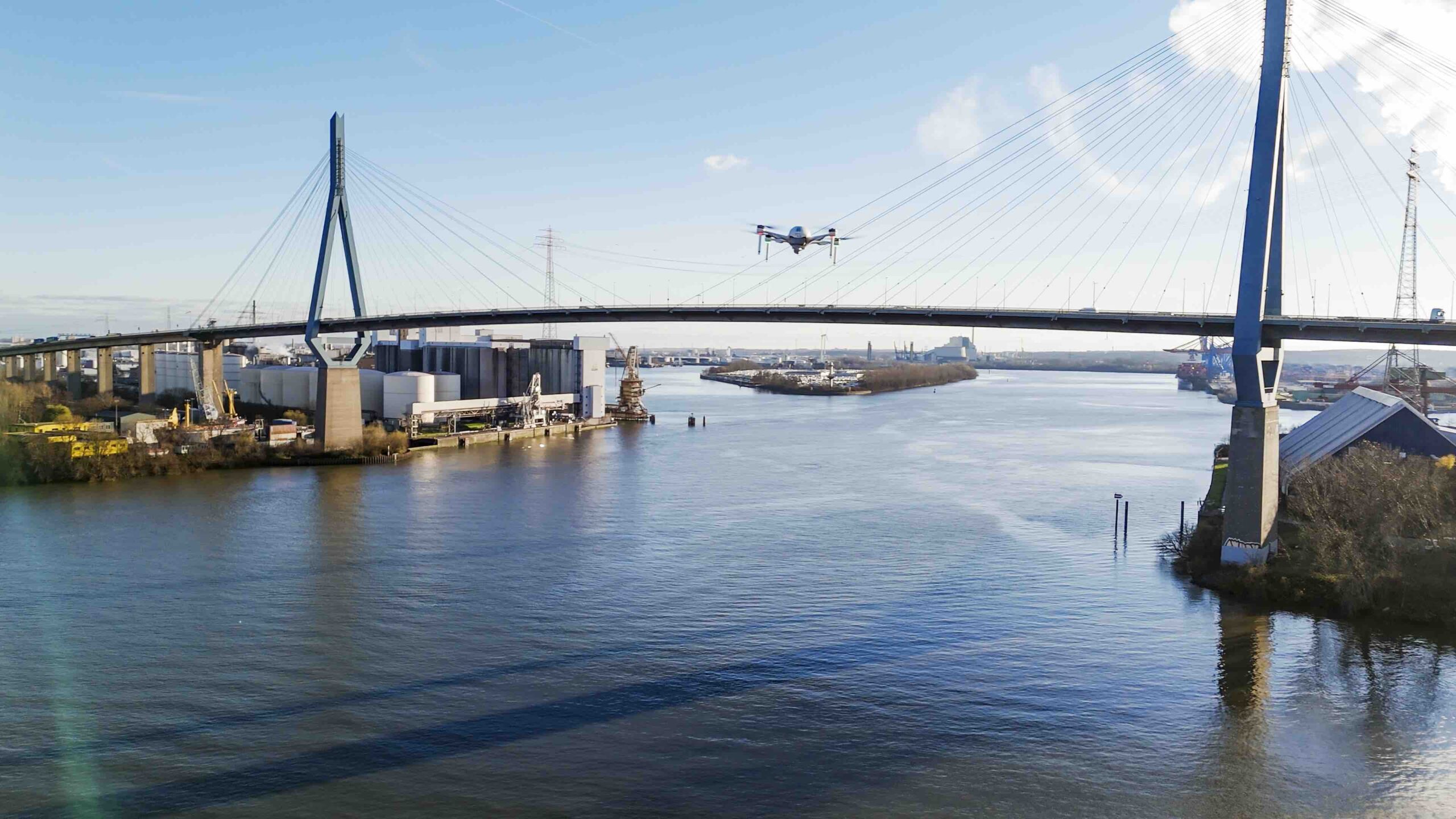

Drones are proving their worth in critical infrastructure inspections across various industries, including energy, utility and transportation. Systems, payloads and software continue to grow in sophistication—opening up even more use cases and possibilities.

