CEO Ricardo Mendes shares a compelling narrative of the firm’s airframes, software and Intelligence as a Service model, all of which articulate a philosophy rooted in experimentation, building mastery and creatively solving important problems with partners and customers.

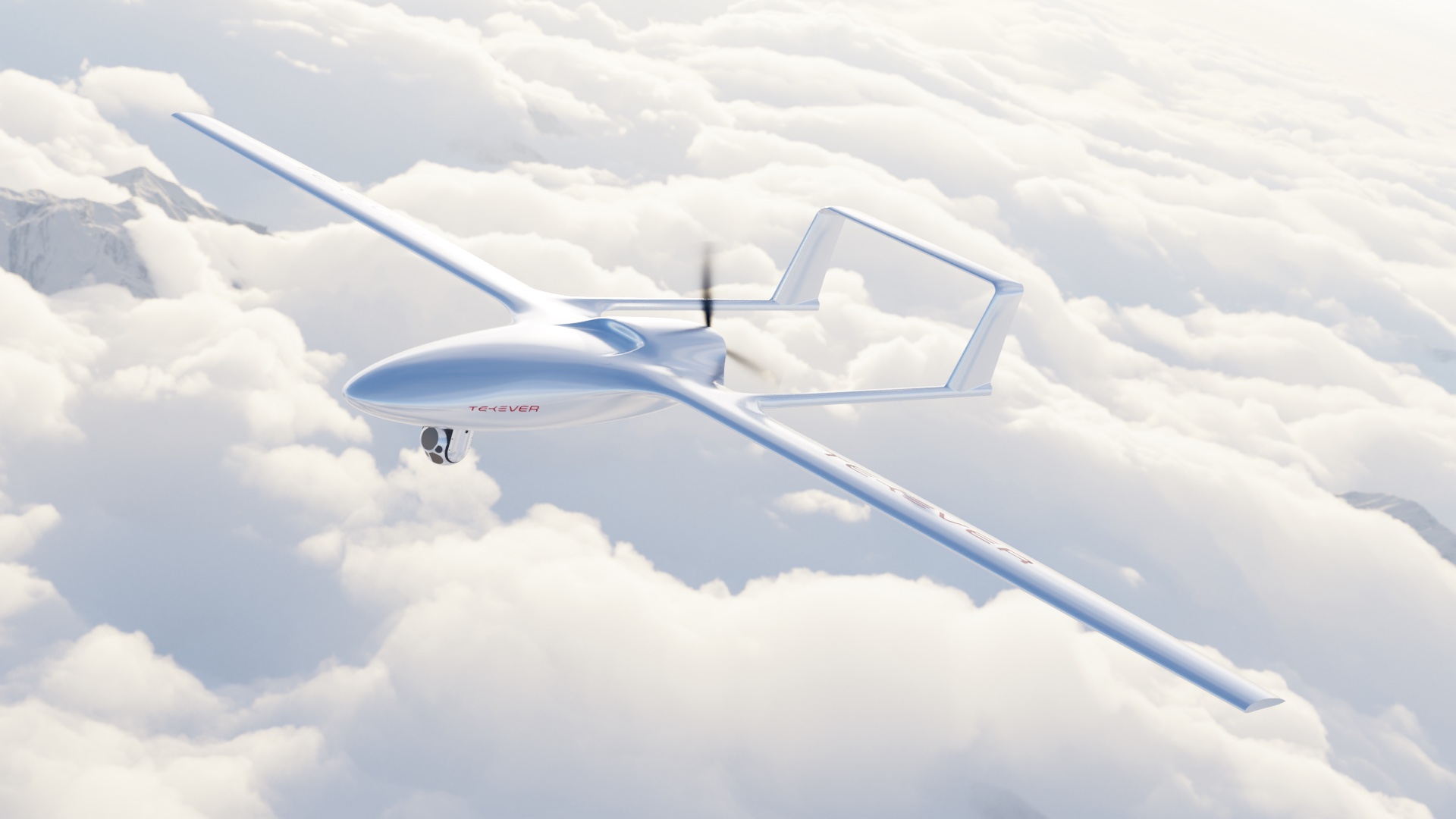

The genesis of Portugal and UK-based TEKEVER is from the world of software engineering, and the agile development framework and software as a service (SaaS) model inform everything they do. And what they do is comprehensive and ambitious. TEKEVER is vertically integrated across a UAS division manufacturing multiple airframes at different sizes and endurance levels, including the new ARX “drone with drones-as-payload” mothership concept; the ATLAS “Intelligence as a Service” data system; a Space division leveraging their radio frequency (RF) domain expertise; and a digital group providing apps and analytics.

