Blueye team members inspect a hydropower facility for Statkraft, Europe’s largest generator of renewable energy.

Hydropower is the most widely-used renewable energy source, representing about 17 percent of global electricity production. In the U.S., more electricity is generated by hydroelectric facilities and dams than wind, solar and geothermal power combined.

Many of these facilities rank among the oldest power plants, however, with the average U.S. installation in operation for 64 years. As these aging structures reach the end of their design lives, the need to identify repairs for upgrades becomes increasingly critical. The pressure is on to keep the power on, not just for today’s energy needs, but for the needs of the future.

Utility owners, asset managers and contractors are increasingly turning for help to unmanned underwater vehicles (UUVs) and remotely operated vehicles (ROVs) equipped with sonar imaging devices, cameras and sensors.

These systems offer a safe, cost-efficient alternative to sending traditional dive teams underwater for emergency or routine inspections—and they’re playing a key role in minimizing downtime, reducing outages and avoiding catastrophic shutdowns.

“ROVs are expanding our capabilities to safely perform inspections on inaccessible features,” said Ryan Hedrick, a hydrologist at the Bureau of Reclamation, which oversees hydroelectric power generation across the U.S. “This saves a great amount of time and gives us the ability to document structures that are difficult to access.”

Drones That Deliver Where Divers Can’t

One advocate for the use of drones in hydropower inspections is Rory Alsberg, senior business development manager at J.F. Brennan Company, a 100-year-old marine construction company based in La Crosse, Wisconsin, that specializes in dam construction and repairs. In addition to a team of 60 ADCI-certified commercial divers, the company relies on UUVs to assist in keeping facilities up and running.

Alsberg is a somewhat unique authority on hydro inspections; his father started North American Hydro in 1978, so he’s had a front row seat to the ways maintenance techniques—and the case for drones—have evolved over the years.

“Manned inspection teams have expanded from two to four-men crews, so that’s double the cost,” Alsberg said. “Also, new dive guidelines for some larger utility companies require ROVs to test water flows and inspect turbines, intake grates and trash racks before a diver even enters the water. Companies like ours always use an ROV first to scout things out and check water conditions.”

In fact, Alsberg admits there are times when an ROV is the first and only option. Going 100 feet or more below the surface, for example, is exceedingly dangerous for traditional manned methods: “In many cases, such as deep water, confined space or unknown conditions, only a drone can safely get the job done.”

The Blueye Pro ROV can be operated via the Blueye app on an iOS or Android device via a user-friendly controller.

Full-Package ROVs

One of the companies leading the way in safe hydroelectric inspection is Deep Trekker, an Ontario, Canada-based developer that specializes in underwater ROVs. Sales manager Cody Warner believes they’re needed now more than ever.

“Right now, if you have an asset—whether it’s a highway or a utility structure—the goal is to extend the life of it,” he said. “If we enter a recession in the next decade, there won’t be much building, so you have to inspect.”

The best way to do that, he says, is remotely. That’s why Deep Trekker launched REVOLUTION NAV in August. This full-package system includes an expeditionary ROV with improved navigation and current-fighting capabilities. It’s equipped with Bridge software that combines a Doppler velocity log and USBL positioning, as well as optimized sensor data that provides a Google map display with waypoints, along with a 260-degree revolving high-definition camera and manipulator, and six thrusters for stabilization.

Despite these robust upgrades, Warner said, it’s ease of use that sets it apart: “You can take the ROV out of the box and it’s up and running in an hour or two. If you’re an owner or contractor of hydro dams, you can be confident in how to use it and know it’s mission ready.”

Unlike the high costs and lead times associated with manned dive teams, the ROV package allows preventative maintenance inspections at any time to extend the life of a dam. “Many of these structures were meant to be replaced by now, so you have to keep a close eye on them,” Warner continued. “ROVs get into tough places for a much lower cost and in a much safer way. They help build a plan for high-priority structures, to determine how to prevent major catastrophes now and what can be left alone for a while.”

The AES Corporation’s AES Tietê team in Brazil collaborated with a local university to develop an ROV system that has replaced manned diving teams in the region.

Benefits Beyond the Drone

Another leading manufacturer is Trondheim, Norway-based Blueye, which develops and builds drones for underwater inspections around the globe.

In January, the company launched the Blueye Pro, an ROV equipped with a camera tilt-function, powerful LED lights, an advanced piloting system, improved camera quality and a depth rating of 1,000 feet. It can be deployed in minutes with minimal training and is operated via the user-friendly Blueye app on an iOS or Android device.

“The ability to remotely assess the condition of hydro structures is incredibly efficient and cost-saving,” Blueye CTO Jonas Follesø said. “The Blueye Pro is small, so it can be easily transported and can inspect inside tight spaces where humans can’t reach. At the same time, it’s also powerful and robust.”

Follesø predicts that as regulatory guidelines require asset owners to become increasingly proactive with inspections, reliance on ROVs’ benefits will only increase.

“The problem with dive teams is they aren’t necessarily the experts, and you only get one shot at capturing data,” he said. “The quality of inspections tends to increase if the customer can inspect things themselves virtually, because they know exactly what to look for.”

That’s why the Blueye Pro is equipped with an HD camera that is streamed live to the controlling Blueye app. The Blueye Dive Buddy App can also connect to the stream from a separate device, enabling multiple stakeholders to view and report findings in real time.

