Drones are becoming a common inspection tool across various industries, enhancing efficiencies, providing more accurate data and improving safety.

Just a few years ago, drones were viewed as a novel inspection tool, with the systems typically only deployed for very specific missions to collect very specific data. As these platforms have proven their value, there’s been a shift: Drones have become integral to routine inspection plans across a variety of industries, including oil and gas, utilities and construction, and their involvement is only expected to grow.

UAS are becoming part of a structured way to collect data, whether through in-house programs or third parties, providing insights that go beyond this asset has a leak here or corrosion there. Decision-makers can look back on the maps and models created for a more wholistic view of their assets and sites. And the data collected is going higher up the management chain for decision making and is now being disseminated across groups. Images from one mission can be analyzed for various purposes, offering even more benefit for the companies deploying this technology.

Digital twins are also becoming more common, with the images collected during a drone flight used to recreate assets and even entire plants. Engineers and others can use these 3D models to complete inspections, store information, monitor change, schedule maintenance and predict when it might be time to retire an asset—and they can do it all without ever having to step foot inside a plant or on a construction site.

Then there are the payloads. Sensors are becoming even more sophisticated, with smaller payloads that can collect high-resolution imagery becoming the norm. Beyond RGB cameras, inspectors are routinely flying thermal and LiDAR sensors. And specialized sensors, such as optical gas imaging, to check for leaks and ultrasonics to measure metal thickness, are becoming more readily available.

As professionals increasingly rely on drones to safely complete inspections, manufacturers are responding to the need to make them easier to fly, enabling more companies to take advantage of the technology. Automation is of course the ultimate goal, opening up even more possibilities once achieved.

Drones are making inspections both more efficient and safer, eliminating the need for inspectors to erect scaffolding to climb assets, crawl into confined spaces to take measurements or to fly a helicopter to look for defects. Assets can be inspected more often, meaning analomies are spotted and fixed sooner, saving companies money and time while also enhancing worker safety.

“There used to be more pushback, but now we have so much data and evidence showing the value in terms of safety and the reduced downtime for assets, the argument is making itself,” Flyability Senior Communications Manager Zacc Dukowitz said. “Global companies that may have only had a few drones a few years ago are now adopting huge fleets and rolling out drone programs at scale.”

PREPARING SITES, TRACKING PROGRESS

Surveying and mapping sites via drone is critical, with the information often used for inspection purposes down the road. Traditional methods typically require crews to walk sites for days, which is time consuming and dangerous, while drones can usually provide the needed information in a matter of hours.

For Amr Raafat, vice president of VDC and technology at Windover Construction, deploying drones to survey sites before construction has become standard. The maps created are used for the foundation phase, allowing the team to identify conflicts between engineering drawings and reality. With this vital quality control process, clashes can be detected and adjustments made before concrete is poured, saving clients thousands of dollars and helping them stay on schedule.

“We get a point cloud of all the pipes and where they are going,” said Raafat, who has had an in-house drone program for six years. “We can overlay that on the as-built the same day and detect any discrepancies between the pipes or find missing fixtures in real time. A plumber can go in the next day and move the pipes an inch if needed. When we pour the concrete, we are 100% positive they will be in the intended location when we start putting toilets in two months later.”

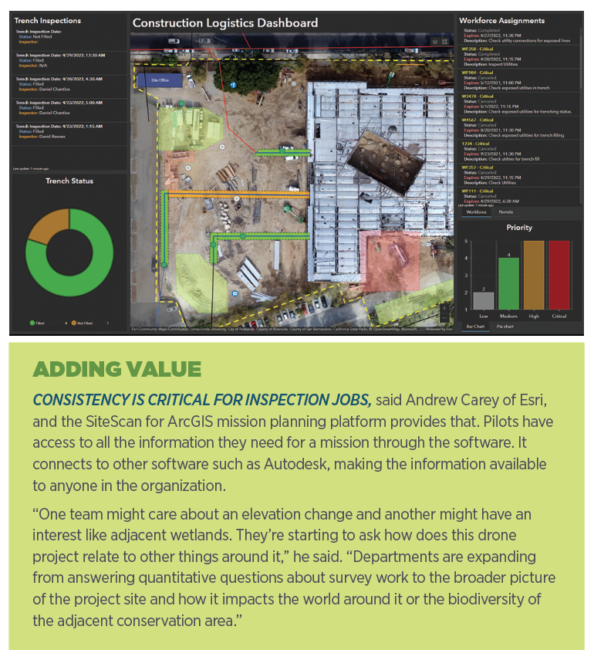

As the frequency of data collection goes up, so too does the use of change detection, said Andrew Carey, account executive, AEC, global imagery and remote sensing at Esri. Managers are flying drones weekly, even daily, so they’re able to get a better feel for how a site is changing. Feature extraction is also important, with AI and deep learning tools making it possible to remove clutter from an image.

