The Swedish heavy equipment manufacturer Scania just fired up the latest member of its autonomous family: Scania AXL, a fully autonomous concept truck, without a cab, designed as a mining loader.

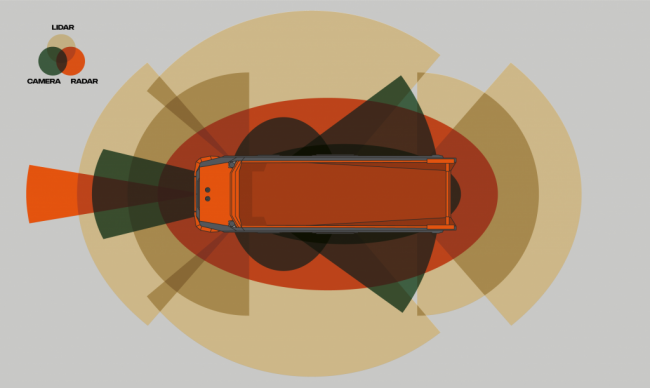

Scania AXL is equipped with cameras, radar, LiDAR and GPS receivers, and is steered and monitored by an intelligent control system. Autonomous operations are facilitated by logistics that tell the vehicle how it should perform. For example, a white line circling the vehicle at its midriff is the human-machine interface, where the machine registers human presence. In this way, personnel can be around it and the truck “knows” they are there and behaves accordingly.

Photos: courtesy of SCANIA.

The system is designed for a level that meets the operational needs of mines, an environment favorable for self-driving pilot projects since they, along with construction sites, are well-controlled locations. “The system isn’t yet street smart but it’s certainly smart enough for being used in mines,” said development engineer Magnus Granström, Autonomous Systems Development. “A mining environment is easy to automate. You can influence the environment so much. We have control over how wide the roads should be. We can say that, oh, we have a messy situation here, we want to avoid that, let’s rebuild it. You can’t do that out in the real world.”

“We already have self-driving trucks in customer operations. However so far, they have been with room for a safety driver who can intervene if necessary. Scania AXL does not have a cab and that changes the game significantly,” said Claes Erixon, Head of Research and Development at Scania.

“The vehicle should behave correctly based on what it sees,” stated Carl Wettergren, design engineer, Layout & Control. “From my side, with hardware, it needs to have the possibility to see. It’s really important how we place the sensors, and that they can back each other up. If, for example, one breaks, another can work in its place.”

“There are three different kinds of sensors throughout the vehicle, and they are all suited for different purposes,” said Jihad Daoud, project manager for Scania AXL. “We have seven camera units. There’s a laser beam that sweeps across the surroundings; the light is reflected and processed. We have radar at the front, the back, and to the sides.”

“An autonomous vehicle has much more to do with software than with hardware,” added Granström. “The software that we have in AXL has been developed for many years in other projects. We’ve had a number of other autonomous projects where we’ve built a software foundation, which contains a number of different building blocks. Which we then, in a modular way, can put together for different applications. This is just one incarnation.”

In another departure from the trucking norm, AXL’s internal combustion engine runs on renewable biofuel.

The first live public demo of Scania AXL will take place on October 2 in Södertälje, Sweden.