Eonix has been awarded $1.7 million by AFWERX (the Air Force’s tech innovation program) to develop specially tailored electrolytes that could enable batteries to achieve higher energy discharge rates needed to deploy directed-energy weapons such as lasers as well as power unmanned aerial systems.

Like customizing gear in a videogame, there are different qualities one can optimize in a battery’s liquid electrolyte. Eonix’s foundational work focused on safety by raising the flashpoint at which a battery combusts too a higher threshold—from a typical 17 to over 150 degrees Celsius. That’s a vital quality for extremely energy dense batteries carried by or alongside personnel into combat situations where a stray bullet or piece of shrapnel could too easily trigger battery combustion.

But now Eonix’s is optimizing for output to meet the voracious demands of energy weapons.

“[Directed energy weapons] need a ton of energy for a short duration,” Eonix CEO Don DeRosa told IUS. And if lasers or microwaves are to effectively take down drones and hypersonic missiles before they can reach their targets—as the Pentagon hopes to do—they require discharge rates “out of this world” he says.

“You’d think that there are high power options available, like ultra capacitors, but even those don’t store enough energy. When you discharge large amounts quickly, that’s going to heat up your battery pack, then you need a lot of cooling, and that increases weight and size. “

The key quality of his company’s electrolytes, DeRosa says, is that they are broadly ‘drop-in’ solutions—tailored in advance to integrate into existing battery cells without modifications to their electrodes and furniture that would entail increased R&D, engineering and production costs for the manufacturer.

The tweaking instead is done by Eonix to the electrolyte, sometimes integrating additional components to optimize the liquid for a given cell type.

“I don’t think you can tackle this with available or even near-term COTS technology. What we’re doing is taking advantage of COTS battery cells and designing electrolyte that will enable them to do the job. I like to think of it as being backwards compatible.”

However DeRosa has more than just lasers on the mind for the new electrolytes. “We’re really designing them to be cross-platform tech, for any high-power applications DOD and consumer market-like E-VTOLS drones.”

For example, the company’s non-flammable lithium-ion battery electrolytes due for commercialization in 6-12 months could be used to improve safety of devices like electric vehicle chargers situated in residential and/or urban areas.

