Laser scanning is becoming an instrumental part of the transportation industry, with agencies, local governments and OEMs among those leveraging the ever-evolving technology for a wide range of applications, including creating 3D maps for roadwork projects, providing the foundation for smart cities and detecting objects for autonomous vehicles.

While LiDAR isn’t exactly a new technology, its recent evolution has opened up use cases across industries, transportation among them.

Laser scanners can be deployed on a mobile vehicle or drone to scan a right of way, carried on foot to gather data in a subway station, integrated into smart infrastructure designs to enhance safety or put into an autonomous vehicle for object detection. Today’s LiDAR solutions are a far cry from the bulky, expensive systems of the past, and departments of transportation, government agencies and OEMs are starting to take advantage of the new possibilities.

As the scanners have gone down in size and price but up in accuracy (in part because of the work within the automotive industry), they’ve also gained flexibility. Many surveying professionals, for example, are comfortable using terrestrial and mobile LiDAR, have been doing it for years, but today can add drone-based LiDAR as another tool. Recognizing the need, manufacturers are now developing solutions that can be easily swapped out between ground and air vehicles, adding another layer of flexibility and convenience.

Drone-based LiDAR mapping is the latest evolution of the technology, allowing professionals to quickly and easily create 3D maps of say a road or a right-of-way, penetrating vegetation to get down to the bare earth—something that isn’t possible with photogrammetry alone.

Drones aren’t meant to replace the more established solutions, but they do offer a different perspective and are able to gather data in areas ground solutions can’t reach, and do so cheaper and quicker than manned aircraft can.

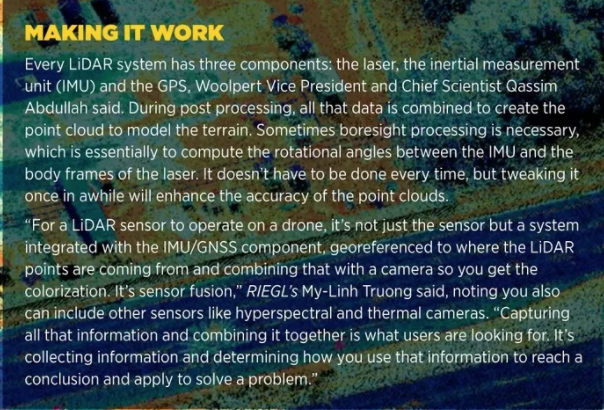

“It will get to a point where clients who have a mobile-based system driving on highways will have a UAV-based LiDAR in the trunk,” said My-Linh Truong, division manager, unmanned laser scanning for RIEGL USA of Winter Garden, Florida. “After they scan the lanes, they’ll set up the drone-based LiDAR to capture the rest of the terrain and through data fusion merge the two data sets together to really get a full picture.”

LiDAR now touches just about every aspect of transportation. “We are just in the beginning of a full transformation of the way we think about transportation,” Ouster VP of Smart Infrastructure Itai Dadon said, “and how we are going to be able to enhance all the metrics around transportation.”

INFRASTRUCTURE

More Work on Roadways

The team at Geodetics, an AEVEX Aerospace company out of San Diego, has seen an uptick in infrastructure-related LiDAR requests in recent months, Vice President Bob Stadel said, largely because of President Joe Biden’s infrastructure bill that has money flowing down to state transportation agencies.

Many are interested in the company’s higher-end LiDAR-based systems, which, while a little bigger, provide better accuracy, with point clouds within 1 or 2 centimeters. They also want solutions that can be easily swapped between ground- and drone-based systems, and, in some cases, are integrating photogrammetry and multispectral sensors for even more robust end products.

Their LiDAR-based systems, deployed on vehicles and UAS, are 3D-mapping city blocks, looking for areas that need upgrades, and completing projects such as road corridor surveys and bridge inspections.

Getting the Full Picture

Drone-deployed LiDAR is the next evolution of the mobile systems, said Mark Treiber, product manager for Teledyne Geospatial. Drones provide a view from above that goes beyond the road, but with a lower point density.

