When it comes to selecting the optimal IMU for autonomous devices and other tactical- and navigation-grade applications, performance is paramount—and usually comes at a price. Fiber optic gyroscopes (FOG) and ring laser gyroscopes (RLG) have long been the go-to solutions for the best performance in these demanding conditions. Then along came tactical silicon and quartz micro-electro mechanical systems (MEMS) gyros and accelerometers.

Comparing performance under nominal laboratory conditions poorly predict real-world realities which likely include temperature changes, vibration and shock which result in significant and sometimes unpredictable error rates that are difficult to model.

Several studies have been done in recent years to evaluate the performance of MEMS IMUs with comparative legacy FOG and RLG systems as general purpose tactical grade solutions—with some surprising, to some, results.

PERFORMANCE COMPARISON

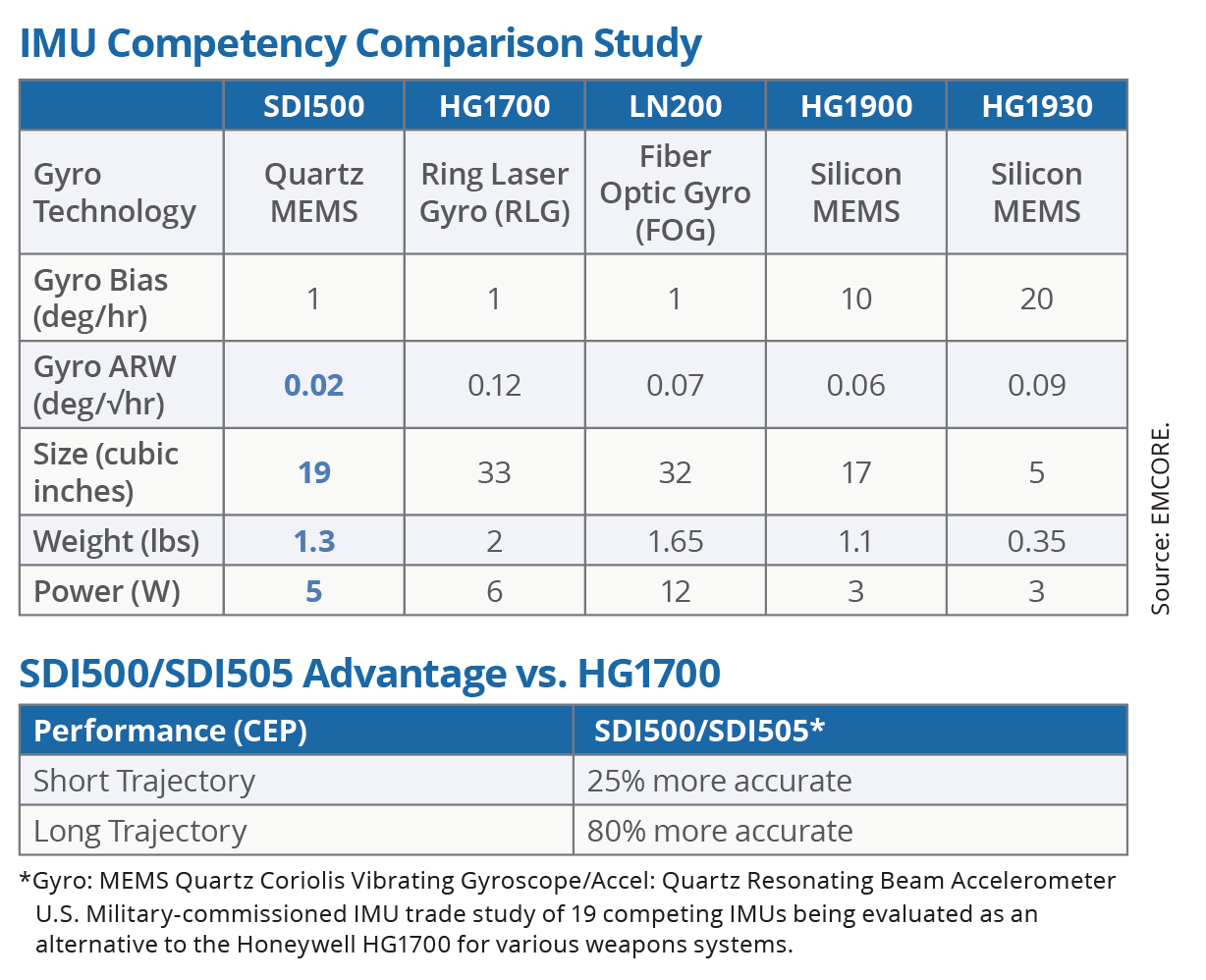

A baseline IMU competency study in 2018/2019, funded by Systron Donner Inertial (SDI), compared RLG, FOG, SiMEMS and QMEMS IMU performance in laboratory and environmental conditions. Internal results concluded the SDI500-AE10 tactical grade QMEMS IMU had the lowest level of integrated error despite being smaller, lighter and lower power than its direct competitors.

