Acwa Robotics’ new Clean Water Pathfinder robot aims to crawl around inside active water pipes to check for corrosion and leaks, helping utilities save water and money.

While most water pipes are inspected by eye from the outside, the French startup Acwa Robotics plans to inspect them from a whole different angle—the interior of the pipes themselves.

The company has launched Clean Water Pathfinder, an artificial intelligence-powered robot capable of navigating through drinking water pipes, monitoring their condition and searching for leaks without interrupting their operation.

The Pathfinder made its debut at CES 2023 in Las Vegas, where it racked up a Best of Innovation award in the Smart Cities category and Honoree status in the Sustainability, Human Security for All, Eco-Design and Smart Energy categories.

“We are just at the inception of something really good, which is robotic work inside water pipes,” company Cofounder and Business Development Director Jean Francois Guiderdoni said, speaking to Inside Unmanned Systems at CES.

The goal of the project is to better understand and map the condition of drinking water pipes. According to Acwa, utilities around the world lose 32 billion cubic meters of clean water every year because of the poor conditions of the pipe networks. In the United States alone, that amounts to 8.2 billion cubic meters, or 20 to 40% of the total water transported.

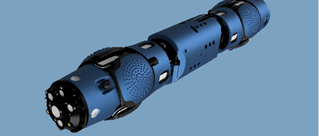

The Clean Water Pathfinder, roughly the size of a human arm, can be dropped into pipes to autonomously conduct interior surveys, using high-definition cameras, ultrasound instruments and leak detection instruments to measure pipe thickness, monitor corrosion and locate cracks or leaks.

Guiderdoni created the 14-person company in 2018 with Chief Technology Officer Jean Francois Rossi (“everyone in France is named Jean Francois,” he jokes), who was working with a wastewater treatment plant when he started digging into the issue of water transport and loss.

“He started looking at water loss, water breakages, and water scarcities, and the fact that we were losing 20% of the water which was distributed on the network,” Guiderdoni said. “He said, that’s insane, there’s got to be a solution to help utilities, and he realized that they were doing a lot of renewal blind, basically.”

Companies in France were just pulling up pipes because they were old, in some cases discovering they were actually in good condition.

“They were saying, that pipe is 100 years old, it should probably be renewed,” Guiderdoni said. “Sometimes they were pulling out of the ground extremely good quality…pipes, and replacing them, and that is actually a really expensive activity, which he said costs between $200,000 to $800,000 per kilometer.

MINIMAL DISRUPTION

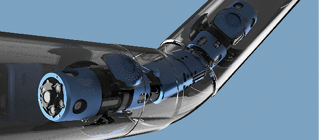

Enter the Clean Water Pathfinder. The robot could be inserted at a pipe access point, then would make its way inside the pipe using flipper-like robotic arms to stabilize it while it moved in a caterpillar-like motion.

“The principle was to build something that creates minimal disruption inside the pipe, because we are running while the water is in operation. The water needs to still flow inside the pipe. It cannot be rolling in the pipe because you’d be moving everything around, and its clean water,” Guiderdoni said.

The robot is jointed so it can follow a pipe up to a 90-degree angle. The one on display at CES is the smallest model, adapted for pipes of 200 to 400 millimeters. A larger version could tackle pipes of 400mm to 600mm, and the largest planned size could inspect pipes up to 800mm to 1,000mm.

The Pathfinder is battery powered, and “it’s surprisingly low on consumption. We built everything around the machine to make sure we are minimizing the battery consumption and extending the life of the robot,” Guiderdoni said.

The company plans to put docking stations at pipe access points so the robot could conduct inspection runs of up to 10 kilometers. Down the line, he said, the company would like to add an embedded charging system to use the motion of the passing water to recharge the batteries.

The Pathfinder on display at CES is what Guiderdoni called an MVP, or most viable product, not a prototype but not a production model. The company will be conducting paid pilot missions with it this year with an eye to entering production in late 2023 or early 2024. The 10 largest private utilities in France have already asked for missions, he said, and a Canadian utility has also expressed interest.

“What is really being developed in 2023 is all the elements around the robot—how you put it inside the pipe, how you can salvage it if there is an issue with the machine, and improving the data collection.”

The sensors the Pathfinder will carry are still in flux. It will have cameras to spot microcracks, internal corrosion and joint issues, but Guiderdoni said it will also need to measure pipe thickness, which would require ultrasound or magnetic flux leakage (MFL) sensors.

“Currently, we are integrating ultrasound, and we will be looking at MFL and other technologies after that,” he said. It will also likely carry audio sensors to detect leaks, which create specific sounds, and some potential customers have asked that it include water quality sensors. The company won’t develop its own sensors, but will integrate commercial ones into the robot.

The first market aim is for utilities providing drinking water, but industrial companies such as refineries have water pipes as well, for needs such as firefighting, and Guiderdoni said they could be future customers.

The company doesn’t plan to work with utilities directly, but instead provide the robot to utility service providers to do the work.

“We want to focus on technology” and continue developing the Pathfinder to do more than just inspect, Guiderdoni said. “In 10 years, maybe we’ll be inside, repairing pipes.”