Advancements across batteries, solar and hydrogen fuel cells are leading to increased endurance and improved sustainability.

While drones are becoming common tools across a broad spectrum of industries, there are still challenges keeping the technology from meeting its full potential. One of the biggest? Endurance.

Current battery technology only allows for about 20 to 30 minutes of flight time. While that might be sufficient for some use cases, it isn’t for most. It’s a pain point limiting both commercial and military operators, and one that will turn into an even bigger obstacle once BVLOS flights become the norm.

That’s not to say there hasn’t been progress made already. Batteries certainly have evolved over the years, particularly their energy density, and they are the source of power for 95% of commercial drones, according to research and consulting firm Fact.MR. They’ll continue to improve, with new chemistries eventually offering better energy density and higher voltages.

Of course, batteries aren’t the only option. There’s plenty of work being done to develop advanced charging solutions and alternative power sources, with hydrogen fuel cells and solar/battery configurations among them. They all have their pros and cons, but the goal with any power solution is to provide users with the most efficient systems possible. That in turn enables them to “steer their operations in an inexpensive way and to get all the benefits out of using a drone,” said Jason Hardy-Smith, vice president of product for Iris Automation, the San Francisco-based company behind the Casia detect and avoid system.

“Power enables or limits everything we do,” said Phil Robinson, senior director, advanced technologies, of Phoenix-headquartered Honeywell Aerospace. “We can have all the communications and sense and avoid we need for BVLOS, but if we don’t have enough flight time to get the drone beyond visual line of sight, it doesn’t matter. We need that power to fly, to communicate and to carry our payloads, and we need to do it safely and cost effectively.”

Another benefit of the research being done around power? Many of the advancements positively impact the environment, whether it’s by reducing the number of batteries needed for a mission or decreasing emissions coming from the drone. Great strides are being made in both sustainability and endurance, improving drone efficiencies and making more applications possible.

BATTERIES

The Rise of the LiPo Battery

Early on in drone development, batteries were an afterthought. Manufacturers typically relied on simple batteries to operate the system and additional connectors to run the camera, Fact.MR Senior Research Consultant Shambhu Nath Jha explained. As battery technology advanced and operators indicated a need for more flight time, that changed. It became clear drone batteries should have a variety of features, including high discharge rates and a high energy-to-weight ratio.

Most batteries used to power commercial drones are lithium ion (Li-ion), with lithium polymer (LiPo) the most popular, Jha said.

What makes these batteries so attractive? Their high energy density and power-to-weight ratio, Jha said. And unlike Li-Ion batteries, they offer safety from explosion.

Not a Perfect Solution

While LiPo batteries have more circuit protection options available, Jha said, they are still prone to overcharging and over-discharging, which can hurt the drone’s performance and even lead to fires.

electroVolt, a company in Rathdrum, Idaho, that develops application-specific lithium-ion batteries and modules, has addressed this issue with its PRISLogic Lithium-Iron Phosphate (LiFePO4) batteries. LiFePO4 cells are less prone to thermal runaway associated with overcharge and lithium plating. The company’s proprietary Thermal Shield Technology offers another layer of protection, improving thermal management, providing distributed pressure on the electrode surface and reducing cell-to-cell fire propagation.

Battery manufacturers are also starting to spend more time on battery management system (BMS) chips, said Matt Carlson, vice president of business development for WiBotic, a Seattle-based company focused on wireless charging solutions. These systems help ensure batteries are properly charged, among other things, again reducing the risk of fire. This improves safety and extends the battery life—a boost to sustainability.

