Growers are starting to think differently about how they manage their farms and the way they produce the food that ends up on our tables—because they have to.

Labor shortages, fluctuating input prices and a focus on establishing more environmentally friendly practices are among the factors making the current landscape more challenging than ever before. Consequently, it’s vital to improve efficiencies and cut costs. Drones are among the tools helping producers, both big and small, do that.

Increasingly, UAS are being deployed to scout fields year-round, providing valuable insights. With these solutions, growers can quickly learn about plant health, determine where weeds are threatening their crop, create prescription maps for spot spraying and precisely spread cover crops. The list of applications keeps getting longer, and as farmers become more comfortable with the technology and see the benefits it can bring, drones will have an even bigger impact on maintaining our food supply.

Increasingly, UAS are being deployed to scout fields year-round, providing valuable insights. With these solutions, growers can quickly learn about plant health, determine where weeds are threatening their crop, create prescription maps for spot spraying and precisely spread cover crops. The list of applications keeps getting longer, and as farmers become more comfortable with the technology and see the benefits it can bring, drones will have an even bigger impact on maintaining our food supply.

“Producers are facing so many variables, and they need something to fight back. Drones are helping them fight back,” said Olivia Soares de Camargo, ag specialist and customer service and satisfaction engineer at senseFly, the Swiss company behind the eBee drones. “Drones make growers more efficient, so they’ll be able to invest fewer resources to produce the same amount, or the same amount of resources to produce more. That’s why they’re the future. Every single producer is eventually going to have a drone because it’s part of becoming more efficient.”

Instead of flying themselves, many growers are hiring drone service providers, either on their own or through a co-op. The agronomists and crop consultants typically operating the systems rely mostly on RGB cameras, though some deploy thermal sensors as well. The more expensive multi and hyperspectral cameras and LiDAR can provide valuable information, but for now are mostly used by researchers.

Drones have become an important component of precision agriculture, and a critical part of an ecosystem that keeps farms of all sizes running smoothly and more sustainably. Already the prescription maps they create are directing tractors and rigs, but eventually all the autonomous systems will work in harmony to complete various jobs. These are the types of technologies and interactions that will help secure the world’s food supply moving forward.

YEAR-ROUND USE

While there are plenty of ways drones can provide benefit during the growing season, the systems also can be used as efficient, accurate surveying tools year-round. Drone imagery gives producers valuable information about land before they purchase it, for example. UAS can be quickly deployed to check borders, and to show which parts of the property are usable and which are not.

In preparation for the season, drones provide insights into the land’s current

topography, Soares de Camargo said, which is critical for water management and implementing proper irrigation.

“Farmers are using drones to map the fields when bare to install tiling for drainage,” said Mike Winn, CEO and co-founder of San Francisco-based DroneDeploy. “With a drone you can map the elevation of every point in the field and do it 10 times faster than traditional surveying technology.”

Knowing which way water drains is also crucial when determining planting direction, Soares de Camargo said. Crops should be planted in a way that preserves the soil and ensures water won’t wash everything out.

UAS also can be flown across fields to identify rocks and boulders that might impede large equipment, said Mike Dowell, founder of Mobile Recon Systems out of Grand Forks, North Dakota. Workers can then be sent out to remove the barriers and expand the planting area.

After the harvest, there are plenty of insights growers can gain from data collected throughout the season, said Mike DiPaol, chief commercial officer for Taranis, a Israel-Brazil-U.S. company that offers a content network through its SmartScout and Taranis CONNECT solutions. Analyzing this data can inform what changes should be made to get more out of inputs for higher yields.

“Now we have correlation and causation to help us understand what led to the outcome,” DiPaol said, “and how to mitigate in-season as well as plan for next season to be better.”