In the early days, Dominion Energy focused most of its drone flights on inspecting critical infrastructure like transmission lines and substations. Since those first flights in 2014, Dominion has expanded its program to include more complex use cases in the utility sector, while also adding solar and wind farms and nuclear facilities to the inspection list.

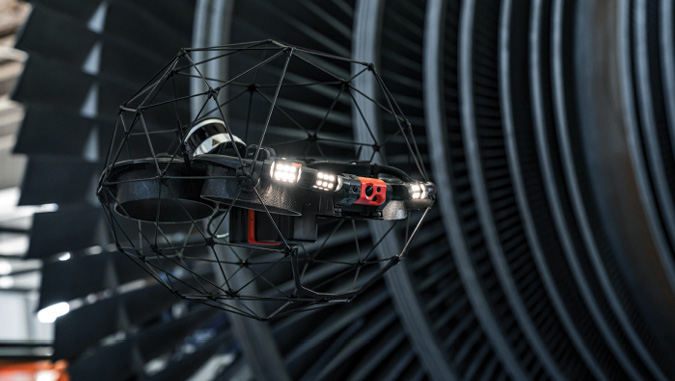

The nuclear program took off a few years ago, with Scott Paul, now the nuclear unmanned systems coordinator, leading the charge. As part of his role in work management, he oversaw day to day site maintenance. After learning about how drones were being leveraged at other facilities and within other areas of Dominion, he knew he had to invest in the technology. He spent about a year chasing down approvals and researching equipment before he finally made the first purchase, bringing in the Elios 1 and 2 indoor drones from Flyability.

Of course, he still had to prove the technology worked. The big breakthrough, Paul said, came when he was asked to fly a structure at another site that was experiencing an issue with power containment. The imagery captured allowed the team to quickly identify the cause without shutting the unit down.

“That gave them time to plan and get parts together,” Paul said. “And when they did shut down to fix the issue, the downtime was minimal because they already had the questions they needed answered. That was a big eye opener on the nuclear side of the house, and from there it just kept growing year after year.”

Drones are increasingly being deployed for critical infrastructure inspections across various industries, including transportation, oil and gas, renewables, telecommunication and power generation. As the technology improves and payloads become more specialized, a growing number of organizations are putting their trust in drones. AI advancements are making it easier to analyze the massive amount of data drones collect, speeding up defect identification so repairs can be prioritized and completed sooner.

“In energy, we’re seeing drones being used throughout the value chain,” said Sean Guerre, director of the Energy Drone & Robotics Coalition. “The use cases we used to see sporadically are now being deployed on a regular basis. We’re now beyond the proof of concept. The safety case has always been there…, now on top of that, the economic ROI is being showcased.”

EVER EVOLVING USE CASES

In the early days, drones were mostly tasked with visual inspections, flying difficult to reach and dangerous areas to collect critical data. Drones often eliminated the need for inspectors to fly in helicopters, repel down ropes or climb scaffolding, a huge boost for safety.

Drones make it possible to complete routine structure inspections with minimal disruptions, Eloise McMinn Mitchell of Flyability said, and because crews have a clear idea of what needs done before they go out to a site, repairs can be made more efficiently.

Visual drone inspections represent huge time and money savings, leaving many organizations wanting more from the technology.

“Confidence in drones is growing, so people are challenging them more,” McMinn Mitchell said, “and that challenges us to figure out the limits and how to keep pushing them.”

Today, drones are deployed to detect gas, provide detailed maps, identify heat sources, create digital twins and measure metal thickness. The use cases are becoming more complex while drones become easier to operate, creating more opportunities.

Dave Buhrman, solutions engineering manager for Skydio, has seen the “adoption curve start to spike,” partly because systems like the autonomous Skydio X10 are lowering the barrier to entry. Instead of putting engineers in a snooper truck to look under bridges for defects, for example, more Departments of Transportation (DOTs) are sending drones to quickly and safely collect data.

Cyberhawk has noticed an uptick in the number of assets customers are asking them to inspect, CEO Chris Fleming said, especially in utilities. They’re finding defects that need addressed right away, but they’re also letting clients know when repairs can wait.