The Future

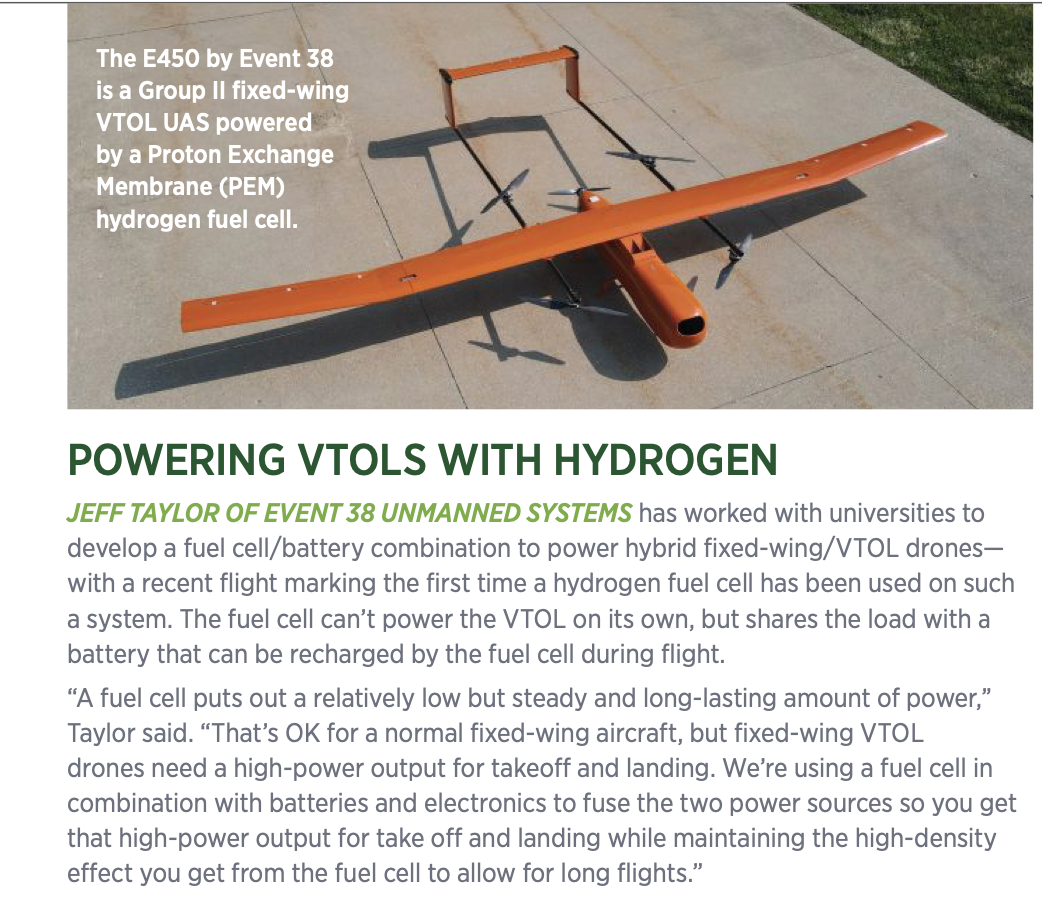

There’s been a steady increase in battery energy density over the last 10 years, said Jeff Taylor, founder of Event 38 Unmanned Systems, in Richfield, Ohio, with new chemistries helping to improve flight time. These chemistries have changed what’s possible, and it’s only expected to get better.

Over time, different LiPo variations have been introduced, with nickel-manganese cobalt (NMC)-based LiPo batteries the go-to option for drones designed to fly long missions and LFP (Lithium Iron Phosphate)-based Li-Po cells well suited for short missions, Jha said. Li-air and Li-SOCl2 batteries, which account for “nearly seven times and two times higher value of energy density than LiPo batteries,” are emerging, but input cost is keeping them from really taking off. Jha expects lithium sulfur batteries to do well in the future because of their reduced cost and comparatively high energy density.

“The battery manufacturers are focused on tweaking the chemistry,” WiBotic CEO Ben Waters said, “maybe adding magnesium or cobalt, to maximize the energy the battery can hold and discharge.”