IN-SEASON INSIGHTS

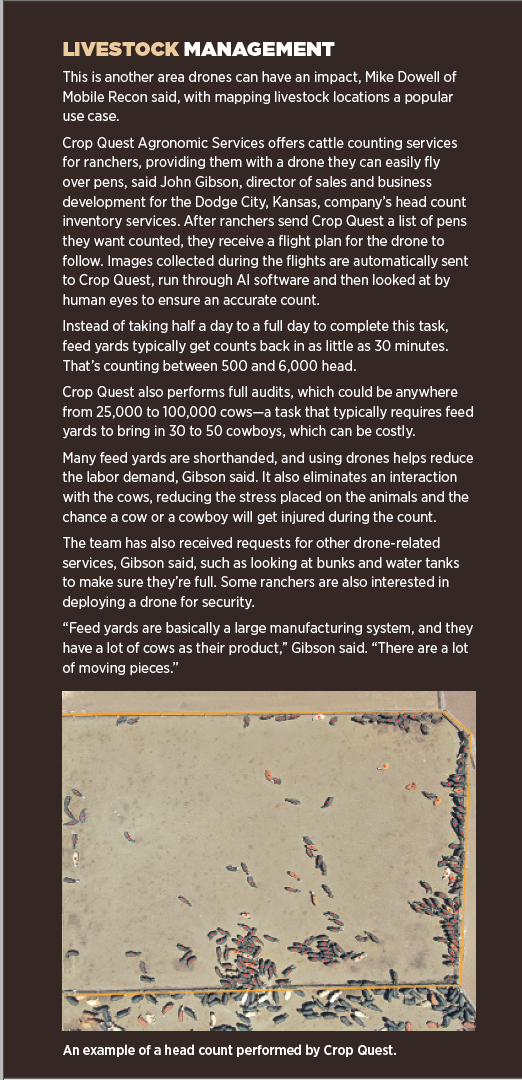

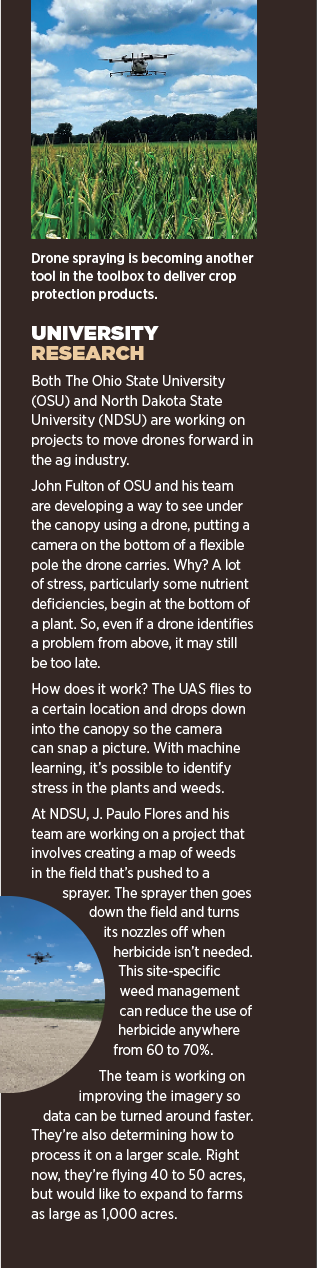

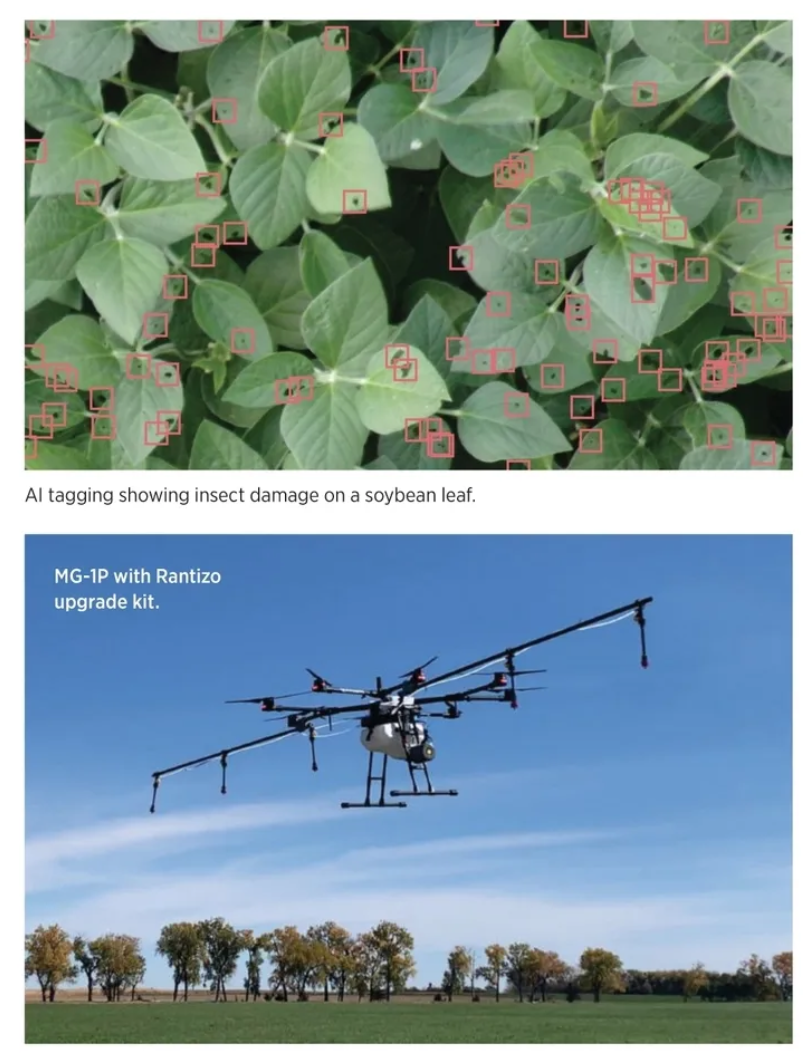

Scouting is the oldest and most common use for drones on farmlands, with images taken from the RGB cameras onboard telling growers if there’s something wrong with the crop, said J. Paulo Flores, assistant professor in the Department of Agricultural and Biosystems Engineering at North Dakota State University (NDSU). While they may not identify the exact problem, growers know where to go to investigate further and can determine a course of action from there.

That basic use has transitioned, with more intelligence now built into the processing and analytical side, said John Fulton, a professor in Food, Agricultural and Biological Engineering at The Ohio State University. Producers can use drone imagery to perform stand counts early in the season, spot nutrient deficiencies and, through AI, identify the exact weeds and pests threatening crops.

Prescription maps are created from this information, directing equipment and workers to locations that need more fertilizer, fungicide or other mitigation. This results in fewer chemicals sprayed in the field, allowing for more sustainable farming practices while also significantly cutting costs.

Multispectral cameras can identify disease or other health issues in crops using bands that absorb specific colors, Soares de Camargo said. These images are often delivered as vegetive indices, such as NDVI, that tell growers about problems they likely wouldn’t see until later, giving them an opportunity to save more of the crop.

The prescription maps generated, regardless of sensor used or the size of the operation, are huge time-savers. In the past, farmers and agronomists scouted fields manually to look for pest infestation and monitor crop growth, a painstaking process, said Olivia Zhou, global branding manager for China-based XAG.