“Blueye was founded to give greater access to drones, and that extends to our software,” Follesø said. “We release updates that enhance our drones over time. Using a standard iOS and Android enables us to take part in the larger mobile app ecosystem.”

During COVID-19, for example, the company released a software update allowing inspections to be streamed via a virtual Microsoft Teams meeting. The feature enables customers to conduct remote inspections from anywhere with the Blueye drone joining as a “participant.”

“This empowers what customers can do during remote inspections, and demonstrates the flexibility of the platform and ability to roll out features quickly,” Follesø said. “It’s an example of utilizing software to provide benefits beyond the drone itself.”

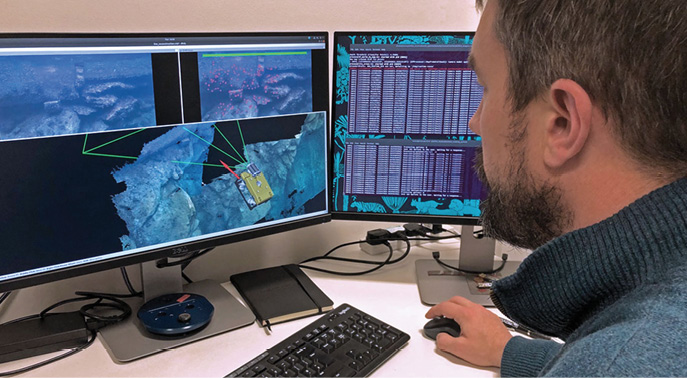

Rovco’s R&D Autonomy Software allows ROV inspections to be supervised in real time from anywhere in the world.

Advancing Autonomy

Also working to take underwater inspections to greater depths is Bristol, England-based subsea technology company Rovco. Its use focuses on developing autonomous systems to improve safety in hazardous, extreme subsea environments such as hydroelectric dams and windfarm monopiles.

“Safe and efficient construction, operation and decommissioning of subsea assets are critically important to energy production,” said Rovco CEO and founder Brian Allen. “This is particularly true for hydroelectric facilities where cost efficiencies are necessary to deliver clean power that is cost-competitive with other low-carbon systems and at an affordable scale.”

Rovco recently secured Innovate UK funding to develop a cutting-edge 3D visualization system, and through the development of AI and path planning algorithms the company is demonstrating the ability to navigate the subsea fully autonomously and perform underwater inspections that can be supervised from anywhere in the world.

Trials are being conducted at the facilities of Offshore Renewable Energy Catapult, the UK’s leading technology innovation and research center for offshore wind, wave and tidal energy. According to Allen, this testing is vital to creating small, capable, intelligent autonomous vehicles that allow more efficient surveys to help get people out of harm’s way.

“Autonomous robotics and intelligent data systems are poised to change how the world works,” he said. “It’s been needed for years, but this tidal wave of change is building up rapidly now, and our industry is about to be accelerated into the future.”

When divers cannot be safely dispatched, the U.S. Bureau of Reclamation deploys a VideoRay Pro 4 ROV with sonar to inspect the structural integrity of dams.

Global Inspections at Scale

ROV developers and subsea technology companies are only a piece of the energy puzzle—energy providers themselves play a critical role. In an effort to improve safety and enable more efficient inspection services, The AES Corporation, headquartered in Arlington, Virginia, has been pioneering a global incorporation of unmanned systems.

Among its 150 drone use cases across seven applications, the AES Tietê team in Brazil is perhaps the company’s most mature business in terms of integrating unmanned systems for hydropower. With nine hydroelectric plants, two wind complexes and two solar complexes, AES Tietê is one of the largest power generation companies in the country.

When sending divers for inspections became too hazardous and costly the team collaborated with UNESP—São Paulo State University to design an ROV equipped with Teledyne Blueview imaging sonar before transforming the research project into a full-scale AES maintenance program, team hydrologist engineer Daniel Sperandelli said.

“In 2018, we avoided more than 1,080 risky job diving hours by using these ROVs,” Sperandelli said. “We also avoided the costs of a dive team and the anticipated two weeks advance notice generally needed due to the risk of the job. If the power plant calls us today, tomorrow morning our team can be there to inspect and solve the problem quickly.”

In addition to the first and second-generation ROVs developed with the local university, the AES Tietê team relies on a Teledyne Oceanscience Q-Boat 1800, a remotely operated hydrographic survey vessel, to obtain bathometry data, and aerial drones such as the DJI Phantom 3 to visually inspect the hydropower dams. These efforts have earned them global recognition and multiple awards, such as an AUVSI XCELLENCE Award for operations and safety improvements.

Deep Trekker’s rugged REVOLUTION ROV provides advanced stability for underwater inspections.

Assel Ayapova, AES’ global drone program manager, leads the company’s efforts to adopt drones at scale for energy inspections. Now four years in, she said the program is entering its next phase—the digital transformation stage of software data and analytics—which will continue to push that adoption to the next level.

Avapova’s quick to point out the critical role drones with play moving forward.

“This is an important time for energy companies to recognize and understand the benefits of these unmanned systems, and how they can safely, affordably and sustainably contribute to the world’s increasing energy needs of tomorrow.”