Inside Unmanned Systems connected with two hydrogen fuel solution providers to explore the energy efficiencies, extended flight times and improved logistics for unmanned fleets that this innovative propulsion technology provides.

According to the U.S. Department of Energy (DOE) National Clean Hydrogen Strategy and Roadmap, achieving net-zero emissions economy-wide by 2050 requires transformational advances in energy infrastructure. The report explains how clean hydrogen can serve as a key enabler of net-zero goals because of its versatility and potential to complement other clean technologies in the most energy and emissions-intensive sectors in the United States. This includes the transportation and logistics sectors, where UAS and other unmanned platforms are poised to play an increasingly central role.

Third party analysis in DOE’s Pathways to Commercial Liftoff report estimates that by 2030, the hydrogen economy could also result in 100,000 net new direct and indirect jobs from the build-out of new capital projects and clean hydrogen infrastructure. DOE’s “Hydrogen Earthshot” initiative, launched in 2021, targets reducing clean hydrogen production costs by 80%, aiming for $1 per kilogram by 2031.

In October, the DOE announced $46 million in funding to accelerate the development of hydrogen and fuel cell technologies as part of the Earthshot initiative. This funding will support projects aimed at reducing costs, improving efficiency and expanding the use of hydrogen in various sectors, from transportation to industrial applications. One of the topics to be investigated is demonstrating domestic hydrogen fuel cell powered motorcoach buses. Jennifer Granholm, U.S. Secretary of Energy, highlighted the importance of the investment, saying, “Hydrogen and fuel cell technologies offer a transformative pathway to reducing carbon emissions and combating climate change while driving clean energy jobs.”

Clean hydrogen can provide an alternative and backup to the conventional energy grid and natural gas infrastructure. Rather than only “electrons to electrons” pathways such as the electric grid to batteries, hydrogen can be stored and used where electrification may be challenging. This provides significant operational efficiency and flexibility in the types of dangerous or inaccessible environments UAS are most often deployed.

If BVLOS becomes achievable at scale beginning with updated regulation the FAA is slated to release for comment in early 2025, that will allow for expanded commercialization of emergent Advanced Air Mobility (AAM) applications for transport and supply chain optimization. Hydrogen propulsion, in this scenario, could be powering an industry that’s exponentially more capable, sustainable and efficient. While the emissions footprint is similarly clean using battery power, hydrogen doesn’t require further stressing an electric grid that is at capacity, and the operational gains enabled by hydrogen propulsion could result in an overall transport/energy/logistics ecosystem performing far more sustainably.