Cut and fill analysis is critical for pre-construction work, Vision Aerial Head Integrator and Lead Pilot Chris Jackson said, as is the ability to provide accurate stockpile calculations. These measurements are easy to calculate with drone data, telling crews how much material they either need to buy or remove to level the site.

Once construction begins, crews can fly drones daily to track progress and inspect the work, Percepto cofounder and Chief Commercial Officer Ariel Avitan said. By using artificial intelligence, Percepto software can remove every aspect of a picture except the asset being inspected. And because the drone-in-a-box solution is autonomous, the images collected of an asset are the same over time, increasing accuracy.

Reports are sent out daily with the latest information, Avitan said, keeping everyone up to date and ensuring problems are noticed and addressed early in the process.

“The ability to monitor sites on a daily basis makes projects more efficient because you have a day-to-day understanding of if you’re on track,” Avitan said. “And if not you can adjust, instead of finding out six months later you’re not going to meet the deadline, which could cost millions.”

CRITICAL ASSET INSPECTION

Drones have become part of the inspection routine for many critical assets including tanks, pipelines, boilers, transmission lines, distribution stations, solar farms and wind turbines, to name a few. UAS can quickly and safely collect the data necessary to properly maintain these vital structures, enhancing safety and reducing the downtime typically needed to inspect and repair problems.

Oil and Gas

The oil and gas industry is leveraging drones for core asset management and inspection, both offshore and on, Cyberhawk Chief Commercial Officer Matt Zafuto said. Engineers can turn the data collected into insights that go beyond just performance analytics, and quickly take any necessary action, whether that means making a repair or monitoring a particular area more frequently.

“We’re now able to couple domain expertise and code that into our iHawk software, highlighting areas that need to be looked at,” Zafuto said. “That’s increased inspection efficiencies quite a bit. We know the general defects on an offshore oil platform to look for, and we’re using software solutions to identify them.”

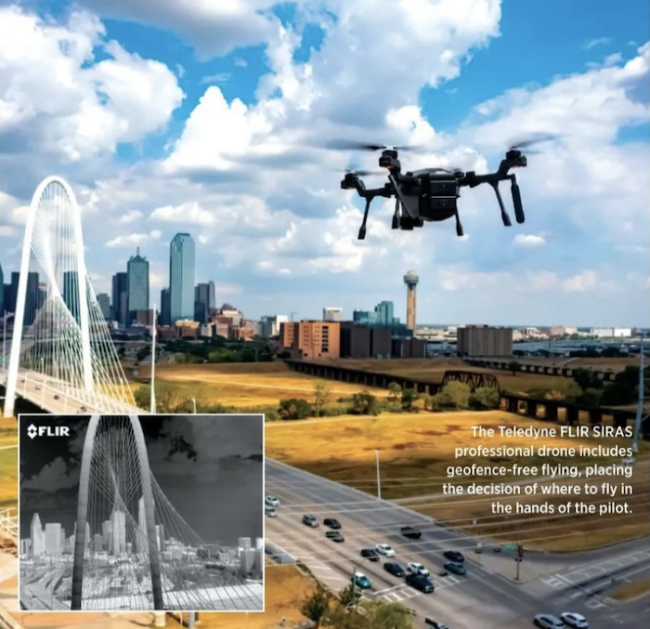

The SIRAS drone from Teledyne FLIR features both visible and thermal cameras, combining the two for more in-depth inspections, Product Management Executive Kelly Brodbeck said. Say a tank farm holds 300 tanks that need inspected regularly: SIRAS inspects the tanks, looking for defects and measuring how full they are with the thermal sensor, while the RGB camera takes a picture of the outside label that includes safety information along with tank number. MSX technology overlays the edge detail from the visible camera on the thermal image, so inspectors end up with one image with all the information they need about the asset and its condition.

Drones are also handling confined space inspections, Dukowitz said, reducing the need for rope access and other dangerous methods to get into the units. Boilers, pressure vessels, large storage tanks and FCC units are among the assets that can now be inspected remotely.

One of the challenges of using drones to inspect these assets is they’re often homogenous, Dukowitz said. It’s easy to lose track of where you are if you’re just looking at a visual feed, and inspectors often have to go in to ensure they achieved full coverage, defeating the purpose. Through Flyability’s Inspector software, Elios 3 users can create a 3D map that shows exactly where the drone flew.

“Inspectors might see a defect two minutes into footage inside a boiler, but can’t tell exactly where it is. They might do manual things like notice a seam or weld on a wall that’s three meters away, so they’re guestimating where the defect is,” Dukowitz said. “It’s inexact and time consuming. With Inspector software, you can geolocate where a defect is as you’re flying through and reviewing footage. You can tap on a point of interest and not only see a photo capture, but also a 3D model that shows where in space the defect is located, and you can share that with the maintenance team.”