“We actually didn’t start building airframes. We started with the software, the data, the AI and machine learning. Our background is that. We look at the platforms as computing platforms, essentially,” TEKEVER CEO, Ricardo Mendes explained. “A means to getting the computing power and the sensors to where they need to be. You have different capabilities, size, weight and power on board, which then defines what you can do. But all the platforms serve the same purpose and carry the same software and the same core electronics. It’s a data center with wings.”

The firm’s suite of UAS airframes encompasses “three products and with the ARX it will be our fourth,” he said. Currently, we have the AR4, which is a small fixed-wing electric airframe for short range missions. The AR3 is in the 25-kilo class, providing 16 to 18 hours endurance, with optional VTOL, which brings the endurance down slightly. It’s currently extremely successful in a number of both civilian and military missions. And then the AR5, which we originally designed for wide-area maritime surveillance and then today is being used in a lot of land missions as well. It was designed specifically to be able to carry maritime radars, high throughput SATCOM and so forth.”

THE ARX MOTHERSHIP

“We just launched the ARX,” Mendes said. “It will be our largest platform, sharing the same systems on-board in terms of electronics and software that the others carry, but with the ability to carry drones as well instead of just networking and swarming.”

Elaborating on the problem the ARX solves, Mendes explained, “Currently, something we do very often is have an AR5 or a few AR5s with SATCOM connections of four megabits each providing networking for smaller drones. You might be in a GNSS-denied environment, or you might be in a comms denied environment with everything jammed. You’re taking all your network and you’re doing all the coordination from above, including location and so forth. This is something we’ve done for a long time, it’s where things were born for us. This allows you to project drones like the AR5 or AR3, because they have a lot of endurance, they can travel very far and then they’re not limited by comms because you have SATCOM. You can be several hundred kilometers away. But you couldn’t do that with smaller drones. You always need to have a way to launch them and retrieve them near where the operation is happening, which could be very far away.”

The need was “first of all, to go further away and carry bigger sensors. But also, to be able to carry sensors that are detachable. To have multiple vantage points from cameras for example, or even have other sensors that require more proximity, like sonic sensors or vibration sensors, which, if you’re using a much larger platform that is much more efficient in high altitudes, you lose a lot” of fidelity. “The idea was really to be able to create something that paired the advantages of a larger system with those of a smaller system” at the same time.

Emphasizing the continuity of the UAS design and technology, Mendes said, “Most of the tech for ARX was already done, except for the physical part of carrying and releasing payload and so forth. The rest is scaling up the capabilities of AR5 and AR3. You have more energy, more mass, more room in general, and so more volume that drives your capability up. You can bring more powerful sensors, you have more compute power, you have more storage, you have more redundancy for data links, for example. But in essence, it’s the same concepts that we’re already doing on AR3, AR5 and now ARX.”