CHARGING

Wireless Pads Reliably Extend Battery Life

Keeping batteries charged throughout a mission is another power challenge drone operators face. To get around it, most bring extra battery packs to the field, swapping out batteries as needed—which is often. Not only is this a problem logistically, it’s also expensive. Batteries can take hours to charge, and many drones require more than one, so operators must keep multiple fresh battery packs on hand to get them through longer missions. This also makes it difficult to scale, as adding more drones to the mission requires more batteries and more time spent swapping them out.

Wireless charging stations address this pain point, with the WiBotic power pad able to charge a large quadcopter in less than an hour, Waters said.

Many of the batteries used today don’t have the intelligence to tell operators how much capacity is left in them, Carlson said, which could lead to more batteries being used than necessary—a sustainability issue.

“With our software you can track every charge cycle for every battery and get information on how the battery is performing and accepting charge,” Waters said, noting it also provides updates on charging locations and availability. “When you have 20 batteries in the field, it’s easy to lose track of which is your new battery, and which one has 150 charge cycles. So, people throw batteries away before they should or use them longer than they should—which could lead to a fire or the drone falling out of the sky.”

The pads also regulate the charging process, Carlson said, which in turn extends the battery’s lifespan. If a drone is only needed for a 15-minute flight, the pad can charge it to 80%. This avoids the damage that comes with fully charging, again limiting the need to buy new batteries.

Ultrafast Charging

Early in 2021, Israel’s StoreDot demonstrated ultrafast charging in drones—a feat once considered impossible, CEO Doron Myersdorf said. With this technology, the battery receives a full charge in 5 minutes. How? By replacing the graphite, which is not designed for fast charging, in the lithium-ion battery with silicon to eliminate the explosion risk.

With this process, the drone autonomously enters a pod for a charge and is ready to get back to work within minutes, without human intervention. Fewer batteries and drones are needed to complete a mission, another nod toward sustainability.

Common Infrastructure a Need

Interoperability is becoming a theme in charging, Carlson said, making it important for charging stations to be battery-agnostic. For instance, a soldier may need five different drones, each with its own unique battery. Carrying five battery chargers isn’t feasible, making it key for the units to share common infrastructure such as charging pods. The same could be true for a commercial user who needs to capture different types of data using various drones.

“If drones could send a message when they have 5 minutes of charge left that they’re looking for nearby charging stations,” Carlson said, “and the infrastructure responds with, ‘I’m over here come charge on me,’ that doubles the capacity of the drone fleet whether it’s making deliveries or doing bridge inspections.”

HYDROGEN FUEL CELLS

Hydrogen Gaining Steam

Hydrogen fuel cells are starting to garner more attention in the drone world, and it’s easy to see why. Not only do they provide greater endurance than batteries—offering flight durations that are three to five times longer—they’re also zero-emission, Intelligent Energy Aerospace Business Development Manager Jonathan Douglas-Smith said, making them more environmentally friendly than the small combustion engines also used to power drones.

Another advantage over engines? Fuel cells require less maintenance, Event 38’s Taylor said, going for more than 1,000 hours before they need major overhauls. A gas engine demands that kind of attention in as little as 25 hours.

Hydrogen ranks as one of the most “energy dense fuels on the planet,” weighing basically nothing, a key advantage over batteries, Douglas-Smith said. Its cells also last longer than traditional LiPo batteries and only take minutes to refuel, rather than hours to recharge. This reduces time spent in the field and eliminates the need to bring a generator.

Sourcing hydrogen, however, can be difficult, Douglas-Smith said. Intelligent Energy is working to develop a supply chain network to overcome that challenge. Partners in the network will deliver hydrogen cylinders within 72 hours after an order is placed, removing that barrier.

People also aren’t as comfortable working with hydrogen cylinders as they are with swapping out batteries or filling a tank with gas, said Robinson of Honeywell, a company that recently introduced BVLOS UAS technologies that feature hydrogen fuel cells. The cylinders are too heavy to fly, so the hydrogen must be transferred to a lightweight carbon fiber flight tank. Honeywell is working to make this simpler through a tank exchange model, with tanks delivered to operators ready to go.