“With a UAV, you’re filling in a lot of those shadows you miss from a vehicle,” Treiber said. “For example, if there’s a fence on the side of the road you can capture data beyond it or beyond the parked car that previously was shadowing the area you were surveying.”

A mobile LiDAR system gives surveyors the accuracy they need for design grade, said Qassim Abdullah, vice president and chief scientist for Dayton, Ohio-based Woolpert, while drone-based does not, at least not yet. But drones offer a cheaper, more efficient alternative for data collection off road and in smaller site areas where varying levels of accuracy are required.

Drones can fly along rights-of-ways to map an area before an expansion or new build so workers know where poles are and if there are any changes in grading or drainage that could lead to flooding during a rainfall, LiDAR USA CEO Jeff Fagerman said. While typically the accuracy isn’t quite there for picking up the small cracks and fissures engineers look for in road inspections, what a drone can cover from above provides a more complete view, without the cost of hiring a manned aircraft.

Merging data from different types of LiDAR deployments also helps paint a more complete picture. One of LiDAR USA’s customers, for example, recently purchased a LiDAR system to map a roadway with a pedestrian bridge beside it, Fagerman said. The customer can scan the road with a mobile unit and then put a backpack on and walk the LiDAR across the bridge, collecting points from different angles and gaining access to a structure that’s inaccessible to cars. A drone could be deployed in this scenario as well.

Measuring for vegetation health and encroachment on roadways and rights-of-way is another area where aerial LiDAR mapping is taking off, said Greg Lary, senior director, business development, commercial business for AeroVironment. It allows agencies to be proactive and find spots where vegetation needs to be trimmed back before it falls on a vehicle during a windstorm, for example.

Most departments of transportation are using LiDAR in some way, Truong said, with one of RIEGL’s customers, the Michigan Department of Transportation (one of the early adopters of drone-based LiDAR), deploying one of RIEGL’s systems to supplement the mobile-based solution they’ve been using for years.

Drone-deployed LiDAR also can be helpful for inventory assessment, such as road signs, or for modifying an interchange, Truong said.

“The LAS file outputs are brought into third party extraction software for analytics, looking at things like curbside and the slope of the road,” Truong said. “The reflective properties of the LiDAR are also able to tell how reflective the paint strips are on the roads and can assess how reflective the coating is on road signs.”

Slope analysis is another use case for drone-deployed LiDAR, Abdullah said, an application that’s not really possible with a mobile LiDAR system. Scans from a truck can’t reach a cliff that’s 200 or 300 feet up, but a drone can, gathering the information needed to detect if a landslide is imminent.

