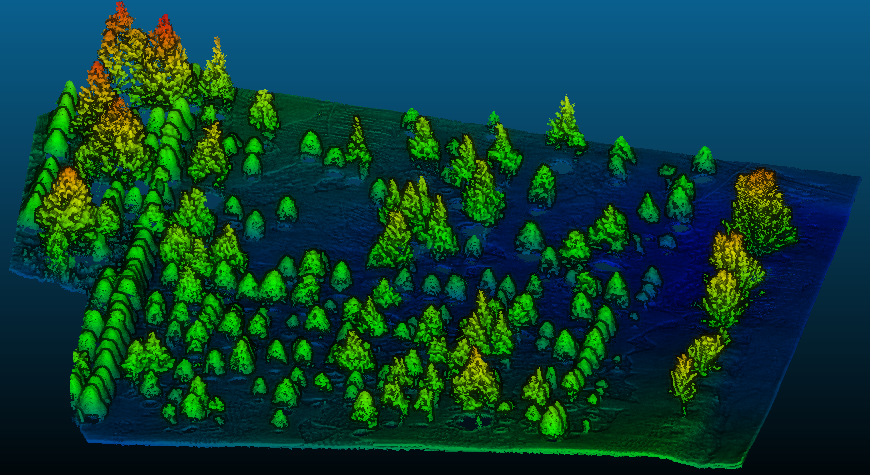

RedTail LiDAR System’s RTL-400 maps the historic Prickett’s Fort State Park, in Fairmont, West Virginia.

RedTail LiDAR Systems Verifies Tree Health for the Holidays

Between 25 and 30 million Christmas trees are sold annually in the U.S., and that’s less than 10 percent of the estimated 350 million fir, spruce, pine, cypress and cedar Yuletiders grown across the country. This time of year, trees dominate living rooms, light up the darkness of winter solstice and provide hiding places for parents filling in until Santa comes down the chimney.

But these seasonal fixtures also can be surrogates for many hydrology and vegetation problems other fields and forests encounter: crop damage; irrigation, fertilizer and erosion issues; irregular growth and infestations. Grove maturity and harvest yield also need assessment.

Consequently, RedTail LiDAR Systems of Fairmont, West Virginia, just demonstrated the value of its precision-ag UAS technology by sharing some UAS Christmas spirit with a near neighbor, the Mt. Zion Nursery. “Flying the Mt. Zion Christmas tree farm was a unique experience and a great way for us to connect to another local small business and share our technology,” said Brad DeRoos, RedTail’s president and CEO.

“In the spirit of the season, the purpose was to demonstrate the RTL-400 LiDAR system’s ability to produce very high-resolution, high density point clouds quickly and efficiently,” added Anna Rittenhouse, senior marketing specialist for RedTail. “It provided the opportunity to image a very ‘relatable’ farm experience for those who may be new to LiDAR and unfamiliar with its uses in agriculture.”

Instead of a sleigh, the company’s system was mounted on a DJI Matrice 600 so it could scan what is West Virginia’s oldest operating Christmas tree farm. At 13 miles per hour and 100 feet, the 2-acre flight lasted just four minutes. But rows of trees, terrain variation and access roads provided opportunities to produce visual imagery that might help Mt. Zion and other farmers to “zone” for higher yields and accessibility.

“It went super-fast, very efficient,” recalled Alex Rubenstein, a RedTail applications engineer who was an operator for the flight. “With a custom dovetail mount and a lock pin, it took five minutes to set up. The weather was real spotty, but we got it all done in time.” After overflying the nursery, the system took just eight minutes to process time-and cost-saving data.

High-resolution point clouds from Mt. Zion nursery’s Christmas tree farm. Photos courtesy RedTail LiDAR Systems.

Inside Santa’s LiDAR Bag

The RedTail system uses technology licensed from the U.S. Army Research Laboratory (ARL) and, weighing in at 4.7 pounds, is designed specifically for small-drone flying, whether multicopter, hybrid or fixed-wing. A microelectromechanical system (MEMS) mirror-based laser scanner moves side-to-side 400 times per second, with a laser pulse repetition rate of up to 400,000 pulses per second. Coupled with a 30-degree scan angle, two scanning modes, a 3D laser line scan and a 2D raster scan mode for “stand and stare” missions, the system offers range accuracy of 15 millimeters and range precision of 10 millimeters. All pulses are transferred to the ground to optimize point cloud resolution and density, and also provide precise focus on areas of interest and actionable data. .LAS files are exported for end users to use in the modeling/formatting software package of their choice. Data can be, well, “harvested,” for crop management decisions.

“It’s doing more than just collecting data,” Rubenstein said. “It’s got more than just one sensor; it’s a LiDAR system.” Outputs also can be used for topographic maps, boundary surveys, position information of infrastructure and maintenance schedules. Beyond precision ag, the RTL-400 can be used on construction projects, from design to documenting as-bid and as-built plans to post-construction validation. Surveying is another major application. “Power lines, pipeline corridors, grades/slopes,” Rubenstein said. “In 20 minutes to an hour, we’re covering more ground than what a ground crew does in a day.”

CEO DeRoos brought the process back to the trees. “The high-resolution 3D imagery produced by the RTL-400 provides the grower with accurate height, shape and condition of existing trees,” he summarized. “The data gathered during the flight can also help the grower know and understand where trees have been harvested, monitor the sizes and conditions of remaining trees over time, and help them plan for the future.”

Maybe next year, Rudolph will lead Santa’s team with LiDAR.