Optical (RLG/FOG) IMUs in common use in legacy systems were the closest in performance to the SDI500-AE10—though they exhibited larger errors under stress. Silicon MEMs and low-cost FOG sensors exhibited significantly greater error levels.

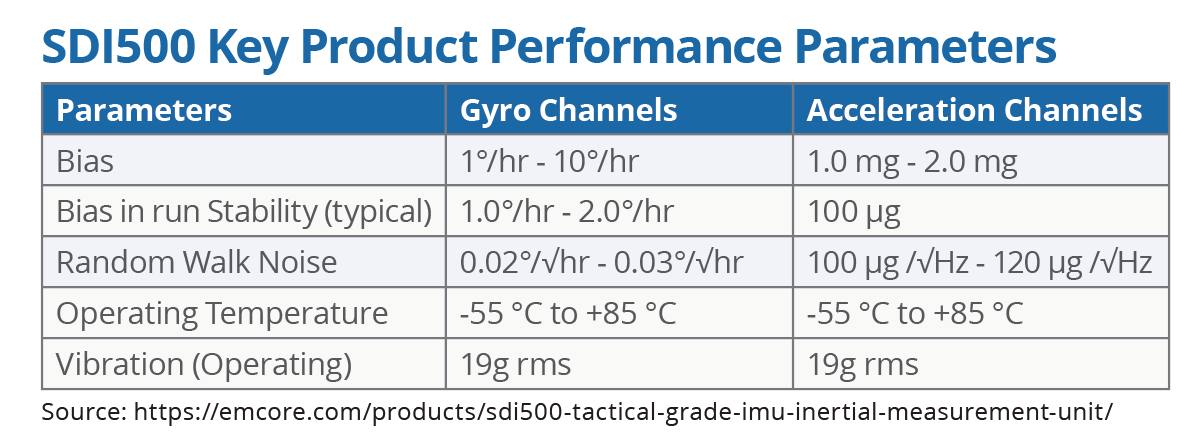

QMEMS IMU offered the best overall performance level by consistently achieving best or comparable performance across environmental conditions, including extended temperature range (-55°C to 85°C) and captive carry conditions. Other IMU solutions have strengths in specific areas but fall short compared to QMEMS in terms of integrated error.

A recent U.S. DOD independent 3rd party IMU study (Feb-March 2021) has helped better compare and contrast some of the industry’s top solutions. 19 IMUs of various technologies, complexity, cost, and developmental status, from leading manufacturers, were evaluated in short and long flyout simulations against the HG1700.

The dual-use non-ITAR SDI500/505 IMUs are designed to achieve the demanding performance levels required in sophisticated systems, including weapons guidance and targeting, commercial and defense fixed-wing aircraft and helicopters, unmanned autonomous vehicles (UAVs), and a wide variety of other high-precision commercial, industrial, marine, defense and space applications. They leverage quartz MEMS technology to deliver angle random walk (ARW) values of 0.02°/√hr with 1°/hr bias stability. The study evaluated 19 competing IMUs as a suitable replacement for the Honeywell HG1700 IMU, which is used in various weapons systems.