“When it comes to larger farms,” she said, “it is impossible for manual workforce to cover the entire land plots, which means that some crop abnormities would be missed and thereby lead to lower crop yield.”

And producers can have access to this critical information in real time. DroneDeploy’s software, for example, uses AI to count crops and computer vision to create maps during flight. It works fully offline, so lack of cell coverage is not an issue, Winn said. Farmers, farm advisors and field reps get an immediate understanding of where problems are and can start working on solutions right away.

“It gives an opportunity for the advisor and grower involved to have valuable conversations every day and to change what they’re doing,” DiPaol said. “It gives them better, more timely information.”

SPRAYING AND SPREADING

Spray drones are finding their niche in the ag industry, with service providers typically handling the flights. These drones can be used to apply fertilizer and fungicide, as well as spread cover crops. They safely fly over difficult terrain, making it possible for growers to reach areas spray tractors and manned airplanes can’t.

Spray drones are finding their niche in the ag industry, with service providers typically handling the flights. These drones can be used to apply fertilizer and fungicide, as well as spread cover crops. They safely fly over difficult terrain, making it possible for growers to reach areas spray tractors and manned airplanes can’t.

When used properly for spot spraying, these drones can save farmers big, said Arthur Erickson, CEO of Hylio. If farmers can identify where the field needs sprayed, whether through scouting via a drone or other methods, a prescription map can be fed into the system that tells the drone where to spray and how much. This spot spraying isn’t possible with large rigs. They typically can’t be programmed to spray specific areas, and even if they could, they’d trample crops and compact soil along the way.