“We did a proof of concept for a big utility in California that had marked 30,000 poles for replacement after traditional inspections,” Fleming said. “They asked us to do a drone inspection, and we did it in about a month. We found about 30% of the assets didn’t actually need replaced.”

Cyberhawk also identified defects missed in the traditional inspection process that required immediate repair, Fleming said. Overall, the data enabled the utility to better focus resources, saving $180 million.

BVLOS waivers are also being granted more often, opening up long linear inspections. For example, Shell recently completed a 320 mile pipeline inspection in one day, Guerre said, rather than taking on the expense and risk that comes with a winged manned flight. Chevron flew a similar mission, covering 100 miles.

Internal inspections in GPS denied environments are also becoming more common, Guerre said, with the Elios 3, for example, taking on pipe rack and tank inspections.

There’s also been a pivot to more autonomous, drone in a box solutions, American Robotics CEO Timothy Tenne said. UAS like the Optimus System can complete daily inspections, and then swap batteries and payloads to take on another mission. The same drone can be used for multiple applications, with no crew needed on site. These drones also allow for the one-to-many operations so critical for scaling.

Gas emission monitoring is a growing area in oil and gas, Fleming said, with Cyberhawk recently agreeing to fly across 26 Equinor assets to quality check efforts to lower emissions. The goal is to obtain base levels, work to reduce those levels, and then fly the assets again to prove reductions have been made.

This is just a small sample of the many ways drones are leveraged for critical infrastructure inspections. As the technology continues to advance, so too will the use cases.

MORE POWERFUL PAYLOADS

While the types of payloads used for critical infrastructure inspections is expanding, cameras remain the most popular, Fleming said. Resolution continues to improve while costs come down, enabling inspectors to quickly capture high-quality data from further away while also improving obstacle avoidance.

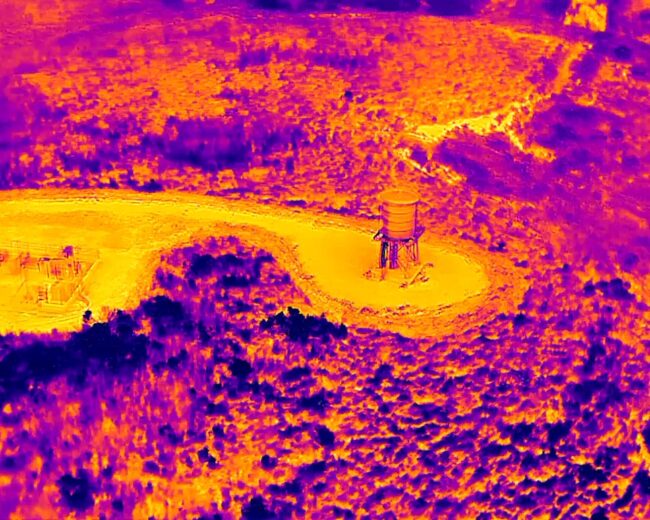

High resolution RGB cameras can show defects like corrosion in small portions of a bridge, or a misalignment in a train track, as examples, Tenne said. Drones can zoom in and out to take high quality images during the day with EO cameras and see heat signatures at night with thermal.

Thermal cameras can detect worn components that are at risk for failure, said Kelly Brodbeck, product management executive for Teledyne FLIR OEM. Many failure points “manifest themselves through heat” that can’t be seen with the naked eye or an electrooptical camera.

Most drone thermal cameras now come with radiometric capabilities to measure the temperature of each pixel in the scene—enabling more accurate measurements, Brodbeck said. It also helps distinguish between equipment that is just warm and equipment operating beyond its safety limits.

Today, drone payloads often include multiple sensor modalities, Brodbeck said, further enhancing efficiencies.

“Utilizing a dual thermal-visible payload allows for swift switching between visible and thermal images,” Brodbeck said, “as well as side-by-side viewing of both images in real-time.”