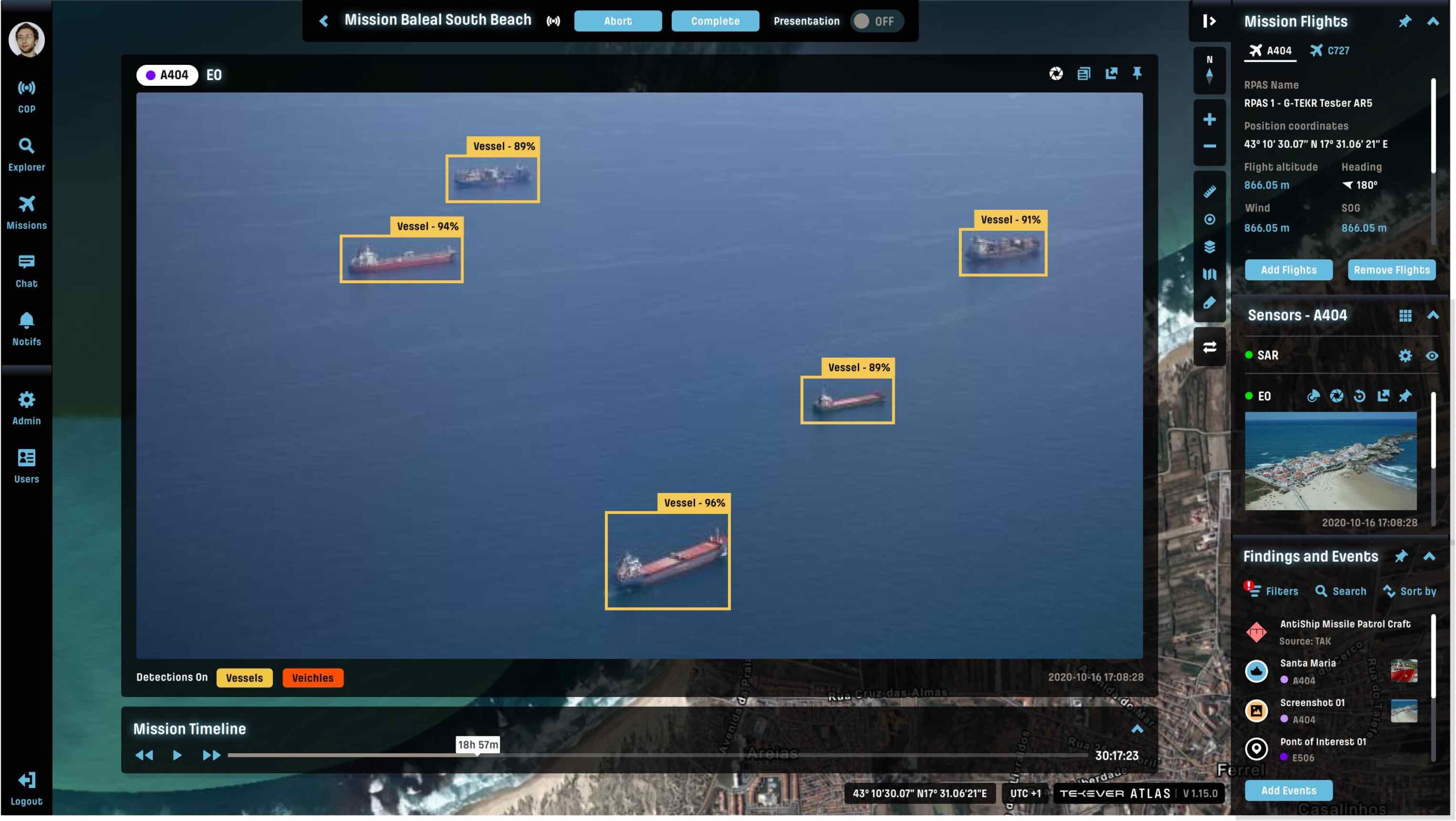

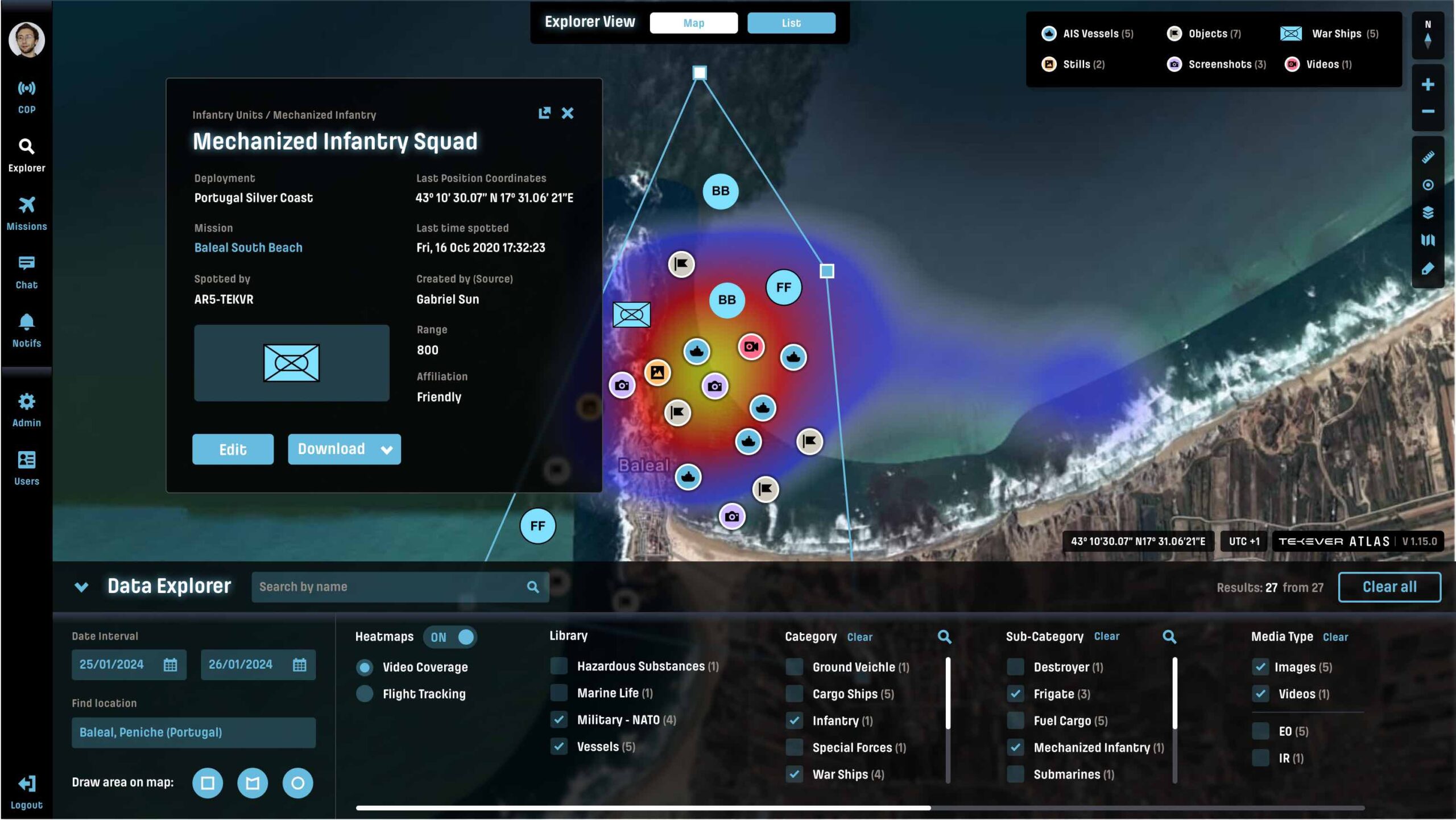

ATLAS: BUILDING INTELLIGENCE AS A SERVICE

Speaking about how the ATLAS Intelligence as a Service AI/ML data system is provisioned, Mendes explained, “When we started looking into this market, UAS in general and ISR in particular, we decided to go into ISR because we thought it’s essentially data and then an intelligence and knowledge problem. That’s not an aeronautical problem at all. As software engineers and experts in these types of technologies, we came into this market because we understood that it wasn’t about the planes, it wasn’t about the platforms, it was about the data. And data is what software engineering is about, and what AI is about.”

In terms of technical facilitation of the Intelligence as a Service model, TEKEVER employs a three-part framework. Edge computing—processing data at the source on computers embedded within the airframes—sits at the front of the framework, followed on by ground station local machines for further analysis and then cloud-based big data processing power and analytics. The resulting intelligence and insights are then presented to customers via the software interface of ATLAS.

Mendes explained, “You need to think in terms of what today is called edge computing and the filtering of data from as close as possible to that edge. Ideally, you would be glued to the lens if it’s a camera. Then, you work backward, because the more backward you go [from airframe to ground station to cloud], the more capability you have in terms of compute. So, that’s the first step, it’s [gathering data] from the plane, as close as possible to the sensors.”

How this functionally operates on the TEKEVER airframes is often through custom designed and manufactured components that possess data processing capabilities. Mendes continued, “There are multiple layers for each of our planes. For example, we manufacture our own gimbals, we manufacture some of the sensors, precisely because you have storage and computing inside the gimbal. We do a lot of the computing on the plane, not just streaming it to a ground station” for processing on another computing platform.

The second stage in the framework is to further mine and refine the airframe-captured data. Mendes said, “the second part then is you get all the data back to the ground station.” The data coming through from the on-board sensors and processing “needs to be very filtered because you’re coming through data pipes. Our systems typically have five, six or seven different data links on board. You manage those, you maximize throughput, you compress and encrypt. But essentially you get data in real time to process [from the airframe] and then you’re on the ground and you can do a lot more.”