How it Works

When hydrogen is combined with oxygen, it produces the electricity that powers UAS, said Soonsuk (Fran) Roh, manager of Americas and Oceania business development at Doosan Mobility Innovation (DMI), a company that’s created a hydrogen fuel cell system for drones. DMI recently partnered with Iris Automation to leverage the detect and avoid Casia technology for BVLOS flights.

DMI’s solution doesn’t rely on hydrogen alone, however. It has a small LiPo battery that supports the fuel cell system, say to follow a sudden load change during takeoff or when there’s a gust of wind. The battery might also come into play during an emergency landing.

Intelligent Energy offers a similar configuration.

“The battery provides peak power to the drone when necessary,” Douglas-Smith said. “A battery has a high specific power density, where as a fuel cell has a low specific power density. Combining the two technologies gives us the best of both worlds. The battery will always be able to provide a secondary power source to the UAV, offering that extra layer of redundancy.”

The Sustainability Factor

Producing electricity from hydrogen is a chemical reaction, Roh said, so there’s no combustible process in the system creating emissions. Drones powered by hydrogen aren’t burning gasoline or diesel like other engines, giving them extended flight time without polluting the environment.

Hydrogen is “basically as green as it comes” at the point of use, Douglas-Smith said, with water its only byproduct. The only environmental downside is how hydrogen is created. The most used hydrogen, known as gray hydrogen, is made from petroleum, Robinson said, and produces “considerable carbon impact” when it’s produced. Honeywell is working to expand what’s known as blue hydrogen production. In this process, hydrogen is extracted from natural gas “in a way that lends itself to carbon sequestration.” Carbon is captured at the point of production and stored.

The goal, however, is to get to green hydrogen, Robinson said, which is created through the electrolysis of water using excess solar and wind energy—making it completely green. Solar or wind splits water into hydrogen and oxygen, which then can be bottled and used.

“There are companies scaling right now and growing into the production of green hydrogen, but it requires investing in electrolyzers,” Douglas-Smith said. “Gray hydrogen can be created using existing infrastructure in natural gas plants, so it’s easier and cheaper to create because the infrastructure already exists.”

In Washington state, the Douglas County PUD is producing green hydrogen by electrolysis, said Jacob Leachman, associate professor in the School of Mechanical & Materials Engineering at Washington State University. Installing the electrolyzer made sense because it “so substantially reduced the wear and tear on their dam turbines.” The reduced maintenance costs basically paid for the entire electrolyzer, and now they’re looking to expand the electrolyzer because of “how valuable the hydrogen is compared to electricity.”

Hydrogen also reduces battery use and its impact on the environment. A typical drone battery is discarded after 200 to 300 flights, and only 5% are recycled, Robinson said.

Applications

Hydrogen fuel cell powered drones can take on various applications, from border patrol to maritime security to wildlife monitoring, Taylor said. They offer the longer flight times needed to complete these missions as well as the quieter operation that isn’t possible with combustible engines.

Intelligent Energy customers are carrying heavy payloads like LiDAR and radar scanners for missions, Douglas-Smith said. The Danish government, for example, contracted the company to fly a ground penetrating radar scanner to identify underground peat, which is a large source of CO2 emissions when it’s turned up during harvesting. If farmers know about it ahead of time, they can treat the land to prevent emissions. The project will require the drone to scan 100,000 acres of land carrying a payload weighing about 7 kilograms, making the extra flight time the hydrogen fuel cells provide critical.

Soon, Douglas-Smith sees hydrogen fuel cells being used in drone-in-a-box solutions that are beneficial for linear inspections. Instead of drones charging in the boxes, their hydrogen cylinders will be automatically swapped out, with fewer boxes needing to be set up because the drones can travel farther.