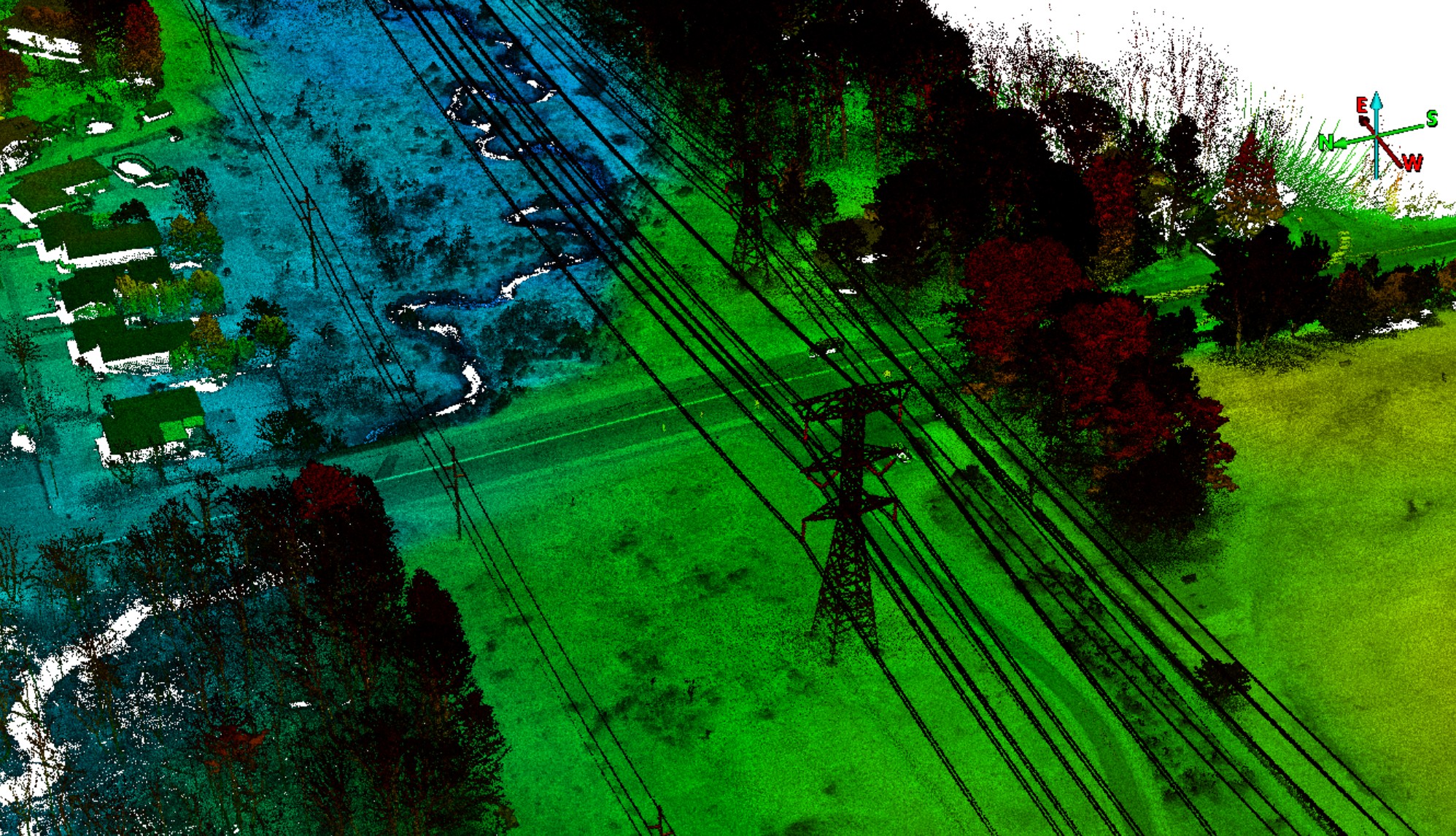

Inspectors are also deploying more LiDAR via drone, Fleming said, as these sensors are now smaller and cheaper. The point clouds generated can be used to create digital twins of the assets, measure distance between vegetations encroachment and detect changes.

The oil and gas industry is doing a lot more leak detection with drones, Vision Aerial Chief Revenue Officer Shawn Roberts said. They’re using optical gas imaging (OGI) to locate leaks and sniffers to speciate the gas or perform quantification.