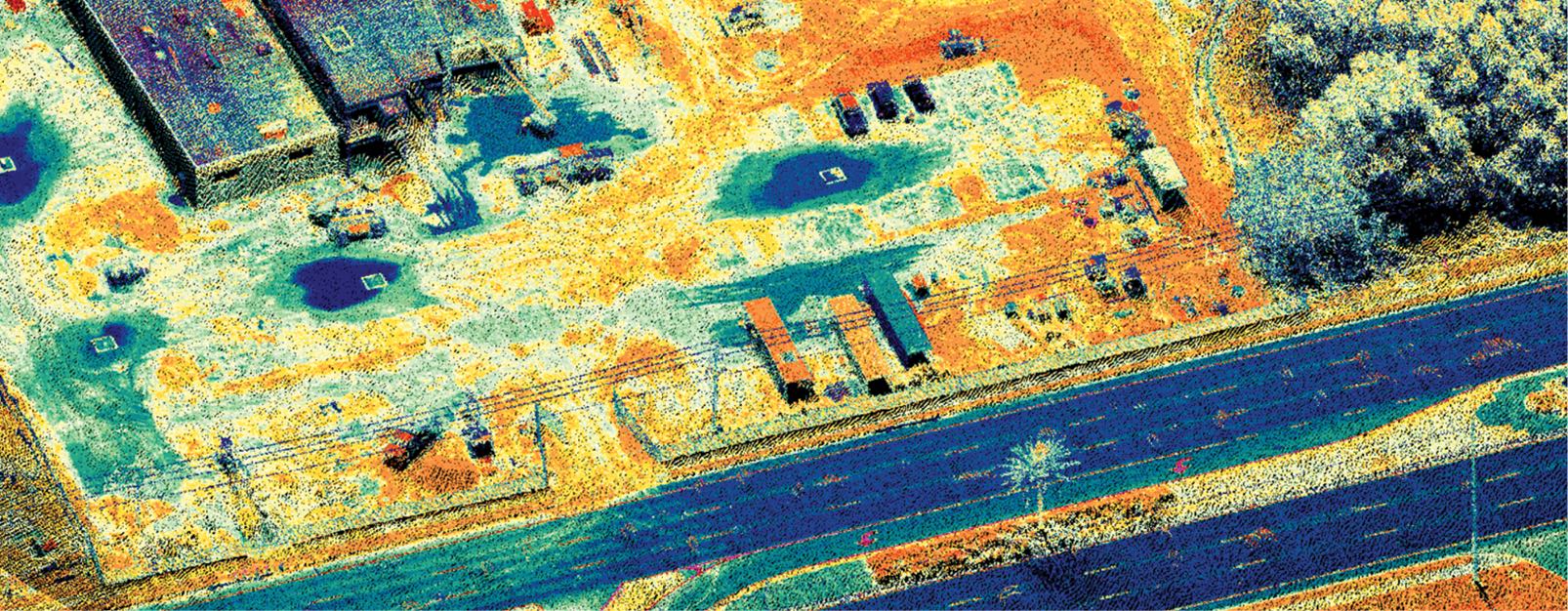

During road construction projects, LiDAR also can be flown on a drone to measure the levels of materials that have been moved in and out of the site, noted Stefan Hrabar, CEO and co-founder of Australia’s Emesent, as well as to monitor progress throughout a project. This can lead to significant savings on material costs.

Denis Labelle, operations manager for All Roads Construction, of Surrey, British Columbia, hasn’t invested in a drone yet, but does see the value of tracking quantities. For now, his crew relies on another LiDAR-based technology: the SmoothRide road resurfacing solution from Topcon Positioning Group. The technology combines LiDAR with machine control, allowing for a more efficient process than traditional methods.

Creating a SmoothRide

Labelle began using Topcon’s SmoothRide a few years ago after winning a large resurfacing project on the Trans-Canada Highway, with stringent specs, working time limitations and heavy fines for going past them. They needed a system that improved efficiencies so they could get the job done on schedule. Not only did the company finish on time, it won the B.C. Transportation Contractor of the Year Award of Excellence for its results.

Through SmoothRide’s LiDAR scan, companies like All Roads Construction can create a replica of a road that needs resurfacing, said Mark Larranaga, who runs Topcon’s SmoothRide program in the U.S, giving them an idea of challenges with the surface and allowing decisions before work even begins. The LiDAR scanner, mounted on a vehicle, collects billions of points, and that information goes into a software package for analysis and design.

In another program, project managers can make adjustments to smoothness and cross slope and look at material management to make sure they’re meeting project specs, Larranaga said. When the manager is satisfied with the file created, it goes into a mill or paver that, using machine control, puts down or takes out the material to create a smooth road surface.

Labelle has used SmoothRide to get a better handle on material needs to avoid overspending, to show clients exactly why their spec requirements aren’t obtainable, to reduce the number of people they need for a job and to provide proof of the work’s quality.

“It allows you to create as builds of the work you’ve done,” Labelle said. “When you take the original scan, it shows cracks and road damage, and if part of the road has settlement that needs fixed. You can reference that LiDAR scan to show the patch they didn’t want fixed as part of the project. Before, you might not have been able to remember if that patch was there before you started the work or not. Now you have proof.”

Drones on Bridges

Bridge inspections are another area LiDAR is taking hold, with mobile and terrestrial units leading the way. There is, however, a place for drones; it’s just a matter of working around the challenges.

