Cyberhawk recently completed the first full ABS Intermediate Hull Survey 4 on an oil tanker with a drone.

Inspections were performed across 19 tanks onboard an oil tanker while at a shipyard in Singapore, according to a news release. This included 12 Cargo Oil Tanks (COT), two slop tanks and five ballast tanks.

The American Bureau for Shipping (ABS) was on hand to ensure the quality of the inspection complied with the specific ABS rules (ESP) set for tankers. Because the vessel was American flagged and operated in Alaskan waters, the inspection also had to satisfy the U.S. Coast Guard’s Critical Area Inspection Plan (CAIP).

Typically, workers scaffold the inside of the tank so ABS surveyors can perform a visual survey and NDT technicians can take thickness measurements. This could lead to damage to the tank coating. Other hazards include the potential for dropped objects when lowering the equipment into the tank and working at height in confined spaces.

It takes about seven days to set up and remove the scaffold and to perform the inspection. Cyberhawk was able to complete the inspection in one day with a two-man team.

Rope access is another option for inspecting the tanks, but ABS surveyors would need to be rope access trained or a live feed from the rope access technicians back to an ABS Surveyor on the tank top would be required. This would take three times longer than deploying a drone and require an ABS surveyor to be available.

NDT technicians still had to take thickness readings at accessible levels as part of this inspection to meet ABS survey requirements for this class of vessel. But, Cyberhawk will soon conduct its first proof of concept on a UT solution from drones that would eliminate the need for scaffolding or rope access technicians or rafting solutions.

“Since we conducted the first UAV tank inspection back in 2015, the take up of this solution has become increasingly adopted within the industry,” said Malcolm Connolly, technical director at Cyberhawk, according to the release. “These previous inspections, however, have only focused on capturing visual data of approximately 20 to 30 critical areas. To comply with ABS rules for this particular category of class survey, we required close-up coverage of 100% of the tank’s internal frame structure at a resolution equivalent to a person viewing the surface at arm’s length.”

The team completed more than 350 flights and collected more than 600GB of data, which is hosted on iHawk, Cyberhawk’s cloud-based visual asset management software.

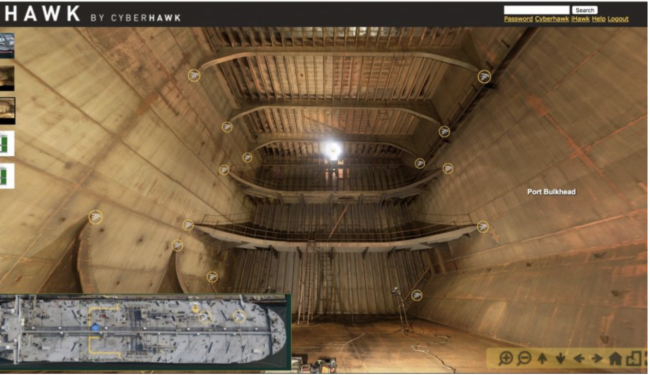

Through the software, the client has a 360-degree view of the inside of the tanks, with defects and areas of interest highlighted. The high definition imagery collected makes it possible to see points of interest in great detail so they can make evidence-based asset management decisions. The client also has a complete visual record of the tank, which can be used to monitor the condition of the tank and the degradation of any defects.

“By hosting data in a cloud-based asset management system, such as iHawk, inspection information can be viewed in a far more intuitive and efficient way compared with wading through a 100-page inspection document,” Cyberhawk CEO Chris Fleming said, according to the release. “This also means that multiple stakeholders can access and view exactly the same data, which also provides a realistic representation of the asset even for those who have never been in contact with it.”