From the early days of aviation to the latest advances in hybrid engines for UAVs, Hirth Engines continues to strive for uncompromising quality.

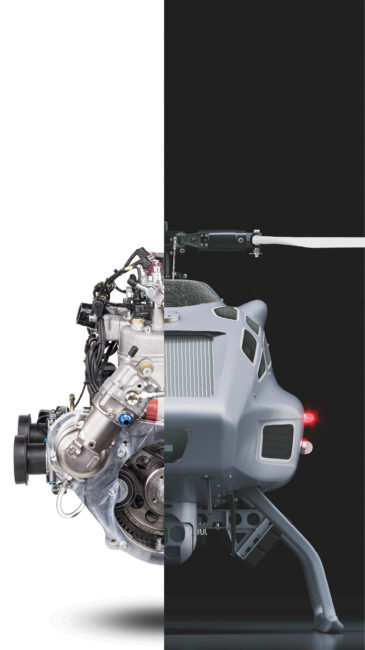

Hirth Engines GmbH has been a name synonymous with aviation innovation since 1927. Founded by aviation pioneer Helmut Hirth, the company started as an experimental workshop in Germany, quickly gaining a reputation for producing reliable, high-performance aircraft engines. Over the decades, Hirth has continually evolved, adapting to market needs and establishing itself as a leader in lightweight, efficient propulsion solutions for UAVs.

From pioneering two-stroke engines for vehicles and small aircraft in the post-war era to becoming a dominant force in the ultralight aircraft market in the 1970s, Hirth’s legacy is built on engineering prowess and an unwavering commitment to quality. Today, Hirth’s high-performance two-stroke engines power military, commercial and industrial UAVs worldwide, embodying a blend of simplicity, reliability, and state-of-the-art technology. As the aviation industry shifts toward sustainable fuels and eco-friendly technologies, Hirth remains at the forefront, leading with innovation and a focus on the future.

THE TWO-STROKE EDGE: POWER, EFFICIENCY AND VERSATILITY

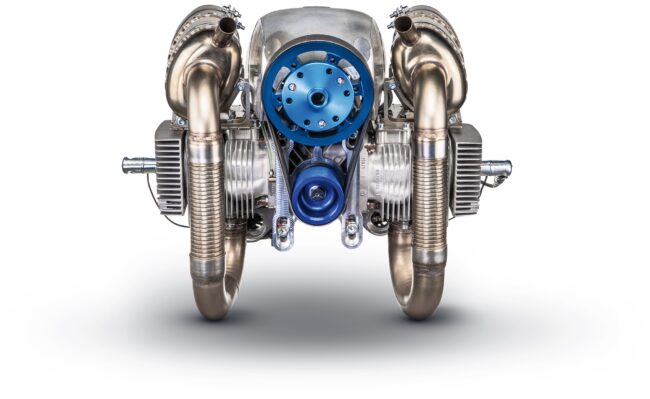

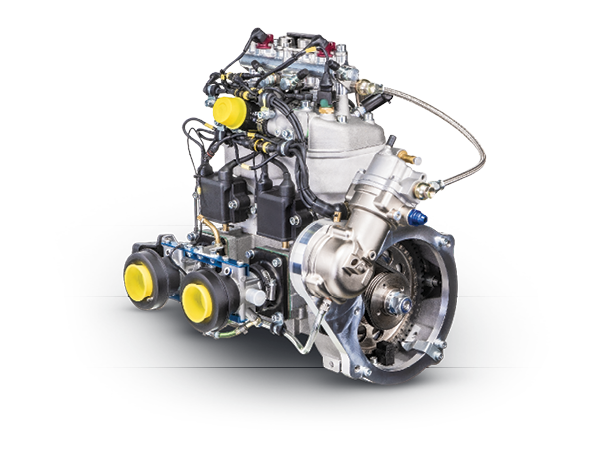

Two-stroke engines offer a competitive edge for UAVs, boasting an optimal power-to-weight ratio that translates to enhanced fuel efficiency and extended endurance. This positions UAVs equipped with Hirth engines for greater operational flexibility and performance.

Torsten Windorfer, head of research and development, explained how Hirth drives the market forward: “We optimize combustion processes using cutting-edge simulation tools, delivering more power with less fuel. We continually adapt to market demands, increasing power output while minimizing fuel consumption.”