After processing via the ground station’s on-premise computers and servers, the next step in provisioning Intelligence as a Service is porting the data to the cloud. Cloud computing is “where you deal with much bigger data sets and where you can have a lot more freedom. This is how we always look at things when we deploy. Our goal when we go into a use case is always from this point of view.”

The selection of which of TEKEVER’s suite of airframes to deploy for a particular use case is “a detail within this [methodology],” Mendes said. “It drives costs in different ways because it’s different types of platforms with different capabilities and requirements, but it’s a function of this approach. It’s not the other way around. When we look at a problem, we look at it from this perspective and the business model we can bring to the customer is also aligned with this.”

DELIVERING INTELLIGENCE

Mendes expanded on the service model for delivering its data solutions to clients. “The traditional business model you have in the defense market, for example, is you sell everything. But coming from a software area, we lived through the ‘as a service’ shift beginning with Salesforce.com” providing, in that case, customer relationship management (CRM) software on a subscription model. “And in this model, you don’t buy software, you rent software. You subscribe to it. So why should [UAV-based data solutions] be any different? It’s like adopting Salesforce. Everything is folded into a monthly fee. It’s a simple to acquire, simple to grow, simple to maintain and simple to evolve solution. That’s where we come from, and we have several customers that work like this.”

However, TEKEVER also supports customers who gain value from the UAS-based data solutions but adhere to a more traditional business model of purchasing rather than subscribing. “We have several customers that say, ‘I want exactly that capability, but I want the traditional business model,’” Mendes said. “Typically, military customers or customers that want to retain ownership of the different parts. The data always belongs to the customer. But there’s a number of business models in-between the extreme of you do everything as a service and the other extreme where the customer owns everything,” including airframes and their maintenance.

Regarding data security, particularly as it relates to data coming out of active warzones, Mendes said, “For example, in Ukraine, it’s public knowledge that we have a number of platforms there that are being used very successfully. One of the things that’s less known is ATLAS is a fundamental part of all that and we can’t have access to live data from where the missions are happening. We manage it, but we don’t have access to it, by design.”

CUSTOMER COLLABORATION AND CO-CREATION

Describing how TEKEVER develops its end-to-end solutions for a new use case or vertical, Mendes explained, “It all depends on the specific mission, on the specific type of data. And the entire chain, the entire solution, end-to-end from the sensor to the cloud. It needs to be thought of for each use case. That’s what you do when you enter a new vertical. When you start working in maritime, or oil and gas, or environmental, for example.” When entering new industries with unique use cases, Mendes explained, “What you do is basically configure this entire chain to that particular use case. The framework is the same, the base stack is the same. Sensors might differ, compute power might differ, the planes might be different, but essentially, it’s the same backbone that’s adapted to a different vertical.”

TEKEVER’s customer-centric, full-service approach can evolve organically to solve for novel requirements. “At first, you might guess that it’s this sensor and that sensor, Mendes said. “But you’re guessing, you don’t really know. And then you engage more with the customer and what you need to do is iterate really fast to understand the use case. And in the beginning, you’re relying mainly on human intelligence, on your capability to understand the data. Then progressively, you need to complement that and to some extent replace that with techniques and algorithms that are trained based on the data you’ve gathered and train a model to do it for you.”

Explaining further how this collaborative iteration takes shape, Mendes said, “This process takes time and requires adaptation of the platform, of the sensors, of the algorithms, of the ways of working. The business case might be completely different, which might require you to change which platforms you’re using or even change the platforms to adapt to the envelopes or where you’re flying. For example, maritime use cases are extremely difficult because of humidity and wind” and other environmental variables.

CULTURE AS A DIFFERENTIATOR

“How important is it to evolve? It’s everything,” Mendes said. “If you’re not able to do this, you’re basically a platform provider. You’re offering an off-the-shelf capability.” Differentiating their approach and value proposition, Mendes underlined, “The way we work, the way we tackle problems, is you have an infrastructure that’s constantly evolving, use cases that are significantly big and interesting and have enough money in them, and require the type of expertise we have. And you focus on them, and you adapt until you have something that’s just spot-on. Then you continue with that thing, because then the customer will require more, and you’ll be able to do more.”

TEKEVER’s philosophy is to dynamically progress along with customer needs, creating a virtuous cycle of solutions for some of the 21st-century’s most pressing challenges.