Though a more complicated application, ultrasonic sensors are also being flown via drone, Dukowitz said. If engineers want to see if a stainless steel tank is degrading, for example, they can fly a drone with one of these sensors to measure the metal’s thickness.

Another use gaining popularity in the energy sector is gas leak detection, Avitan said. With methane emissions now being measured and companies fined for leaks, there’s a big push to find and fix them early. Drones carrying optical gas imaging (OGI) sensors have become the fastest way do that. Sending out systems like the Air Max from Percepto to inspect pipelines and other assets gives energy companies a better grasp of the site and where repairs might be necessary.

Drew Smith, founder and CEO of Lone Star Drone, flies the SIRAS UAS for these and other types of inspections. The drone’s OGI sensor can quickly determine where different gases are being emitted, which is much safter than suiting workers up and sending them out with a sniffer to look for the source. Leaks are found quickly, saving time, and there’s less human exposure.

“Our oil and gas customers have to produce more in a safe way and be more profitable, while at the same time almost all of them have front and center being better stewards of the environment,” Zafuto said. “When you think about drone inspections, it starts to address all those challenges.”

Utilities

Utility companies are expanding their drone programs, using the technology for transmission, distribution and substation inspections, evolving from the early days of focusing on powerlines. They’re looking for defects, vegetation encroachment, sagging lines or anything that could lead to an outage. Recently, they’ve started correlating the information they get from those inspections with other information, such as LiDAR data, Zafuto said.

Teams are using insights gained from drone flights for immediate action, said Jackson of Vision Aerial, the company behind the SwitchBlade-Elite and Vector aircraft. If they see a broken cross beam, for example, they can send someone out to make the repair right away.

Utilities are flying thermal cameras to identify hot spots, Brodbeck said, finding issues that never would have been spotted with the naked eye.

Southern California Edison (SCE) leverages drones to inspect overhead transmission, distribution and generation equipment in high risk fire areas, conducting about 250,000 inspections a year, Media Relations Advisor Ben Gallagher said. While they do have a few internal pilots, most flights are performed by service providers.

When there’s an elevated risk for wildfires, SCE conducts public safety power shut offs, proactively deenergizing the lines, Gallagher said. Dry vegetation near the lines combined with high winds are an example of conditions that create an elevated risk. Before re-energizing the lines, a drone inspects the area to make sure any threats have been eliminated.

Utilities are also using AI to identify common issues so they can quickly generate work orders and make necessary repairs, Zafuto said.

“Old or damaged infrastructure is the leading cause of wildfires, especially in California. With drones we can prioritize which assets need attention first,” Jackson said. “We want to be No. 1 for stable infrastructure, and that means fewer issues, fewer blackouts and more reliable energy, and that can extend from electric transmission and distribution to renewable with wind, solar and even water energy.”

Solar and Wind

Clean energy is another area relying on drones to help keep assets up and running. Smith flies thermal sensors to quickly inspect large solar farms in search of malfunctioning panels, for example. A bright strip along a panel indicates a burnt out diode array, which could mean there’s something wrong with the wiring for the panel that feeds into it.

Percepto recently received a waiver from the FAA to perform BVLOS inspections at a solar farm in Texas without a visual observer, Avitan said, with drone operations approved for up to 200 feet above ground level. The company has been working on this approval for nearly four years, and Avitan calls it the “Holy Grail” and the key to maximizing return on investment. Such flights are made possible through the platform’s automated detect and avoid cycle.

“If you have a solar site in the middle of nowhere, you normally would have to send someone out to look at the drone and mitigate the airspace,” he said. “Solar sites and wind farms want to reduce any operational expense, and sending someone out to the site is an operational expense. The drone also makes supply chain more efficient. If something breaks or there’s an anomaly, the drone can get a picture of what it looks like so the guy replacing it knows what equipment he needs, making the repair cheaper and more efficient.”

Drones are also routinely inspecting wind turbines, Smith said. Thermal imaging detects heat generated from problems like bad bearings. Cracks in the fiber glass housing and warpage in the wind blade are other typical analomies drone imagery captures.

INFRASTRUCTURE INSPECTIONS

Carrying RGB cameras to collect images, thermal sensors to pick up heat signatures and LiDAR sensors to create 3D point clouds, drones are making building and bridge inspections more efficient and safer, Qii.Ai President and CEO Michael Cohen said. Acoustic sensors are being added to the mix for sound testing, diagnosing concrete health, while ultrasonic sensors are measuring steel thickness.