Fuel flexibility is another powerful selling point of Hirth’s engines. “We aim to make our engines compatible with multiple fuels, including kerosene and gasoline,” Windorfer said. “By applying what we’ve learned through extensive simulations, we’re enhancing our engines’ versatility to meet diverse operational requirements.”

The durability and design simplicity of two-stroke engines is another advantage. “Our engines are designed with simplicity in mind, reducing the risk of mechanical failures common in more complex four-stroke systems,” Windorfer noted. “This simplicity allows us to extend maintenance intervals, ensuring more uptime and cost savings for our customers.”

Hirth CEO Bruno König elaborated on the company’s rigorous testing standards: “We conduct intensive 150-hour cycles to push our engines to their limits. While usage varies by application, we’ve made significant strides in prolonging engine endurance with advanced coatings and piston ring technologies. Our goal is to maximize robustness without compromising on performance.”

DRIVING INNOVATION: HYBRID PROPULSION SYSTEMS

Hirth is not just resting on its two-stroke laurels; it’s shaping the future of UAV propulsion through hybrid systems. The integration of two-stroke and electric power provides customers with operational flexibility. Peter Lietz, head of international sales and service, explained: “Hybrid propulsion enables low-emission operations at low speeds while offering the endurance of internal combustion engines for longer missions. It’s a game-changer, providing redundancy and a reliable backup in case of electric motor failure.”

König acknowledges the challenges of hybrid systems but sees the opportunities. “Balancing payload capacity with additional weight from batteries and generators is a trade-off,” he said. “However,the redundancy and operational versatility provided by a hybrid approach offer immense value to our customers. We are collaborating with partners to refine this concept, and we expect to announce a groundbreaking hybrid solution by early next year.”

Fuel efficiency and environmental impact are at the core of Hirth’s hybrid initiatives. “Combining high-efficiency engines with electric motors allows us to optimize performance and reduce emissions,” Windorfer explained. “Our ongoing trials with hydrogen fuel in collaboration with a German university aim to set new standards in clean aviation technologies.”

RIGOROUS PERFORMANCE TESTING FOR REAL-WORLD RELIABILITY

In high-stakes environments like defense and maritime operations, UAVs require peak performance and flexibility. Hirth understands this and prioritizes extensive testing to ensure reliability. Windorfer explained, “Our altitude chamber testing allows us to simulate real-world conditions, fine-tuning engine performance under varying pressure and temperature environments.”

“Our extensive track record across diverse applications, from hovercrafts to racing cars, enriches our UAV engine development,” Lietz added. “This breadth of experience provides a significant advantage to our customers, ensuring reliability in even the most challenging conditions.”

Hirth’s engines also incorporate advanced sensor and actuator technologies, setting a high benchmark for performance. “Accurate sensors and actuators are crucial for optimal combustion control and engine monitoring,” Windorfer noted. “They ensure that our engines operate at peak performance under all conditions, offering customers a reliable and efficient propulsion solution.”

PARTNERING FOR SUCCESS: COLLABORATIVE CUSTOMER RELATIONSHIPS

At the heart of Hirth’s value proposition is its commitment to building strong customer relationships. “Our goal is to go beyond just supplying an engine,” Lietz said. “We work closely with customers, allowing them to test our engines and providing expert support throughout the integration process. This collaborative approach ensures that our engines unlock their full potential within the customer’s system.”

Hirth’s global footprint, spanning markets in Australia, the U.S., Turkey, and beyond, reflects its dedication to customer success. “We build relationships by working directly with our clients, ensuring their UAVs perform optimally,” Lietz said.

QUALITY THAT STANDS THE TEST OF TIME

Hirth’s value proposition lies in its commitment to quality and reliability. “When customers have high-value payloads, they turn to us for engines that deliver consistent performance over multiple missions,” König said. “Our focus is on providing a complete, reliable system that meets their operational needs, which is an investment that pays off in the long run.”

In a competitive market where startups often offer low-cost alternatives, Hirth’s rigorous focus on quality and performance sets it apart. “We offer more than just an engine; we provide peace of mind, knowing that their equipment will be carried safely and reliably,” König concluded. “Our promise is an uncompromising standard of engineering excellence that lasts over many missions and decades.”

With a deep-seated philosophy of customer partnership and a commitment to advancing UAV propulsion technologies, Hirth Engines sets a standard for quality, reliability and innovation in the UAV market.