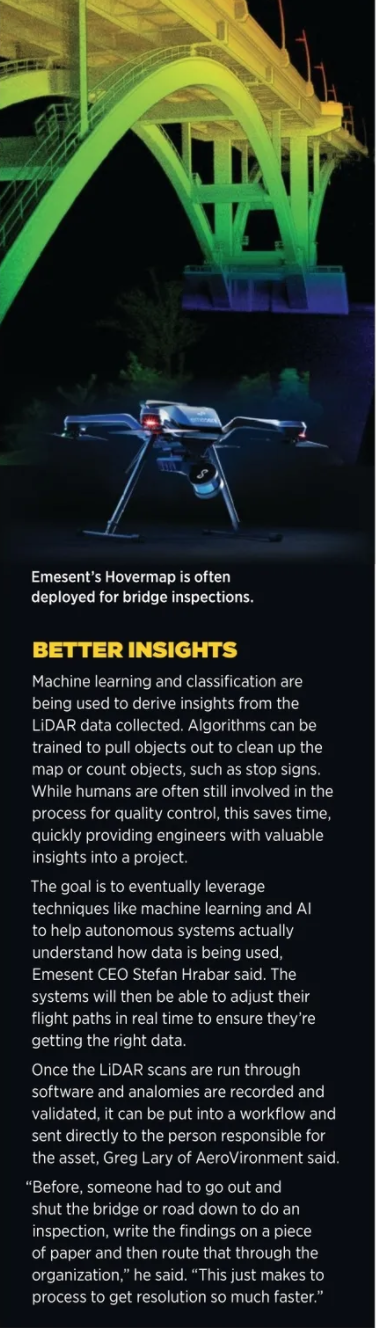

GPS, or lack of it, is one issue. Emesent’s Hovermap is often used for bridge inspections because it can get to places with limited or no GPS. Instead of relying on GPS, Hovermap uses real time data from a Velodyne LiDAR to generate a map and navigate the drone, Velodyne Chief Marketing Officer Sally Frykman said, by running a simultaneous localization and mapping (SLAM) algorithm.

The Velodyne pack provides a full-circle view, Hrabar said, which means users don’t have to worry how the sensor is pointed when flying under a bridge. This field of view also allows for collision avoidance. There’s a virtual bubble created around the drone so it won’t get too close to the structure, which is often a challenge during bridge inspections.

Many drone-deployed LiDARs don’t have the accuracy required to identify problems on bridges, Fagerman said. Photogrammetry is typically best for getting up close to see cracks and fissures, though there are some high-end LiDARs that can take on the job.

“We have a Texas customer who has taken beautiful pictures of metal expansion bridges and can use those maps to do inspections that would otherwise take months of people crawling around on those bridges,” Stadel said. “They’re looking for defects at the centimeter level to see where the wear is and how it’s changing. It takes a high-powered LiDAR because of what you have to look for and how small the details are.”

Combining photogrammetry with LiDAR gives inspectors the best of both worlds, Hrabar said. A solution like Hovermap can generate the 3D shape of the bridge and the high res images pick up the small details. The inspection images can be pegged onto the 3D shape, so if inspectors find a crack, for example, they can locate exactly where it is on the structure.

Taking that data and using AI to detect analomies, whether on a bridge, roadway or railway, allows for quicker detection, leading to immediate repairs that keep small problems from becoming big ones, Lary said. Scanning these assets over time allows for a more effective way to operate the maintenance budget, prioritizing repairs based on severity.

“You can scan a bridge this month and again six months later, look at the digital twin of that structure and at the measurement shifts or crack detection, and say that’s not as severe right now, so it’s classified as minimal,” Lary said. “That allows them to say we’re going to defer that to next year and then budget for it.”

Lighting conditions also can be challenging for bridge inspections, Hrabar said, but LiDAR works day or not, and in rain, fog and snow. That’s one of the benefits it has over photogrammetry. The need for fewer passes over a structure is another.