Materials discovery with ATLAS and Schrodinger

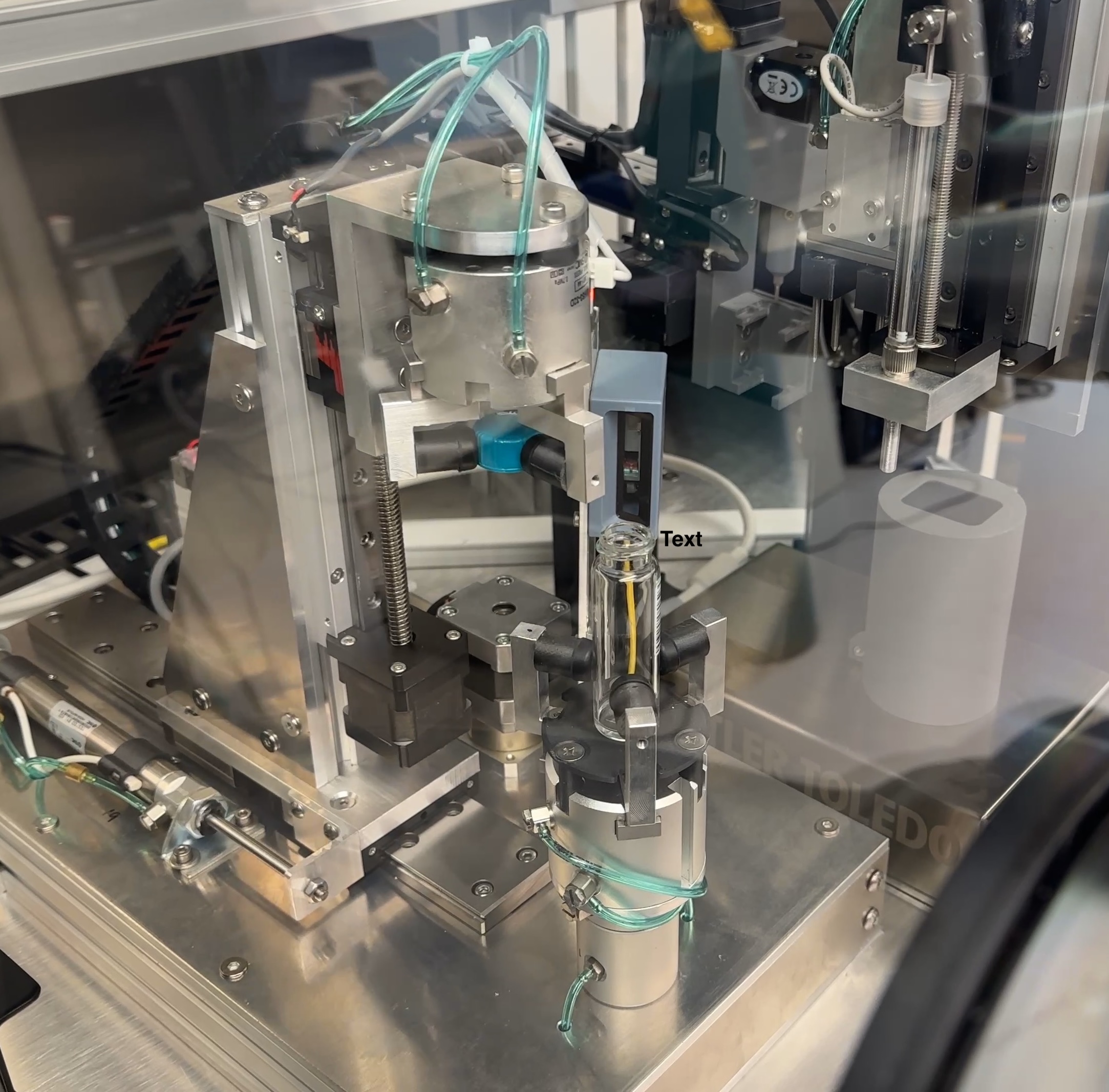

Eonix is able to devise tailored electrolyte electrolytes thanks to a materials discovery tool called ATLAS that allows the company to devise and test new materials at unprecedented speed, figure out what worked or didn’t with a particular formula, and then try again in just a few days.

“When I was getting my PhD, we did two molecules every five years,” DeRosa told me. “Back [when we started] we were able to look at new electrolyte chemistry every eight days. Now, it’s down to three. days”

Of course, there’s still a lot of failing-until-you-succeed involved. “You have to be emotionally strong. It’s important to know that most things won’t work, and it’s exciting to learn that in 3 days and not two years.”

Crucially, it’s not just a trial-and-error numbers game because the data ATLAS collects from failures is detailed enough to improve the process iteratively with each subsequent attempt.

ATLAS’s development was only possible thanks to Eonix passing on the venture capital model in favor of grants from the NSF, and Departments of Energy and Defense. This allowed the company to spend the 3-4 years properly design the various tools, the fastest of which required 9 months.

“We’re on our third custom cycle monitoring tool,” DeRosa told me, “and each one of those takes a really long time. We had to do a lot of design work internally, and you can’t do that the VC route, or even the academic route where you have to publish a paper.”

DeRosa argued that other attempts to train AIs by scraping data from available academic research were flawed because they were fed an unrepresentative sample biased in favor of successful research (the failures often don’t get published) and too much of the data tended towards “novel, bespoke chemistry.”

A somewhat better approach he felt was to conduct lots of testing to generate better data, but often these research methods, he says, yield pass/fail results without insight on to why a particular formula works or doesn’t. ATLAS, by contrast, collected detailed data that allows learning from failures and improve the subsequent efficiency of the discovery process.