“After taking the high-resolution farm images, the agricultural drone can automatically identify field boundaries, plant density and crop growth status to determine the amount of pesticide use needed for the target areas,” Zhou said. “A prescription map will be generated on users’ mobile apps to indicate variations in crops and guide variable-rate spraying application of the drones. AI technology is making crop spraying as precise as the scalpel’s cut.”

Even with autonomous tractors on the horizon, drones will remain more effective for spot spraying, Erickson said.

“If there’s a heavy rain on corn or soybeans, fungus usually follows shortly after,” Erickson said. “Farmers want to spray right away but can’t because their tractor will get stuck in the mud, and that costs money.”

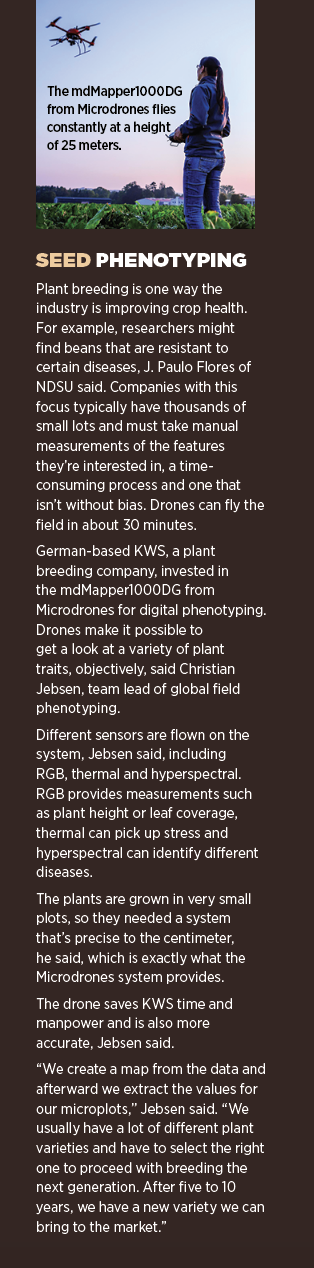

Waiting two or three days to spray could mean all the difference to a grower, said Emily Carlson, marketing manager for Iowa City’s Rantizo, a spray drone service provider that recently received FAA authorization to operate the first drone over 55 pounds for ag applications. Weeds grow fast, so it’s best to take care of them sooner rather than later.

Cover crop applications are another growing area for spray drones, Carlson said. They’re planted later in the season among the row crops, so putting big equipment in the field to spread the seeds often leads to damaged crops. Drones can use spreaders to precisely drop in cover crops between rows.

Ryan Vonder Haar and his cousin Luke Boeckman use cover crops on their farm in Illinois, and went to a Rantizo demo day in early 2021 to learn about how the service could benefit their farm. They liked the idea of putting cover crops in before the harvest rather than after, giving them a little earlier growth.

The pair saw a need for these services in their area, so they decided to become Rantizo contractors as well, forming L&R Ag. They took the training, obtained the licenses required to spray individual crops and kept busy last season mostly spraying fungicide on local farms.

Nick Williams, another Rantizo contractor, also uses the spray drones on his farm and for growers in South Dakota. Farmers have turned to him to help with weed control in their pastures, Williams said, and he expects the 2022 season to be busier than 2021.

“There’s a lot of positive curiosity about it,” he said. “There have been skeptics but once they see what we’re able to do, a lot of guys are coming around.”

In Spencer Bulman’s area in Waukon, Iowa, farmers must deal with tricky terrain. Dramatic changes in elevation make it difficult for bigger machinery to spray, so farmers were happy to hear about the services he can offer via Waukon Feed Ranch as a Rantizo contractor. They saw an instant response on fungicide as well as a lot of interest in getting cover crops in the ground two to three weeks earlier, before the row crops were harvested.

Mobile Recon Systems is focusing on cover crop seed distribution as an entryway into the ag market, CEO Tom Nickell said. In partnership with NDSU and Aerial Spreader Drone Services out of Bridgeton, Missouri, the team aims to study seed distribution from different heights for various types of crops. They’re in the planning phases of the study, gathering data about how seed is spread, and will soon move into phase two, which will focus on germination success.