“With photogrammetry you have to make sure you have sufficient overlap, so you have to take thousands of images for photogrammetric reconstruction,” he said. “With LiDAR, you don’t need image overlap, so you can fly more efficiently and cover the area more quickly. And post processing is quicker because you’re not doing photogrammetric calculations. LiDAR also has return capabilities, so you get readings on the first and last thing it hits. You can use that to remove points and filter out vegetation.”

Working Together

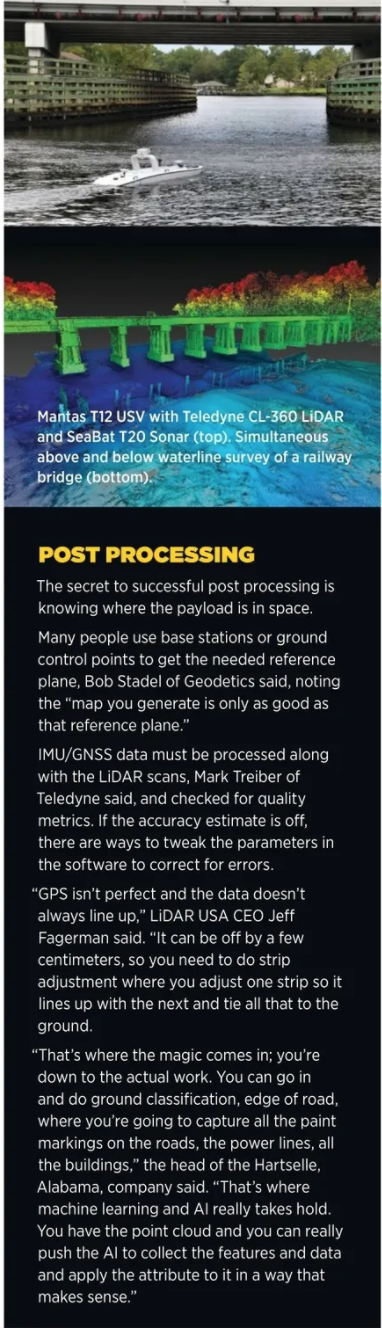

Bridge inspection is another example of an application that’s ideal for a multi-purpose LiDAR system, Treiber said.

In addition to mounting a LiDAR on a UAV, it might also be beneficial to mount one on a boat, manned or unmanned, to go underneath and combine the sensor with a sonar survey. This makes it possible to capture everything around the bridge, above and below the surface. The benefit of using unmanned underwater vehicles, of course, is the ability they have to get into places too dangerous or tight for crewed vessels.

The datasets can be combined together in LiDAR processing software, taking into account the different accuracies.

“If you’re combining LiDAR with imagery,” Lary said, “oftentimes people will colorize the LiDAR, but if you want to colorize a bridge you’ll need to use direct geo referenced colorization of a LiDAR point cloud, where your LiDAR processing software also has access to camera imagery so it can colorize the sides of the bridge rather than just the top down of a bridge.”

Beyond the Roads: Railways, Subways, Airports

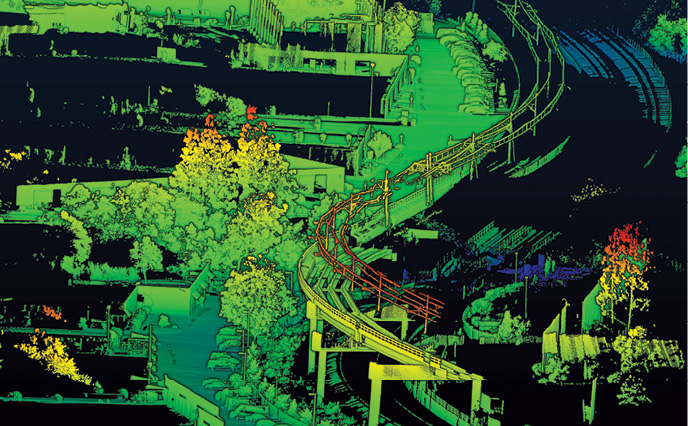

Railway inspections via LiDAR are similar to those on a roadway. The systems can be mounted on a vehicle or a drone can look at rail ties.