Every IMU was tested versus two munition trajectories:

• Short trajectory: 54-second drop

• Long trajectory: 346 seconds of straight and level flying followed by 54-second drop

Further, the mechanized Δv and Δθ values including the position, velocity, and attitude misalignment errors at handoff. The evaluation team also calculated the horizontal difference from the truth position to determine the horizontal error.

The following errors were added as simulated measurement errors:

• Accelerometer time correlated bias

• Accelerometer velocity random walk

• Accelerometer scale factor

• Accelerometer misalignments

• Gyroscope time correlated bias

• Gyroscope angular random walk

• Gyroscope scale factor

• Gyroscope misalignments

The study concluded that EMCORE’s SDI500/505 IMU, which features reduced size, weight, and power (SWaP) compared to the HG1700 IMU, delivered “compelling performance, cost, SWAP, maturity” and outperformed the HG1700 in both flyout simulations.

The test house spokesperson stated, “the SDI500/505 system was a solid performer across the performance, technical maturity, warhead integration, and cost analysis threads.”

DUAL USE/HIGH PERFORMANCE

The dual-use non-ITAR SDI500/505 IMUs are designed to achieve the demanding performance levels required for challenging applications such as commercial and defense fixed-wing and rotary UAVs (unmanned aerial vehicles) and robotic platforms. These IMU’s leverage industry-leading Quartz MEMS technology to deliver Angle Random Walk (ARW) values of 0.02°/√hr with 1°/hr bias stability.

Albert Lu, EMCORE Senior Vice President and General Manager of Aerospace & Defense, commented: “The results of this IMU trade study are further validation of the clear industry leadership of our mature and proven SDI500/505 IMU. They outperform other MEMS IMUs and continuously deliver comparable performance to older, costlier optical IMUs in a lower power, smaller, and lighter form factor.”

The SDI500 shows remarkable SF linearity for an open loop MEMS, with performance that even exceeds some of the larger navigation grade systems. As well, the size, weight and power of these systems can be suitable for small satellites if reduced to half SF nonlinearity quadratic coefficients are repeatable enough to be compensated to further reduce SF error.

EMCORE recorded production histograms for the SDI500 between March 2020 and March 2021.

Nine (9) of the performance metrics measured showed over a 20% improvement from calendar year 2019.

DRIVING NEW DIRECTIONS

In 2021, EMCORE introduced a new SDI170 quartz MEMS tactical-grade IMU designed as a form-, fit- and function-compatible replacement for the HG1700-AG58 ring-laser gyroscope (RLG) IMU, but with superior overall performance, versatility and a significantly higher mean time between failures (MTBF) rating over ruggedized environments.

The SDI170 IMU leverages the smaller, low power, rugged and high performance QMEMS inertial sensor assembly from the SDI500 into a larger HG1700 RLG form factor. This IMU is suitable for continuous-use applications with no wear-out components and delivers highly linear accelerometer performance and longer life compared to the HG1700 IMU. It is not ITAR controlled and has completed extensive internal and external customer testing to confirm compatibility to replace legacy products.

The unit is designed for a wide range of high-precision, integrated commercial and defense applications including aircraft Attitude Heading Reference Systems (AHRS), GPS-aided navigation, ground surveying, mobile mapping, ROVs, autonomous vehicles, tactical weapons, and stabilization platforms.

The SDI170 proven FFF has performance advantage over legacy RLG, with higher MTBF, lower noise, lower bias instability. Its performance compatibility was based on both internal and 3rd party customer testing.

One tester noted, “The parameters of SDI170 tested are satisfactory. All the parameters (noise, bias stability and repeatability, scale factor repeatability, misalignment repeatability) are in the range of specification of SDI170.”

Another said, “We found that SDI170’s interfaces are exactly compatible with the HG1700. In our tests, we were able to directly use the previously prepared mechanical interfaces, cabling, and data acquisition software for the HG1700.”

Finally, a third noted, “We are glad to test and work with such a well-designed, high-performance compact IMU.”

As tactical IMUs to serve the defense market, the SDI170 and SDI 500 both offer next generation lighter, smaller platforms with high performance.