INTELLIGENT ENERGY

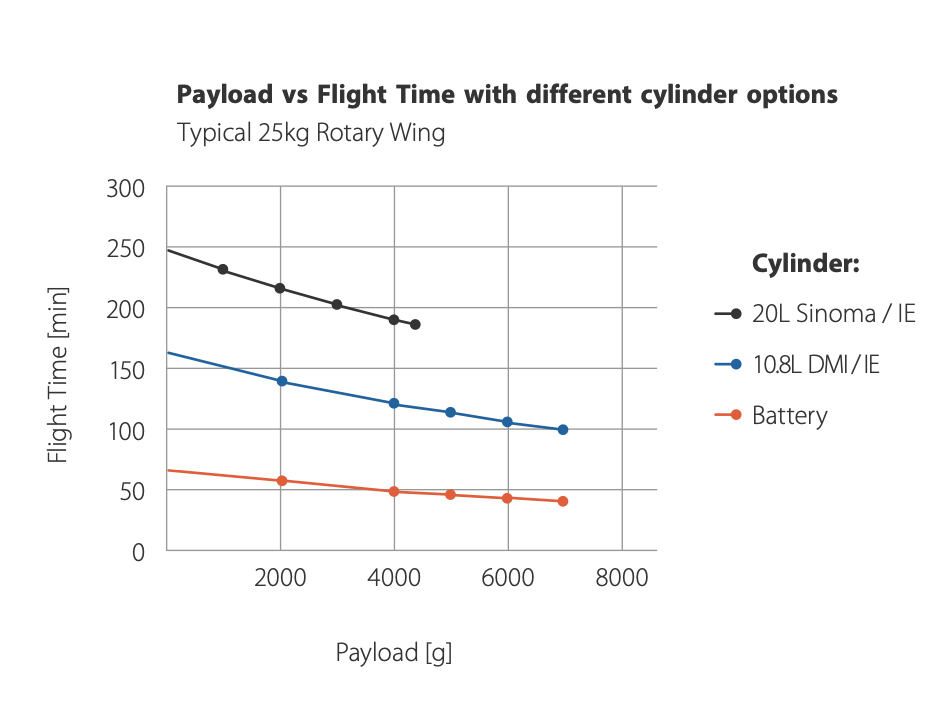

Inside Unmanned Systems spoke with Andy Kelly, product manager for Intelligent Energy’s IE-SOAR suite of UAS-specific hydrogen fuel cells. “From a sustainability perspective, hydrogen power brings significant operational efficiencies. Hydrogen fuel cells allow drones to operate longer without recharging, meaning they can be powered by green energy sources like solar or wind, if users create their own hydrogen on-site. Essentially, a fuel cell replaces the battery, allowing for extended flights, such as two to three hours compared to a battery’s 15–30 minutes.” This extension of flight times opens up applications such as offshore wind farm inspections and more efficient inspection of pipelines and power lines.

“Shell Oil is a classic case study example—inspecting a 200-mile pipeline with hydrogen drones,” Kelly explained. “They can cover it in a single day, while a battery drone would require multiple stops and battery changes. Another example is UAS inspection firm CyberHawk, who use our fuel cells for power line inspections in the UK. In military applications, companies like Zepher Flight Labs and Aurora Flight Sciences are using our fuel cells in their ISR [Intelligence, Surveillance, Reconnaissance] platforms, allowing flights lasting 7–20 hours compared to a battery’s 2 hours.”

This means fewer stops, less personnel required and covering far more ground in a single flight. At scale, in fleet operations, hydrogen’s impact grows substantially. The sustainability benefits are tied to operational efficiencies. Operators get more done with fewer resources, and for clean energy industries like wind or solar inspections, hydrogen enables them to make more substantial contributions to the overall energy ecosystem. As payloads like LiDAR become lighter, drones can handle similar tasks that used to require helicopters, without the emissions, safety risks or high operational costs associated with manned aircraft.

“We’ve worked closely with customers over the years to refine our systems,” Kelly explained. “The power levels we target—2.4 kilowatts, 1.2 kilowatts, and 800 watts—are based on common requirements in drone applications like long-distance LiDAR mapping and ISR. By keeping customer feedback central, we’ve been able to create a highly mature and reliable product line.”

