As more drones take to the skies over construction sites, they’re starting to carry advanced technologies, like LiDAR, to provide even better, more detailed insights.

As more drones take to the skies over construction sites, they’re starting to carry advanced technologies, like LiDAR, to provide even better, more detailed insights.

While most construction leaders deploying drones can get what they need from videos and products created from high-resolution RGB images, some are starting to see the benefits of adding more advanced payloads to their systems – especially LiDAR.

Pre-construction survey, volumetric measurement, topographic mapping and progress tracking are among the UAS applications the industry is embracing. Construction managers and surveyors are impressed with the level of accuracy and detail photogrammetry provides, but also know there are other solutions, like LiDAR, that can give them a more precise picture of their sites. They’re familiar with terrestrial LiDAR and likely have been using it for years, and are intrigued by what LiDAR can do when put in the air.

Chicago-based construction firm CLAYCO recently began experimenting with LiDAR-mounted drones, and while the results are preliminary, Vice President of Virtual Design and Construction Tomislav Žigo can see why it might be worth making the upgrade.

“It’s a quantum change from what we did before,” he said. “Accuracy from a RGB camera varies from between plus or minus two to 10 centimeters. With LiDAR, we’re trying to close that gap and get accuracy that is almost sub-centimeter.”

THE BENEFITS OF LiDAR

LiDAR offers more detail than traditional photogrammetry, providing three-dimensional representations of construction sites and making it possible to see through vegetation.

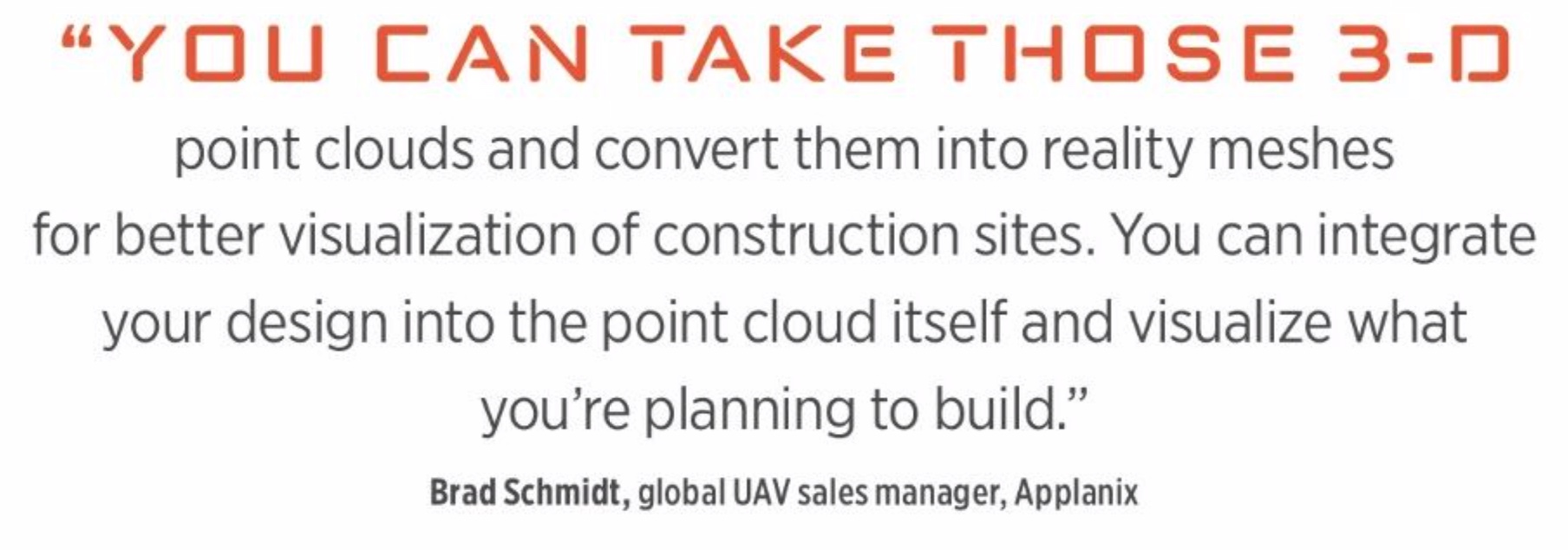

“You can take those 3-D point clouds and convert them into reality meshes for better visualization of construction sites,” said Brad Schmidt, global UAV sales manager for Richmond Hill, Ontario-based Applanix. “You can integrate your design into the point cloud itself and visualize what you’re planning to build.”