“Now, you have the ability to geotag on both the optical side and the gas sensor side,” Roberts said. “If you see an issue, you can actually take a snapshot of the geolocation. On the methane side, it allows you to identify the leak, location time and date, create a report and send the report out to a scheduling system to have somebody automatically start working on a ticket to repair it.”

With OGI, engineers see short chain carbon gases on a live black and white image in about 10 seconds, said Karson Kall, director of sales engineering for WISPR Systems. They can then take the video recording and quantify the release recorded in kilograms per hour.

“Some of the testing has been pretty accurate,” he said. “We’re seeing a lot of folks looking at data and saying, ‘what else can I do with this, what can I extrapolate from it,’ and that’s driving the inspection industry forward.”

The Elios 3 carries a UT payload, McMinn Mitchell said, making it possible to check the thickness of metal assets like steel structures or pipes that are difficult to access.

“When the Elios takes a UT measurement, it geotags the location on a 3D LiDAR scan, so you can see where each measurement was made,” she said. “That makes it easier when planning maintenance to know exactly where it’s needed.”

Completing a UT inspection on, say, a 40 foot wall would take a day using traditional methods, Paul said, and that doesn’t include the time it takes to write up findings and double check measurements.

“We did a whole 40 foot wall in 30 minutes,” Paul said, “and the engineers could see the thicknesses right off the screen while we were doing it.”

Linebird’s “flying hot stick,” developed for the utility industry, is another example of a specialized payload. Line workers use hot sticks to test energized lines. Instead of a helicopter with a crew of two operators flying closely to a high voltage powerline to complete testing with these sticks, a drone can take the same measurements with no risk to humans, said Lone Star Drone owner Drew Smith, who has deployed this payload for clients.

The non-conductive payload can be fitted to any heavy lift drone, Linebird Vice President Alvin “Lee” Corbin said. The tool checks for resistance that would generate heat, providing quantitative data (unlike infrared, which is more qualitative). Line workers can identify areas where heat has caused metal to expand, schedule necessary repairs and trend what needs replaced when.

Data is broadcast down to a handheld unit on the ground in near real time, Corbin said, so line workers know immediately if emergency repairs are needed.

“It used to be people weren’t thinking about using drones for advanced testing,” said Smith, who also flies Teledyne FLIR’s cybersecure SIRAS drone. “What you’re seeing now is the industry moving toward creating bespoke technology for drones. Linebird has developed an entire system that attaches to a drone, enabling you to do a host of testing that couldn’t be done [with drones] three or four years ago. With optical gas imaging, you can see a plethora of chemicals in the air. You weren’t able to do that two years ago.”

AI DRIVING ADVANCEMENTS

AI is playing a larger role in drone applications, making it possible to accurately identify issues from the images captured during an inspection, Brodbeck said.

In the beginning, someone had to “drudge through a mountain of data,” to find what they were looking for, Smith said. Now, AI trained models make that process easier, picking out objects like isolators or insulators and analyzing them for faults.

The ability for AI to point out and quantify defects is a “huge change,” gNext President Russ Ellis said. Inspectors can spend more time evaluating the results as opposed to discovering and annotating them individually.

“AI gives us the ability to have consistent results,” Ellis said. “A crack is a crack is a crack. That gives us a huge increase in the accuracy of reporting.”

One gNext customer saved 90% on inspection and report delivery time for a complex hydroelectric dam inspection, Ellis said. That first inspection set the foundation, enabling predictive maintenance and analysis of how the asset will behave over time.

“They can see the trajectory,” Ellis said. “They now have insight into when maintenance will be performed and what type of maintenance. They have better clarity on how budget dollars can be allocated to maintain critical infrastructure.”

It’s important to remember, though, AI is complicated, Tenne said. The data fed into the models must be high-quality and accurate. He described it as working from an elementary school level of accuracy to grade school to high school to undergrad to post doc—but that takes time and requires the right drone, the right payload, the right software and the right engineers.

There has been a push for specialization in AI models, Tenne said. American Robotics, for example, has developed algorithms around rail inspections. He’s seen specialized models for port, highway and bridge inspections as well.