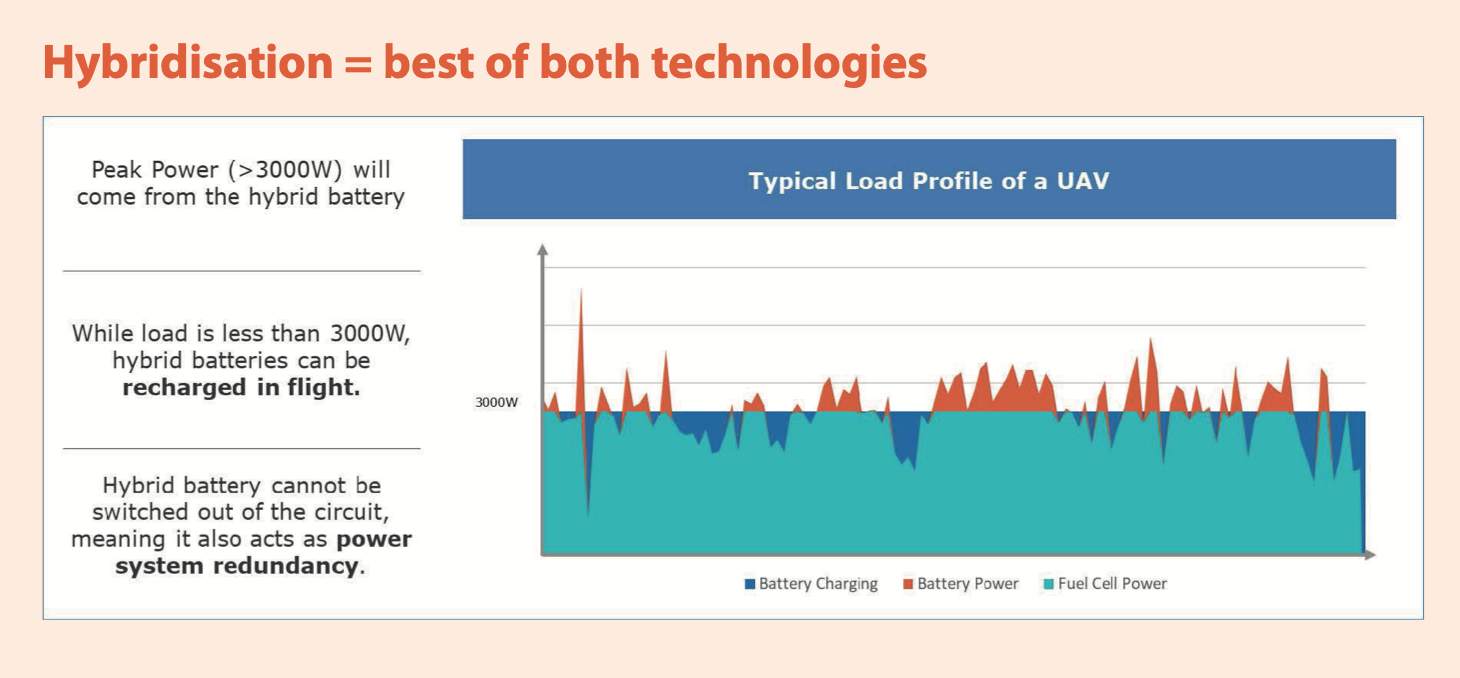

The fuel cells that Intelligent Energy produces can work in a hybrid propulsion configuration, working in tandem with other energy sources depending on the mission and payload requirements. “Our systems always include a hybrid battery, so if something goes wrong with the fuel cell, the battery backs it up. Fuel cells excel in energy density, while batteries are great for power density. By combining both, we provide a reliable power system.”

Adoption is growing, albeit slowly, partly due to regulatory factors. “We have three main customer segments: military ISR platform designers, commercial platform designers and commercial operators with existing fleets. Our focus is providing the fuel cell component to drone manufacturers, like Harris Aerial and Aurora Flight Sciences, who integrate them into their airframes. Utilities and inspection companies, like CyberHawk and Ameren, are other key clients.”

Rather than produce an airframe, Intelligent Energy focuses on the fuel cells, because “end-users often have unique needs—payload, flight duration, drone size and regional regulations vary. Rather than designing a one-size-fits-all drone, we provide fuel cell systems optimized for common power levels. This way, manufacturers can build around our fuel cell as a drop-in replacement for batteries.”

Fuel cells last significantly longer than batteries—around 1,500 hours, compared to batteries, which will lose some capacity with every cycle. Upfront, fuel cells cost about 10 times more than batteries, but they last 10 times longer, so the capex is roughly equal. Additionally, you save on operational costs, as the systems require less frequent recharging and provide more flight time per session. And with future scaling, fuel cells are expected to become even more affordable.

As regulations evolve, such as the anticipated Part 108 for BVLOS, the demand for extended, autonomous drone capabilities will grow. Hydrogen seems ideal for this shift in drone operations. “We have hundreds of units deployed in the field,” Kelly said. “These are not science projects—they’re robust, user-friendly products designed for real-world use. They function with one-button operation, just like a battery, without needing specialized fuel cell knowledge. Many still don’t realize how practical and reliable these products are.”

NOVASPARK ENERGY

“We’re excited about the opportunities in the drone industry,” said Rick Harlow, CEO of NovaSpark, a Texas-based hydrogen solutions provider. “Take, for example, some of our partnerships. Lockheed Martin, among others, works with drones that can fly up to 1,000 miles on a single fueling—using only around 200 grams of hydrogen. That’s incredible energy density, which is a major advantage.”

