Drawing on its extensive drone delivery experience in Africa, Zipline is working to expand its delivery services around the world.

Zipline’s evolution can be painted by numbers, and aspiration.

Since the autonomous logistics company began in March 2014, it has done much to keep one of its brand promises: “changing delivery for good.” To date, its fixed wing all-electric vehicles have flown 40 million miles in seven countries, mostly BVLOS.

In Rwanda, where Zipline deliveries of blood and blood products earned worldwide attention, “Zip” drones have helped reduce wastage by 67% with 88% fewer hospital maternal deaths due to postpartum hemorrhaging as compared with non-drone-use facilities. Globally, Zipline now serves 3,400 hospitals and health care facilities, is contracted to serve more than 10,000, and is rapidly expanding the product roster it delivers.

Flying in both remote and populated areas, Zipline’s delivery system embraces another promise—“the best delivery experience not on Earth”—lowering emissions by up to 97% than traditional ground vehicles. Last year, Zipline entered Asia, flying medical supplies to a remote island chain in Japan, representing the first time the country’s Civil Aviation Bureau approved BVLOS flying without onboard cameras in its busy airspace.

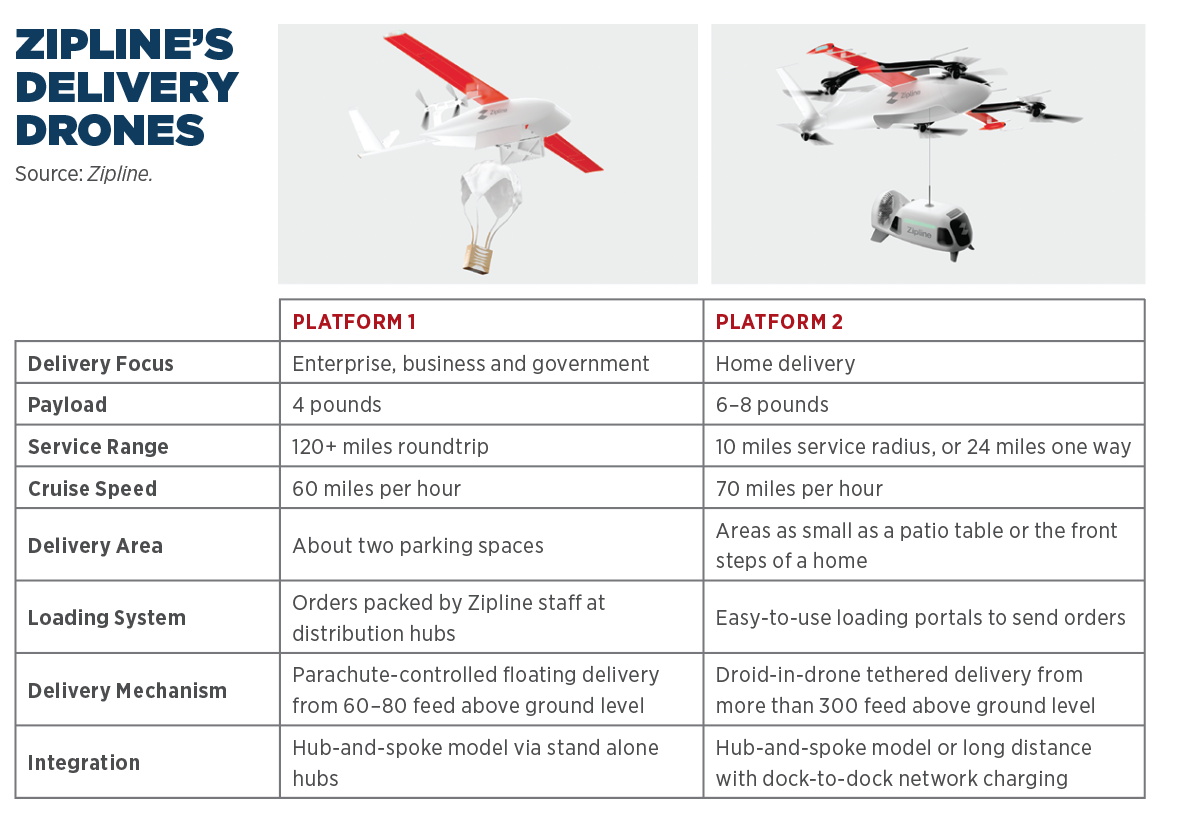

Closer to home, last year Zipline scored the FAA’s Part 135 certification under the agency’s BEYONDinitiative to safely integrate BVLOS drone operations into the National Airspace System. And this March saw the introduction of the Platform 2 Zip, designed to autonomously deliver twice the weight of the original to denser populations, including individual homes. Once again, many delivery locations will be beyond visual view.

“The vast majority of our more than half a million commercial deliveries were BVLOS flights,” Okeoma Moronu, Zipline’s head of global aviation regulatory affairs, told Inside Unmanned Systems. Zipline now claims to be the largest autonomous delivery system on Earth even as it finds appropriate national mixes of range-empowering technology, safety at scale, and engagement with communities and regulators.