Feature extraction is another critical use, Kall said. Models have been trained to pull out power poles or find right of way encroachment, highlighting, say, a branch that needs to be removed before it takes out a powerline.

Object recognition is also improving.

“You can literally scan a massive parking lot with a thousand cars, looking for a specific make and model and find it instantly,” Roberts said. “That technology wasn’t there 18 months ago.”

AI also can help drones navigate, Kall said, allowing them to identify and avoid obstacles. And that, Roberts said, will help drive autonomy.

“Currently, AI is more about potential than reality, but this is rapidly changing,” Brodbeck said. “The ultimate AI application in the infrastructure space is AI-equipped autonomous drones flying from docking stations on a schedule. This is drone-based condition monitoring where issues can be identified in their earliest stages and without putting human inspectors at risk.”

THE PUSH FOR AUTOMATION

Automation is the goal for many, with drones completing inspections without a pilot on site. Some systems are already making that possible.

The Skydio10, for example, leverages navigation cameras to provide a full 360 degree representation of the world around the aircraft, Buhrman said, allowing it to navigate without GPS. The system can get into tight spaces, such as high voltage electrical substations, that traditional drones can’t. The UAS can find ways around obstructions—opening up the technology to people not comfortable flying a drone manually.

“Our goal is to drive that adoption curve up as high as possible,” Buhrman said. “And part of that is driving costs down. We’ve invested heavily in the idea of remote operations, where pilots can operate 20 or 30 drones at a single moment from anywhere in the world.”

More companies are starting to look toward autonomous drone in a box solutions, Tenne said, automating both the data collected and the data workflow. The data also must be produced exactly the way the company needs it, as many of these inspections are completed in heavily regulated industries.

“We need to be able to automate the data all the way to the customer,” Tenne said.

LOOKING AHEAD

In the coming years, drones will be more programmable, Brodbeck said. Inspections will be autonomous, routine and even more varied, helping companies meet regulatory requirements while reducing infrastructure failures.

Advances in AI and autonomy will fuel remote and one to many operations, Guerre said, both key to scaling.

Instead of expert pilots needed to fly drones, frontline staff will be able to, Buhrman said. Work trucks will be replaced with drone docking stations, making remote operations and one to many the norm.

The drone-in-a-box solution will also improve efficiencies, Paul said. If another site is having an issue, instead of him driving hours to perform an inspection, he can launch the drone from where he is.

“The ability to have eyes on an issue within minutes speaks volumes,” he said. “Long term, that’s the end game. The big win is to be able to put eyes or a camera on something as fast as possible so you minimize damage.”

Paul also envisions deploying drones to complete daily walk downs to record temperatures, for example, and automatically alert the team when a component is running hotter than it was the day before. Previous data would show how the component is trending and give insight into if it’s time to schedule a repair.

We’ll also see more collaboration, Guerre said, with aerial, ground and marine robots all working together to capture data more efficiently. The data collected will then be analyzed and put into the workflow, creating an even more complete picture.

AI will be used to analyze data directly on the drone, Smith said. Both drones and the payloads they fly will continue to shrink but also become more sophisticated.

Clear BVLOS regulations, which should be out this year in the form of the FAA’s Part 108, combined with autonomous flights will “change the landscape considerably,” Fleming said.

“What is happening now is automation is becoming more reliable,” he said, noting many drones, including Cyberhawk’s, are performing semi-autonomous flights today. “Autonmoy coupled with the ability to fly BVLOS will allow for more assets to be inspected and just the proliferation of drones in general. Utilities with assets in remote locations are going to task us with inspecting them on an annual basis. But you have to get BVLOS and autonomy in place to do that.”

While millions of assets will be flown each year, there simply aren’t enough inspectors to analyze all that data, Fleming said. AI and the ability to annotate that imagery will become critical. Industry players will work independently to create algorithms to identify common issues, but eventually, they’ll start licensing algorithms for others to use as well.

Drones will continue to disrupt inspections across various industries, lowering costs while improving safety and efficiency.

“We’re at the dawn of a new technology wave and the market is embracing it,” Ellis said. “There’s going to be explosive growth across infrastructure inspection.”