Eonix is now incorporating computer vision systems to their discovery process. “There’s a lot of stuff we can do that was very tedious, costly, inaccurate, not very reproducible; but by pairing robotics with vision systems we can automate them and build them fairly cheaply. We’re able to take pretty lightweight vision models and fine tune them to perform analysis and collect data on experiments we’re doing—things like surface tensions are really important, fluid movement, how things disperse and interact with surfaces is of paramount concern. Batteries are rolled up tightly, so understanding capillary action is important.”

For its work connected to high-discharge capacity batteries, in 2022 Eonix also partnered with Schrodinger, Inc., a company specialized in applying machine-learning to materials discovery. According to DeRosa, Schrodinger’s AI product provides suggestions on what formulas to test next as mere humans run dry on ideas.

“We’re trying to run through a hypothesis a lot quicker,” DeRosa explained, “but we’re generating so much data it takes an inhuman effort to generate new hypotheses at the same rate. So we have a set of new algorithms to evaluate new theories at a much quicker rate. If we’re making 32 solutions today and have the results at 5 pm, we’d have to have a scientist review all that data overnight and evaluate lessons learned. And the following day and the following day. And at a certain point that becomes a bottleneck. So we had to involve a computational framework to keep up.”

Sir, I design electrolytes for a living

How does a business like Eonix find its niche not manufacturing the battery module itself, but designing the electrolyte for custom battery cells?

“Business-to-business sales are preferred, because building pathways into government procurement is an arduous process.” He argues their product can become an ‘enabler’ by helping improve safety of promising products that fall short of regulatory standards, say due to using lithium-ion batteries (LIBs) that boast superior energy density, but that are less safe than heavy lead-acid batteries.

“Instead of resorting to antiquated lead-acid battery tech, [by using high-flashpoint electrolyte] you can have performance of an LIB battery with the safety of lead-acid. It’s major hurdle for electronic warfare, E-VTOL aircraft and C-UAS.”

Eonix’s ATLAS-powered materials R&D machine has reportedly interest outside customers as one might expect. However, while Eonix has fruitfully partnered with universities on occasion—particularly University of Tennessee—DeRosa said he’s weary of offering one-time research services in this manner.

“A lot of companies want to pay us money to come in and develop incredibly valuable IP for them. And then they go off and get recurring value from that product. We’re not built for service contracts.” DeRosa says he wants “scalable relationships” selling battery electrolyte to battery-makers, not one-time sales of valuable formulas.

The final frontier: energy density?

Having devised non-flammable and high-output electrolytes, is improved energy density the final frontier for Eonix?

“We haven’t yet because we’d need to work with cell manufacturers to tweak electrodes,” DeRosa said before adding “Not a lot of people have been super creative with electrolytes. So we could go to a higher voltage, say 4.8 volts, to unlock significant gains. Or consider high-density silicon anode-batteries—the big issue is their tendency to expand and crack the interface. So we’ve had a bunch of silicon companies reach out to us to help design an elastic electrode. [Our electrolytes] could unlock potential in higher density silicon anodes, higher voltages, or both.”

As long such new batteries use liquid electrolytes, DeRosa says, Eonix’s electrolytes can enhance them. “Solid-state, we’d have to design new approach,” DeRosa concedes, but he’s bearish on that sector broadly. “You’ll see a lot of the solid-state companies that have gone to hybrid with lithium coating on foil, validating my opinion that what they’re trying to achieve wasn’t necessarily viable. It’s hard to make Lithium to go through a solid and then a liquid, so you have to shrink your distance, and that introduces a lot of quality control and reliability issues. Your problem becomes designing a new way to manufacture reliably at 5 microns instead of 45 microns.”

For now Eonix is aiming for to produce enough electrolytes for 350,000 battery cells each month. That could generate 80 megawatt-hours equivalent of batteries annually—and that just to satisfy “very specific defense and aerospace needs.” Given that allocation, DeRosa explains “we’re looking to scale this commercially in a different way.”