A drone approaches one of Valqari’s drone delivery stations.

Whether a delivery drone lands, lowers a winch or parachutes its cargo, these close encounters with people and property must be failsafe, theftproof and publicly palatable. A Chicago-based company believes it has solved these challenges.

Valqari is testing a secure, climate-controlled drone delivery station it claims can send, receive and store packages with any drone or delivery method. This “community mailbox” provide a secure, landing point that drones can remember—a much safer alternative to delivery drones hovering and landing in backyards or front porches, it argues.

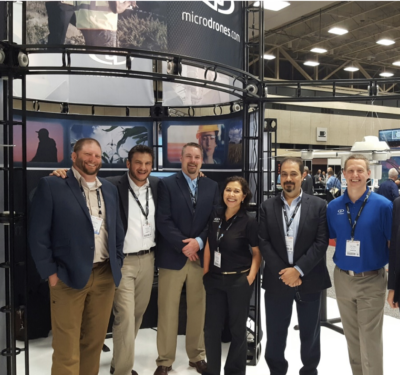

Valqari said it holds patents in 13 countries and territories throughout Europe, the U.S., Asia, Australia and Africa. Its diverse clients are testing the stations worldwide in medical, military, maritime and consumer applications. Recently, Valqari and its manufacturing partner AgEagle tested the tenets of a novel delivery system involving multiple networked stations at an Arizona golf course.

Valqari cofounder and CEO Ryan Walsh said the early tests will have far reaching implications.

“These operations will be critical in establishing best practices and standard operating procedures that will be essential in areas where the potential for risks increase, like food delivery to a neighborhood,” Walsh said. “Having learned those lessons in these early commercial operations will allow for much safer operations by the time home delivery is viable.”

Walsh thinks shore-to-ship and intra-vessel maritime applications will mature first as the FAA’s BVLOS delivery regulations evolve. “With risk of injury so much lower in maritime operations, we see it as a wide-open commercial market that is much more accessible given the current regulatory environment,” he said. Early use cases could include military or oilrig resupply operations, deliveries to remote island populations and sending paperwork to customs officers before docking.

How It Works

Valqari and AgEagle recently demoed an experimental drone delivery system at an Arizona golf course.

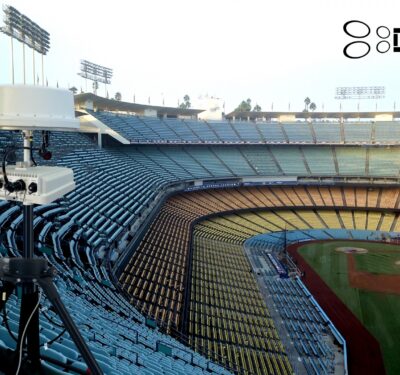

Standing 7-½ feet tall with six separate storage units, the fully automated unit functions like a community mailbox. It’s weatherproof and can accommodate packages up to 12x12x9 inches and 25 pounds. Valqari also makes a single-unit station for homes and businesses and is developing a window-based unit for high-rises.

After a drone lands or deposits its cargo on the station, an electromagnetic centering mechanism aligns the drone and/or package. A top-facing door then opens and an internal elevator lowers the package and routes it to the correct storage unit. The package remains locked there until the recipient, who operates the entire process with a proprietary app, retrieves it.

Onboard microcontrollers and a single processing unit handle secure network communications between the box, drones and users. Proprietary algorithms that manage drone dispatch and availability are offloaded to a cloud layer. Revenue-driven tasks are processed on separate, detached systems.

“It’s completely drone-agnostic,” Walsh stressed. “As long as the drone has a companion computer and capable of establishing some kind of internet connection in flight, they should have no issues running our python-based drone SDK [Software Development Kit],” he said.

During the Arizona experiment, the companies showcased a turnkey system for golf courses. Golfers ordered refreshments from a station located outside the club’s restaurant. When they were ready, a drone delivered their orders to another station on the golf course.

Matt Martin, vice president of operations for AgEagle, said engineers designed two developmental drones for the demonstration so they could test optimization strategies for key functions. “Things like landing location accuracy, package attachment and physical interfaces with the drone delivery stations,” he explained.

Both drones were equipped with three-axis accelerometers and gyros, RTK GPS positioning, LIDAR proximity sensors and an optical landing sensor. One was designed “primarily for reliability and robustness” while the other tested noise reduction. The entire test was VLOS—engineers had a telemetry link between the drones and ground stations with a handheld RC controller serving as a safety backup.

Martin said the experiment identified areas for improvement and refinement that will be incorporated into future builds of the drones and delivery stations. But its value transcended the day.

“What I personally like about what we demonstrated is that it’s scalable and portable,” he explained. “If I can safely and efficiently use a drone to deliver golf balls or beer to a golfer, then I can use that same capability to deliver time-critical pharmaceuticals from point A to point B as well. We’ll likely use this system for demonstrations to potential customers in the future.”

Photos courtesy of Valqari.