NovaSpark’s technology focuses on producing hydrogen from the water in the air. Their commercial-grade atmospheric water generator operates much like a home dehumidifier does. This approach provides pure water for hydrogen creation, pulled directly from the air. It provides a solution for remote or challenging environments, whether commercial or military, where transporting fuel can be difficult. “The on-site and on-demand hydrogen production can fuel drones, ultralight vehicles and even support fast-charging for battery-powered drones and EVs,” Harlow said.

Hydrogen’s advantages over batteries include faster refueling. The average tank holds about 200-400 grams of hydrogen, providing roughly one hour of flight per 100 grams, depending on fuel cell efficiency. Refueling time is minimal, about three to six minutes, which keeps drones operational longer. An example Harlow pointed to is a search and rescue mission—flying into remote mountain areas and delivering emergency supplies. With hydrogen, you get a much larger range and payload capacity, approximately 20 pounds for 1,000 miles or even heavier loads if using a runway.

“For instance, quadcopters now have multiple fuel cells and tanks per blade, providing redundancy. Safety is paramount; our tanks can handle high impacts, like from a .50-calibre bullet. Hydrogen disperses quickly, reducing explosion risks. We’re making hydrogen safer and easier to manage, especially in remote, resource-scarce locations,” Harlow explained.

“In a disaster, you’re not dependent on fossil fuels or electricity for charging, making hydrogen ideal for both commercial and defense scenarios in remote or contested areas,” NovaSpark Chief Innovation Officer Lanson Jones said.

Recently, the Air Force awarded Nova Spark a contract for hydrogen solutions in the South Pacific islands, where high humidity allows for the extraction of ample water from the air for hydrogen production. They’re also using renewables—solar, wind, even wave energy—to power the process.

Beyond drones, forklifts are adopting hydrogen, with global giants like Amazon and Walmart expanding their hydrogen-powered fleets. Other applications include hydrogen-powered tanks and trucks by companies like Hyundai and Hyzon Motors. Hydrogen offers longer ranges than battery alternatives, which is crucial for sectors like mining where fuel transport to remote locations is a significant driver of cost. With retrofit kits, combustion engines also can be adapted to run on hydrogen, allowing for a smooth transition to greener energy without retraining mechanics—hydrogen, electric and combustion hybrids can optimize for myriad weight, distance and efficiency needs.

Harlow detailed how “A hydrogen-combustible engine can also run on natural gas or propane, giving it flexibility. This approach ensures triple redundancy as infrastructure develops over the next decade. Texas, for example, has the most hydrogen pipelines due to its fertilizer industry. We’re exploring naturally stored ‘gold hydrogen’ there, as well as mixing hydrogen with natural gas, like in Hawaii, where 10% of their gas supply is hydrogen. Over the years, Texas went from 2% renewable energy to over 30%, and we anticipate similar advancements with hydrogen.”

“On the production side, major companies like Air Liquide and Air Products mass-produce hydrogen in Louisiana and Texas, then truck it out. Unfortunately, they lose some during transportation due to venting. Our solution would allow local, on-demand hydrogen production, reducing carbon emissions and lowering costs.”

Hydrogen is an attractive power source for other unmanned fleets, like driverless cars and trucks, and industrial vehicles. If electric vehicle adoption stresses an overtaxed electric grid, off-grid hydrogen charging could be a viable solution.

“Our off-grid charging units could relieve strain on the electric grid, particularly during peak hours. We’ve been in talks with cities about backup power solutions after hurricanes cause prolonged outages. Our systems can pull water from the air and generate power, making them invaluable during grid failures,” Harlow explained.

The overarching vision is for a decentralized, off-grid future. “Decentralization is key,” Jones said. “Our fuel stations don’t need to connect to the grid, so they can be deployed almost anywhere. In emergencies, FEMA could use them to generate power and even drinking water. Our systems can mineralize the water, making it safe for consumption. Our units also offer compressed air tools, so in military or remote applications, one unit can provide multiple functionalities—compressed air, drinkable water, backup power and a portable fuel source for smaller devices.”

Hydrogen doesn’t degrade, so it can remain in storage until needed, unlike batteries. Hydrogen offers a way to store and balance energy effectively, providing a large, stable energy source with redundancy options, perfect for grid backup or emergency reserves.