“Farmers are focused on productivity, so we want to demonstrate that aerial seed spreading from multirotors actually yields enough crops and is an economic benefit to the farmer,” Nickell said. “Our end goal is to go out with a large enough UAS that can carry multiple mixes of seeds and various sensors so it can determine moisture content and heat generated from the plant to determine health, and that this area needs this type of seed mix and this area doesn’t need anything.”

With the right sensors, the systems also can be used to identify invasive species in orchards or a field, Dowell said, and to apply the compounds to eradicate the species just where it’s needed, even if it’s just one tree. By only spraying the infected areas, operators save resources and have less environmental impact while also increasing yield.

Drone seed spreaders can be used for conservation seeding, which is how Aerial Spreader Drone Services got its start. These seed mixes stabilize and replenish soil and include grasses and forbs (plant species with broadly similar growth form), said Keith Knepper, founder of Aerial Spreader Drone Services, and can be spread in pastures where wildlife and cattle graze. The company moved into interseeding cover crops into standing cash crops, corn or soybean, to enable more farmers to get them planted in the best location at the optimal time no matter the ground’s condition, and without having to wait for a manned aircraft to be available to spread the seed.

Drone seed spreaders can be used for conservation seeding, which is how Aerial Spreader Drone Services got its start. These seed mixes stabilize and replenish soil and include grasses and forbs (plant species with broadly similar growth form), said Keith Knepper, founder of Aerial Spreader Drone Services, and can be spread in pastures where wildlife and cattle graze. The company moved into interseeding cover crops into standing cash crops, corn or soybean, to enable more farmers to get them planted in the best location at the optimal time no matter the ground’s condition, and without having to wait for a manned aircraft to be available to spread the seed.

The hopper he created can hold a variety of seeds and meters their distribution,

enabling operators to dial in anything from one pound an acre—which is common for cover crop mixes with turnips, for example—all the way up to 40 to 50 pounds an acre for oats, rye and some grasses.

The company is testing the spreader on different-sized drones, including Mobile Recon’s platforms. The goal is to have larger systems carry multiple hoppers and a sprayer, with the ability to cover more than 60 acres a day. That would enable users to spread multiple species and complete a spray application, depending on what both ground and aerial sensors indicated is needed.

“It’s about performance to plan; it’s not good enough to just spread the seed,” Knepper said. “We want to put the right mixes in the right place and to see better germination.”

THE FUTURE

The ag industry is at a turning point, Carlson said. Producers are really starting to see how drone technology can add efficiencies to their workflows and improve yields, while drone service providers can add another revenue stream to their business.

“Drones are like tractors; in the beginning only the leaders in the industry purchased tractors because they had more resources,” Soares de Camargo said. “We are a bit further than that now. We are

seeing even the smaller producers going after drone technology. Like tractors, drones are going to be an essential tool that’s part of the day-to-day life of any producer.”

UAS will continue to get bigger and smarter, with the ability to provide custom applications. We’ll see more drone swarms, further improving efficiencies in the field.

Increased automation is also in the future. Erickson sees it eventually getting to the point where farmers have drone-in-a-box solutions on their property. Using a map, a drone might fly out to find problems in the field, then automatically send a report to the spray drone or rig, which then deploys to spray the areas that need attention. Other than filling the tanks and spreaders, there’s no human intervention required.

“Multiple drones will be working in conjunction with autonomous tractors,” he said. “In the next 10, 20 years, every tractor will be autonomous, and as it’s planting or plowing it will send data back to a base station that’s communicating with a drone. When the tractor is done planting, the drone knows it should put fertilizer on the new crops. A farmer or landowner becomes the top-down strategic advisor for the army of machines, giving high-level directives on where the boundaries are, what they want to grow and how tall. The robots then go and make it all happen.”

As scouting becomes more common, farmers will also have a lot more intel to work with, Fulton said, which includes accurate records of what’s emerged. They’re going to be more informed about their crop, and make better decisions that lead to higher yields.

Fulton expects drones to continue spot spraying rather than taking on large fields, but doing so can reduce the amount of herbicide sprayed by as much as 70 to 90%. That’s a “huge shift from where we are now” and a “game changer for the industry,” he said.

And drones will reduce the impact farming has on the environment, a benefit for everyone.

“We believe that drones and robots are the critical driver of sustainable agriculture,” Zhou said. “They can change the way people produce crops and prepare us for the future with adequate, safe and nutritious food.”