RWANDA: RANGE MEETS LOGISTICS

“The first time I saw the Zip fly over the horizon, I got a little heart palpitation. It’s pretty magical, and it took a lot to get that to be robust.”

Keenan Wyrobek, Zipline’s co-founder, CTO and product architect, explained the impetus that led to the South San Francisco-based company’s launch, and later focus on Rwanda. “My wife’s an epidemiologist and co-founder Keller’s [Keller Rinaudo Cliffton] family is in public health. “We were exploring impactful, basic products we wanted to develop, and they were nudging us all the time, saying, ‘We keep hearing about vaccine campaigns and other health initiatives getting stuck on logistics—Go look into that.’

“I’m a massive skeptic,” Wyrobek confessed. “I love exploring things, but I thought I was going to find 1,000 reasons why we really couldn’t do anything. Amazon had already been talking about delivery drones, and we slowly eliminated all those concerns and got conviction that we should go do this.”

In 2016, Rwanda became Zipline’s first customer. Occupying 12,000-plus square miles, the central African country is known as “the land of a thousand hills,” and its north-south mountain range includes the gorilla-famous Virunga Volcanoes. Roads could be difficult, and the skies contain less crewed air traffic than in the U.S. Consequently, Rwanda presented a range and logistics case for creating an airborne delivery model servicing remote areas, one that could save lives while providing BVLOS benchmarks for more developed areas to adapt or go beyond.

“Fundamentally, when you think about delivery, it’s the value of the range,” Wyrobek continued. “We started with blood, which is that canonical use case for on-demand delivery where it has a shelf life way shorter than you imagined. It’s always scarce no matter what country you’re in, so you want to be able to hold it until you know exactly which blood types are needed in which location, so you don’t waste it. You want to serve as much of the country from a few locations as possible. What drove that long range was being able to think of it as operational simplicity.”

Deployment was announced in 2016, with 22 transfusion centers targeted for deliveries by Zips whose range would grow to 120-plus miles roundtrip. With the Rwandan Civil Aviation Authority and national health agencies providing performance-based standards for operational safety, Zip drones flew from “nest” hubs, delivering payloads (now at 4 pounds) into “mailboxes” at their destinations.

The number of flights has risen from an initial five to 10 daily to as many as 1,000 per 24 hours, across the country. And Zipline has expanded its African presence into Ghana, Nigeria, Kenya and the Cote d’Ivoire.

Today, Rwandan President Paul Kagame sees Zipline’s role as “a case in point of transformation, of economic prosperity that changes people’s lives for the better.”

SIMPLICITY MEETS REDUNDANCY

“We were 100% obsessed with making what we now call Platform 1 to be a product that people love,” Wyrobek said. To do that, Zipline faced what he called “the quintessential challenge: “How do you keep it as simple as possible but no simpler? Simplicity gets you reliability and redundancy, and you have to bring those two things together really carefully.”

BVLOS capability was key. “This has been fascinating, creating a really robust BVLOS capability,” Wyrobek said. “When we started, I thought we’d be able to buy a lot more.” Instead, Zipline set out on its own to refine elements from its navigation solution to route planning and online fault handling. Continuous improvement has resulted in seven major generations of the initial Zip.

“How do you architect the avionics and software systems to enable testing across the stack?” Wyrobek asked rhetorically. “It’s not just about the drone itself. It’s also about the cloud, it’s about the servers on the ground, it’s about the radio communication systems, the cell networks.”

Wyrobek noted the Zip itself is just one part of providing crucial BVLOS integrity in the face of terrain, weather and other issues.

“ZipNav is that core navigation capability,” he said. “Our navigation system is redundant at every level—INS systems that are each talking to a diversity of satellite networks, redundant IMUs running on a redundant compute with redundant power. To try to execute that in a very small, light drone was quite interesting. All the logic it takes to actually tell the difference between good error data and bad error data, to detect and handle that without losing your flight margin, there are a lot of interesting subtleties, a phenomenal amount of testing.”

But, he added, navigation is just one of 20 or so tiles that make up the system. Online [software on the vehicle] is part of the detect and avoid capability. At the same time, Wyrobek said, offline route planning comes into play. “It is such a tricky optimization challenge to even find a route that gets there, and if you do that online you don’t have enough compute on the vehicle. So, you have these nominal routes, but the Zips can deviate in response to ADS-B and acoustic information.”