Many of Qii.AI’s customers use the digital platform to automatically detect engineering problems using AI models. The biggest issue with steel infrastructure is corrosion, Cohen said, and with concrete it’s cracking. Once defects are found, clients receive a condition assessment of the asset to determine where their biggest problems are, how to fix them and how much repairs will cost.

Thermal inspections via drone have become standard, Raafat said, detecting heat loss in existing buildings and after envelope work is complete for new builds. Drones can quickly fly over the roof and around the building, and communicate any areas of heat loss to the envelope consultant in real time. The consultant can then determine if the heat loss is normal or if further investigation is required. This saves time and helps ensure new buildings are energy efficient.

About a year ago, Windover Construction invested in LiDAR, and recently won a 2022 Autodesk award for inspection work completed with the sensor and Autodesk software. The team flew a 120-year-old historic building, inspecting it and documenting the roof so it could be rebuilt later. The plan was to add two stories to the building, and then place the new roof.

After the roof was demoed, drone LiDAR captured the remaining structural elements, including existing walls and columns.

“Using the drone LiDAR data we created a model drawing and gave it to the folks manufacturing the new steel, and told them to design the steel based on the exact dimensions the drone LiDAR captured on site,” Raafat said. “We made sure every beam being built in the factory would fit perfectly when placed by the crane within the existing walls.”

With thermal roof inspections, splotches will show up on the imagery where water has leaked into the substrate, Smith said. These areas might retain more heat or cool faster. Seeing where the moisture intrusion is exactly enables crews to repair those areas rather than replacing the entire roof—a huge cost savings.

Smith creates digital twins of bridges to detect problems that might not be visible to the naked eye. He inspected a series of bridges in Florida, looking for rust and concrete fissures, as workers on a neighboring bridge did the same, but without drones. The men loaded into a bucket truck hanging over the side of the bridge to perform the inspection. At one point, the truck started to lean too far, creating a dangerous situation.

“The guardrail was supporting the truck, and that was the only thing that saved those workers,” Smith said. “We were on a neighboring bridge providing a more detailed inspection with no risk to human life.”

LEVERAGING DIGITAL TWINS

Digital twins are what Smith describes as the future of drone technology. These 3D models provide a real-world representation of an asset that can be set next to or over existing CAD or design files.

Digital twins preserve the conditions as they are for future analysis, allowing engineers to ask more complicated questions, Carey said.

These models allow simulation, Zafuto said. If an asset owner wants to increase throughput for an asset, the digital twin makes it possible to prognosticate how the asset will perform, if it will impair the asset and if it will accelerate the need for regular maintenance.

Raafat recently collaborated with Autodesk on a project at a local college, using a new program to incorporate all the data about a particular asset and what’s inside into a digital twin, including information collected by drone. By clicking on web-based links embedded in the model, they can see details on light fixtures and plumbing, for example, or who built the roof and when it was placed.

“This is revolutionary,” he said, “because it’s helping clients who are not as good as we are at viewing 3D models.”

Smith recently completed a 23-mile pipeline inspection in the Wyoming Badlands, gathering imagery that showed where insultation had broken down. He created a digital twin with the imagery showing where repairs were needed. Because of the vantage point, this wouldn’t have been possible without a drone. His team is also developing a digital twin of an entire oil and gas facility that a client wants to use for training.

“Digital twin adoption is growing exponentially,” Cohen said. “They allow you to understand what’s in your space and to collaborate with others around you. In the past people would have had to walk the site. Now, it can all be done on a desktop.”

LOOKING AHEAD

Every drone program Carey sees is growing. With larger budgets, more hardware can be purchased and more pilots brought on, whether in-house or through service providers. As programs grow, inspectors and engineers will extract even more from the datasets created, and share data across departments. AI will get smarter and insights more robust.

“Imagine a digital twin example at a refinery where drones are flying every day, making point clouds and maps, and that information is then populated to a security manager in a dashboard that shows changes and the location of changes detected,” Carey said. “The system will analyze the information and display it along with all the other sensor data, so it becomes part of an overall solution to see what’s happening on a site.”

The technology will get cheaper and easier to use, further driving adoption, Brodbeck said. It won’t be long before every energy company has a drone program, either in-house or contracted out, routinely using the systems to complete inspections.

We’ll continue to move toward automation and remote operations, Avitan said. Centralizing information will become easier, allowing large companies to gather data at multiple sites and store it all in one location. The dashboards created, which will house information from other sources as well, will provide a more wholistic view of asset health and what’s happening on a site. Ultimately, assets will be better maintained, improving productivity and safety. Simply put, our infrastructure will become more reliable.

“This all leads to increased efficiency that goes beyond just capturing data with the drone,” Zafuto said. “It’s really starting to speak to a prescriptive and prognostic approach to building out the asset lifecycle, including maintenance and retirement.”