“The drone-based LiDAR definitely can be used for that,” Abdullah said, “because it has enough vertical accuracy and it provides a detailed 3D model. So, if you have a dip in the railroad because something broke, you can pick it up with that.”

These railway systems have been around for 100 years or more, said Brent Schwarz, vice president of business development for Luminar. They can’t be replaced, making it critical to find technologies that make them more efficient so we can get more out of them. LiDAR does that.

Security is another use. Luminar’s automotive grade LiDAR, which provides high-resolution data in real time, can be used as perimeter security, what Schwarz describes as a virtual fence. It can be deployed underground in a subway station as well, with the LiDAR placed somewhere in the station collecting data.

Through this virtual fence, LiDAR can detect if someone gets within 5 feet of a platform, for example, and sound an alarm. It also can count how many people are on the platform to make sure there isn’t a safety issue.

“LiDAR takes measurements, so it does a great job of counting and estimating distance between people and objects,” Schwarz said. “It can do the same for trains, keeping separation between them. Trains now are run inefficiently; they do it by time. LiDAR can help them make a more smooth transition in and out of the station, increasing throughput. They won’t need as many trains because they’re operating more efficiently.”

With limited to no GPS and plenty of tight spaces, deploying drones or ground robots in subway stations can be challenging, Hrabar said, and Hovermap is one solution to this challenge. Workers can walk the station as well, carrying the LiDAR to collect data and merge all the information together during post processing.

LiDAR can be deployed as a survey tool after an incident, Hrabar said, say for a blockage on the track or a crash, to map what’s happened without having to send anyone in.

Moving to the airport, runway maintenance is another critical area where LiDAR can play a role, particularly if flown on a drone, Lary said. Taking scans between flights to map and measure runways, taxiways and handling aprons could alert crews to analomies such as cracks or debris. Of course, getting permission to fly in restricted airspace could be a challenge, as is integrating these inspections into busy airports. But providing “near instantaneous awareness to the operation and maintenance team,” is invaluable, Lary said.

“The control tower can shut down a runway and inspect it literally down to a georeferenced area instead of scanning it with their eyes,” he said. “They’ll know within roughly a 10 or 5 meter radius where an anomaly is, so they can briefly shut down the runway, go right to the area and grab it.”

THE DRIVE

Building Smart Infrastructure

While there’s still some time before autonomous vehicles routinely drive along roadways, progress is certainly being made toward that goal, with many vehicles now featuring advanced driver-assistance systems (ADAS) capabilities. As the way we get around starts to change, so too should the infrastructure—and now is the time to reinvent it.

“How do you create systems that talk to each other and have synergy, rather than two different silos,” Dadon said. “It’s rethinking about standards. You can see that in the evolution of V2X, vehicle-to-anything communication, and V2I, vehicle to infrastructure. We’re also seeing more use of advanced cellular networks for these systems that are becoming ubiquitous. We’re talking about 5G as an enabler of use cases because of its reduced latency and increased throughput, and the ability to tap into that network wherever we are in the world.”

Developing smart infrastructure has become part of that, with LiDAR playing a key role. Through smart infrastructure, assets like highway signs, stoplights and on-ramps can sense what’s going on around them and use that information to trigger an outcome, Dadon said. LiDAR can be placed at an intersection, for example, to detect when someone is trying to cross the street at the same time a car is approaching. The pedestrian and car are then both alerted, possibly through flashing lights, averting a tragedy. The alert is enabled by the 5G network.

Edge-computing is a critical component of smart infrastructure, bringing the brains as close to the data as possible, Dadon said. Data also can be analyzed later, with many cities interested in the number of near accidents that occur in specific areas over a certain time period. If a high-risk intersection is identified, the city can act, which might mean changing the timing of the traffic light.

Working from San Francisco, Ouster’s digital LiDAR has been placed in cities from Chattanooga to Hong Kong to help keep pedestrians and cyclists safe day and night, creating a communication with the infrastructure that will become even more critical and more defined as we move to fully autonomous vehicles.