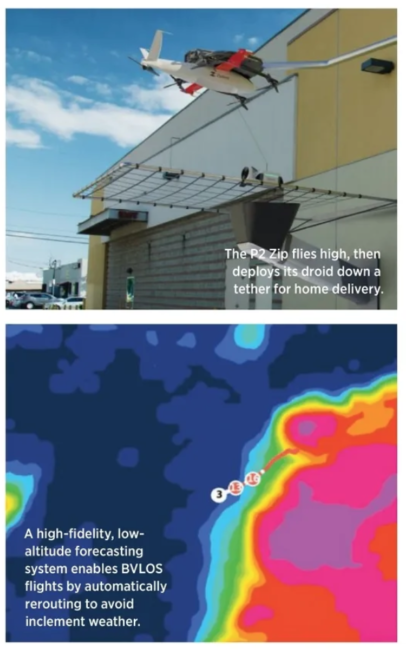

Routes can feature harsh weather, and Wyrobek recalled some agita “the first time I watched a Zip launch and fly into a thunderhead over the horizon, and it came back an hour later, soaking wet, having done a delivery.” Developing a solution wasn’t that simple. “Most of the industry back then had grown up with some form of taking pictures of things,” he said. “We built our own capability that uses our historical flight data as weather stations, for real-time access to satellite imagery. We built an AI model that specifically forecasts about five minutes into the future of each of our Zip’s flightpath the probability of a microburst so strong we can’t fly through it. We can route around it, dramatically reducing the frequency of parachute landings.”

Finally, there are humans in the loop checking, planning and running datasets for terrain and cell towers. “We have what we call our controllers. They can tell us to hold this position, come home, deploy its parachute landing system. We think of them as orchestrating the airspace of our Zips.”

All these solutions support BVLOS safety. “When you’re flying over two mountain ranges to make a delivery, like we do in Rwanda every day, finding a route that respects regulatory requirements and the vehicle’s limits and still closes on that mission, that’s one full set of capabilities. All the systems it takes to redundantly communicate and control these aircraft is another whole world of Zipline technology.”

P2: HOME DELIVERY AND BVLOS

This March, Zipline launched Platform 2, which offers a two-part architecture for on-demand home delivery. The P2 Zip flies high and very quietly to homes, hovering while its droid moves down a tether, steers to a location and leaves a payload of up to 8 pounds on a driveway, patio table or a front step.

P2’s 10-mile autonomous service radius is targeted to metro-area home delivery—“it’s tremendously quiet and unobtrusive,” Wyrobek said, as well as precise per its acoustic and visual sensors. But P2 can fly up to 24 miles one-way without a payload, charging before picking up the next delivery and/or moving further away, so a good part of its flying will be BVLOS. Wyrobek: “The Zipline ethos is to work deeply with customers from the beginning, relying on their data and their feedback through all these design trades. So, with the classic three legs of the trade space—range, payload, cost—it was really clear that you needed that beyond visual line of sight range, even with this metro and home focus.”

Initial U.S. partners for P2 include Michigan Medicine, Intermountain Health of Utah and Washington’s MultiCare Health System. Commerce and food deliveries will expand the roster. Fittingly, the debut customer will be the government of Rwanda. Asked at the P2 announcement press conference if he would allow his house to be an early delivery site, President Kagami said, “Let’s make it the first!”

REGULATORY INTERACTION

Integration into the crowded, crewed legacy skies of the U.S. has required interaction with governmental agencies, especially the FAA. The year 2022 was a banner one for unmanned systems, notching 60% of waivers to date for BVLOS flights with multiple legislation enacted.

• The public-private Integration Pilot Program of 2017 identified nine lead participants to test BVLOS and other solutions. North Carolina Department of Transportation (NCDOT) and Zipline partnered in what Zipline’s Moronu called “a great opportunity to advance our work on enabling our detect and avoid system.”

• In 2020, the federal Partnership for Safety Plan, or PSP, set out “to facilitate the identification and mitigation of hazards at the local level.” This program, Moronu said, has “been a helpful way to advance the safe integration of our technology through existing regulations while simultaneously being part of its evolution. We’ve learned that to scale operations successfully it’s really important to address and leverage things that already exist, like the PSP.”

• In June 2022, the FAA’s BEYOND program continued the work of the sunsetting IPP. Zipline received FAA Part 135 certification, allowing it to operate the longest-range on-demand commercial drone deliveries in the U.S. and cover the largest area by a UAS service provider. This allowed Zipline to fly up to 26-mile roundtrips.

• Most directly relevant to BVLOS is Zipline’s recent role as an industry lead on the FAA’s BVLOS Aviation Rulemaking Committee (ARC), which also in 2022, issued a nearly 400-page report providing recommendations to normalize safe, economically viable and environmentally advantageous UAS BVLOS operations.

“We’re excited to take our learnings from the tens of millions of miles we’ve flown beyond the visual line of sight in other parts of the world and apply them in ways that meet the needs of the local airspace to serve local communities,” Moronu said. Wyrobek concurred: “We operate under many of the same regulations as passenger aircraft, and we’re proud to uphold those strict standards.”

FLYING THE FUTURE

“We are a global company first,” Moronu said, “and have a mission to serve people everywhere in the world. So, we’ve designed our aircraft to fly safely across various operating environments and differing regulatory requirements. With safety designed into everything we do, we’ve found that regardless of regulatory environments, our solutions are well received in the places we operate.”

“This is a very exciting year,” Wyrobek concluded. “Congress pushed the industry to find ways to get beyond visual line of sight to scale. With this recent approval that we have, and with the crawl, walk, run process, I’m over-the-moon excited. This is a big inflection point for much of the world’s airspace.”