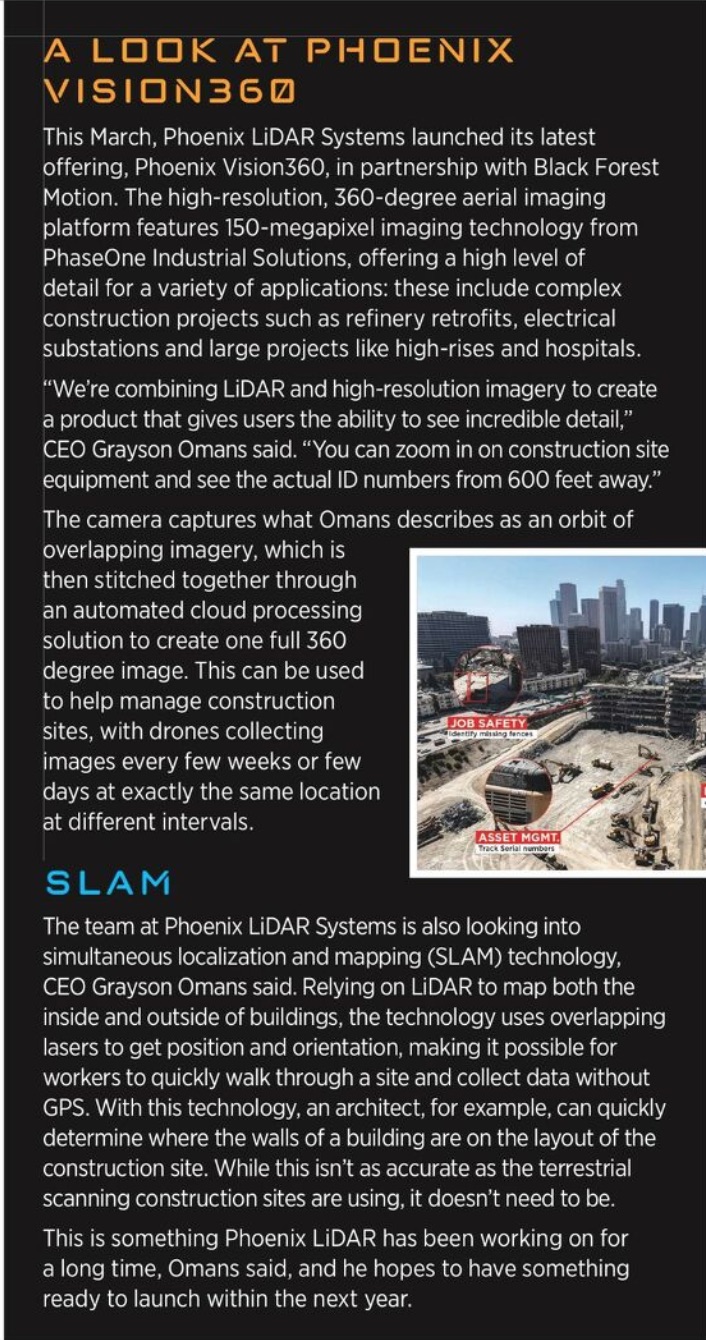

LiDAR is an active versus a passive light source that can pick up even the smallest details, from every high beam on a site to every stud, said Grayson Omans, CEO of the LA-based Phoenix LiDAR Systems. LiDAR is a great solution for more complex projects and has the ability to pick up details and create accurate 3-D models that traditional photogrammetry just can’t, with accuracy in the 1 to 3 cm range.

Aerial and terrestrial LiDARs can be combined for improved efficiencies, he said, and the enhanced level of detail the technology offers can help improve communication on a work site.

Flying LiDAR to create a 3-D model before beginning construction provides advantages, said Matt Rosenbalm, Microdrones sales manager for the southern U.S. It can tell workers how much dirt needs to be moved on a site before they get started, for example, enabling them to bring the right amount of resources to the job.

“LiDAR has the ability to penetrate through multiple layers, such as a tree canopy, to see all the way to the ground,” said Rick Rayhel, Microdrones sales manager for the western United States.

“In traditional photogrammetry where you’re using a camera sensor, vegetation is the worst enemy because you can’t get an accurate representation of what the ground topography looks like.”

ACCURACY ADVANTAGES AND CHALLENGES

LiDAR is starting to gain interest in the industry, but the drones carrying it must also have the proper technology on board for it to provide the benefits users expect.

How can this accuracy be achieved? With differential GNSS systems and inertial measurement units (IMUs), Schmidt said. These solutions are integrated onto UAS platforms and provide direct georefencing of sensor data. Meshing the technologies makes it possible to capture accurate positioning and exterior orientation, which is essential when using a solution like LiDAR. That data can then be accurately georeferenced to the ground, without the need to collect any ground control points or rely on the aerial triangulation technique used in traditional photogrammetry.

“Without orientation the point cloud looks like fireworks,” Omans said. “You need position and orientation, so the IMU is an essential component to building a very accurate 3-D point cloud.”

