cross section of an airfoil that’s designed to induce an airflow from its surroundings through the ring. The prototype’s four bladeless thrusters all push the forces created by the motor to control the system. The thrusters were 3-D printed and tested with the EDF.

The team has completed two tests so far: one consisting of two thrusters to determine the stability of the propulsion system in one degree of freedom, testing pitch or roll angles of a multi-rotor, and a second that included four thrusters to test stability in three degrees of freedom, which tests for pitch, roll and yaw.

“We wanted to test to see if it could be controlled in four degrees of freedom, which is how a drone moves in aerospace,” Valdenegro said. “We found out it could be controlled and we did that by creating thrusters and a platform that looks like a UAV. We put it on a tripod because we could move the tripod in all directions, like how a drone moves. We wanted to test how all those movements combined would affect the drone and if it could be controlled. We had a good result and are getting closer to it flying.”

Bladeless Drone Prototype Photo courtesy Texas A&M-Corpus Christi

Challenges

While the bladeless design does help boost safety, there are a variety of challenges that must be overcome before it can become widely used, Valdenegro said. The main challenge is the fact the rotors are all internal rather than outside the system. Instead of spinning in a vertical plane like a typical quadcopter, the thrusters all spin horizontally, creating a different dynamic.

While there’s enough power to control the vehicle and move it in different directions, the team hasn’t been able to generate enough thrust to achieve lift, Valdenegro said.

“This design is completely new,” Garcia Carrillo said. “The thrusters are installed in a different configuration so there’s no dynamic model for this vehicle as of now. One possibility is to attack the problem mathematically with differential equations to develop a dynamic model or we can make use of the data driven approach. Coming up with the proper dynamic model for controlling our system is a work in progress. It will take some time before we get a solution for this problem.”

Mexican designer Edgar Herrera’s bladeless drone concept won a Red Dot Award in 2016 image courtesy of Red Dot

Benefits

One of the main benefits of a bladeless drone of course is safety, Garcia Carrillo said. He’s been researching UAS for almost 10 years and knows if students aren’t careful, they can easily cut themselves on the sharp, exposed motors. Bladeless drones would eliminate that risk to operators as well as to the environment around them.

“This system is very easy to manipulate, even by non-expert users,” he said. “The goal is to make drones safer for everyone. Hopefully, we’ll be able to commercialize this platform.”

Garcia Carrillo also sees using the drone to actually push objects. If you tried that with a drone equipped with traditional propellers, you’d end up damaging the object or the drone, but that’s not the case with this system.

“If you want to push an object with a drone you have to add a manipulator and structure for doing the pushing, and this affects the dynamic of the system because you’re adding something external,” he said. “A bladeless propulsion system can push with its own body. This is very interesting.”

But before these benefits can be realized Valdenegro, Garcia Carrillo and the rest of the team have to get the prototype flying. While they’re always finding new challenges to overcome, they hope to make that happen by the end of the year. They’re also in the process of submitting a patent and forming an LLC.

“We’ve figured out how to control the drone at four degrees of freedom,” Valdenegro said. “Now we’re trying to maximize thrust so it can fly, and we can see how it will behave in aerospace.”