“If you know your data is accurate and true at all times, this is a gold mine, this is the Holy Grail of autonomy and smart infrastructure,” Dadon said. “That is also coupled with the ability to see things as they are. Our world exists in three dimensions and many of the other sensors, like cameras, only provide information in two dimensions. We need to be able to detect objects and then understand where they are in space no matter the weather or life conditions. That’s why LiDAR is really important.”

Smart infrastructure also can save motorists time, fuel, and wear and tear on their car. For example, instead of sitting at a red light when no one is around, a driver (or autonomous car) can be alerted that there’s no need to stop, Schwarz said.

Velodyne’s LiDAR sensors are also being used in intelligent infrastructure and smart city design, which are positioned to be among “the fastest growing LiDAR markets in the next several years,” Frykman said.

Getting to Automation

LiDAR is becoming more common in autonomous vehicles and ADAS, and while Frykman believes widespread adoption is still a ways out, it’s coming.

Schwarz expects to see more vehicles reaching Level 2 autonomy in the coming years, with LiDAR playing a key role in that. Levels 3 and 4 will gradually come next, likely in trucks first. Shuttles, delivery vehicles and eventually cars will follow suit.

LiDAR scans of roads and cities are also critical, Fagerman said, and can be used to build high-definition maps for the autonomous driving market. While that’s not a big market for LiDAR USA just yet, it’s growing.

And as consumers become more aware of LiDAR and the safety it offers in terms of reaching autonomy, providing object detection no matter the weather condition, those who will be traveling in these cars or shuttles will demand it.

“That, together with the appearance of more reliable LiDAR technology with better performance at a lower cost, is the inflection point where the adoption of LiDAR becomes more prevalent,” Dadon said, “and almost a standard for this new platform of vehicles.”

Systems that transport people and goods are other areas where LiDAR will shine, allowing vehicles to see what’s around them in 3D. The sensors offer the much-needed detail that radar and cameras don’t provide across all weather conditions—a must for safe travel.And as people see more big players highlight their work with autonomous vehicles and the LiDAR systems they’re integrating, they’ll be more accepting, helping to move the industry forward.

THE FUTURE OF TRANSPORTATION

As the commercial UAS market continues to mature, more departments of transportation will adopt drone-deployed LiDAR to supplement the data they get from mobile scans, Truong said. It will start to become a standard application that adds efficiencies and provides workers with richer datasets.

The accuracy of drone-based LiDAR will eventually match or beat the mobile mapping system, Abdullah said, making it suitable for design grade. Endurance will also continue to increase, giving drones the ability to go from scanning a few miles at a time to 20 to 30—and that, Abdullah said, “is the game changer—when you can replace the current practice of using manned aircraft with unmanned.”

The LiDAR technology behind smart cities, where autonomous shuttles and cars will become commonplace, will make it possible to have a 3D model of the environment updated constantly, Hrabar said. Robotic systems and drones will be on standby, ready to scan and map, feeding the data back into a central depositary. Engineers and other interested parties can view the data in real time or go back to older scans to see how an infrastructure has changed. This constant monitoring will help ensure the infrastructure stays in good repair.

There also will be more collaboration, Hrabar said. Today, data collected from ground robots and drones are merged during post processing. In the future that will happen in real time.

A little further out, say 10 years, Stadel sees a world where we not only have smart cities, but drones that are flying overhead in safety corridors, transporting goods and people.

“The best way to map those corridors is to have smaller drones flying back and forth every day using digital twin technology for change detection,” Stadel said. “This was a safe corridor yesterday, but somebody put up a crane and now the delivery drone can’t fly through.”

As LiDAR is deployed on both vehicles and throughout cities, there will be digital twins of the infrastructure and roads, the poles, the markings—basically everything.

“This will enable a new way of thinking about how we do our planning,” Dadon said. “And how we understand the impact of any change we bring into our infrastructure before we do it to actually get the best design and the best outcome for transportation. That is enabled by the introduction of LiDAR.”