Microdrones systems, including the mdLiDAR1000, use Applanix products to provide direct georeferencing, Rayhel said.

“Usually, you just get positioning with GPS, then you have to solve for aerial orientation,” he said. “This technology gives you the exterior orientation, eliminating the need for ground control because you’re not using aerial triangulation to get position and orientation. This reduces the time needed to set up ground control points, and it reduces the need for side lap so you’re taking fewer photos, which means shorter flights. You’re also post-processing less data, so you’re saving time in various stages of the workflow.”

Positioning and attitude are of prime importance when you introduce LiDAR into the mix, said Neil Gerein, director product management for Canada-based NovAtel. NovAtel’s SPAN GNSS Inertial Navigation Systems provide both, and are scalable depending on the mission’s requirements. The systems work with different manufacturer’s IMUs, making them flexible solutions for both small and large LiDAR-carrying systems, whether it’s a drone or an unmanned ground vehicle.

On a drone, it’s important to find a solution that provides accurate pitch, roll and yaw, which gives users the LiDAR’s orientation.

“LiDAR is all about sending out a laser pulse, getting a reflection and telling the distance to something from the time the laser pulse leaves,” Gerein said. “As a drone tilts and flies around the corner, or the platform changes orientation because of wind or because something’s in the flight path, you need to know the direction the LiDAR is pointing. That will change the length the light needs to travel.”

NovAtel also offers a dual antenna input system for both airborne and ground applications, Gerein said. This technology makes it possible to get quick alignment of the inertial solution, using GNSS to determine the initial heading. Less precise systems take longer to tell you which direction you’re facing, and that means the need for kinematic alignment.

Any time you’re using a positioning system, signal availability can be a challenge, Gerein said.

“You might not have a direct view of satellites because of buildings and machinery,” he said. “It’s also a very high multipath environment, and you typically need a high performance receiver to operate in a multipath environment. The receiver can mitigate multipath as well as bridge gaps in GPS when there isn’t a clear view of the sky.”

Because the NovAtel solution is tightly coupled, it still provides good performance when full GNSS isn’t available. It also can reacquire the GNSS signal faster if there is a complete outage.

Easy post-processing is also important with these solutions, Schmidt said. Applanix post-processing software, POSPac, offers survey grade accuracy.

NovAtel’s post-processing solution, Waypoint, uses corrections from the company’s TerraStar corrections service and can provide updated corrections on clock and orbit errors in near real time, Gerein said.

LIDAR’S CONSTRUCTION BENEFITS

While the level of accuracy required depends on the application, it’s paramount for many missions flown in the construction industry, Schmidt said. GNSS/IMU integration with LiDAR helps in this area, giving users accuracy down to the centimeter level.

“They’re using this data to position structures and to survey in where different utilities might go,” Schmidt said. “The more accurate the data is, the fewer issues they’re going to run into on the field when they start to construct whatever it is they’re building.”

During the pre-construction phase, LiDAR can provide detailed information on how much dirt has to be moved and how much vegetation is involved, Omans said. During the project, more accurate information can help managers avoid the domino effect errors have on a site once they start to accumulate—not to mention the expense. In the construction industry, accuracy is directly related to cost.

“When it comes to people moving dirt, if they’re off a couple tenths over 100 acres that can be thousands of cubic yards of material. If they’re inaccurate by half a foot, that can be millions of dollars, not to mention the time wasted in having to haul that material off the site,” Rosenbalm said. “If construction companies are left with excess material they have to find somewhere to move that material. It can bankrupt a company if they’re off by a lot, so accuracy is extremely important.”

WHERE IT’S ALL GOING

While RGB cameras and LiDAR seem to offer the most benefits for the construction industry, thermal and infrared sensors also have their place, and can detect hot and cold spots that identify leaks and other problems. Construction companies will begin to use different sensors for different aspects of their work, Schmidt said. They might fly an RGB camera for initial elevation model generation, LiDAR for 3-D modeling and a thermal sensor to check for hot or cold spots.

As far as LiDAR is concerned, as prices continue to come down and capabilities improve, more construction companies, like CLAYCO, will feel comfortable integrating the technology into their UAS. While the firm is still exploring the technology, Žigo sees it becoming an important part of what drones can provide moving forward.

“It’s an evolving technology. Mission planning software is becoming more robust and drones are becoming more sophisticated in terms of their ability to avoid obstacles and maintain a certain altitude,” he said. “We’ve seen huge progress in the quality of data being obtained from drones. In the next two or three years we might get to a point where a gap is closed on the accuracy of laser scanning using drones, potentially enabling us to do more quality control work to verify the accuracy or placement of building elements.”

Drones are changing the way the construction industry manages sites, providing more detailed information more often. And airborne LiDAR is enabling construction leaders to gain even more benefits from this emerging technology.