SOLAR

Soak up the Sun

Some use cases require days or even months of endurance, and solar/electric powered systems can provide it.

The team at Toronto’s Superwake, for example, is developing a sUAS that has already demonstrated an endurance time of 18 hours, co-founder Travis Krebs said. The next time it flies the goal is to keep it in the air for 55 days.

The aircraft has a 3-meter wingspan and weighs 13.5 kilograms. There are 4.5 kilos of batteries stored in the wing, which can power the plane for about 10 hours, Krebs said. The lightweight solar array is connected to a charge controller that manages how the power is distributed between the batteries, motors and avionics. In ideal conditions, the solar array can draw in 300 watts. The plane only spends 100 to 120 watts to stay in the air, so the batteries charge at a fast rate. Solar powers the plane during the day, and the batteries take over at night.

There are six packs of batteries on the UAS, with 15 cells per pack. A battery-monitoring circuit onboard the plane sends cell voltages back to the ground so users always know the state of charge. It also monitors temperatures.

The aircraft is designed around the solar array, Krebs said, with the wing maximized to fit as much solar as possible. It also flies slower than most drones, and must be angled properly so the sun actually hits the array.

“You can’t just put solar cells on a drone and see multi-day endurance,” he said. “It comes down to how the aircraft is designed, how it flies and how much weight it’s carrying. You need an aircraft design that’s purpose-built to carry solar.”

The Next Level

High-altitude long-endurance (HALE) aircraft like the PHASA-35, developed from a collaboration between BAE Systems and British tech SME Prismatic Ltd, take endurance even further, providing persistent loitering over one location for months.

The PHASA-35 is designed to stay in the stratosphere, at about 60,000 feet, where weather isn’t a concern and the system is powered by the sun, making it a sustainable option, Head of Business Development Phil Varty said. And instead of having to come back for fuel every few days like other systems, it is refueled by the sun and rechargeable batteries.

The lightweight aircraft, which looks like a glider, is made of carbon fiber composite and has a 35-meter wingspan. Thousands of mobile phone-type batteries are assembled together in small groups within the engine pods. This minimizes the need for wires to connect the batteries, creating the least amount of mass, Varty said, which is critical for a system that aims to stay airborne for months.

And of course, the batteries must be reliable, so rather than drawing on the latest technologies that aren’t completely understood yet, the PHASA-35 team opted for off the shelf mature batteries that are available in large quantities. The solar cells used to charge the batteries, on the other hand, are top of the line. It’s key for the aircraft to get the highest solar power possible, and that’s what these provide.

Environmentally Focused Applications

In terms of sustainability, solar-powered aircraft don’t give off greenhouse gas emissions, including in the manufacturing process, Krebs said. And Varty noted that because they’re staying in the air for long periods of time, it avoids the need to create significant ground infrastructure required for refuelling or to deal with the maintenance issues.

There’s also another environmental benefit, though indirect. Long-endurance aircrafts can take ecological and conservation-focused missions that other UAS can’t.

For example, Krebs said, such aircraft can be used to identify and detect forest fires early, preventing them from emitting CO2 into the atmosphere.

“The system gives us the ability to watch something minute by minute and predict what will happen for things like pollution control and forest fires,” Varty said. “You can then put people and resources where they need to be at the right time.”

Moving Forward

While the power challenge isn’t going away anytime soon, there’s plenty of research and product development being done to address it. The options will only continue to grow as we move into the next commercial drone phase, which will include routine BVLOS flights. Sustainability will also continue to be a focus, with greener solutions moving to reduce concerns such as fossil fuel emissions and improper battery disposal.

“When new technology comes out there’s always a rush to deploy it; then shortly thereafter there’s this need to optimize it,” Waters of WiBotic said. “We’re coming up on the need to optimize. What people are doing with drones is providing tremendous value, but now that we’re using the technology regularly we have to find ways to save money and do it more efficiently.”