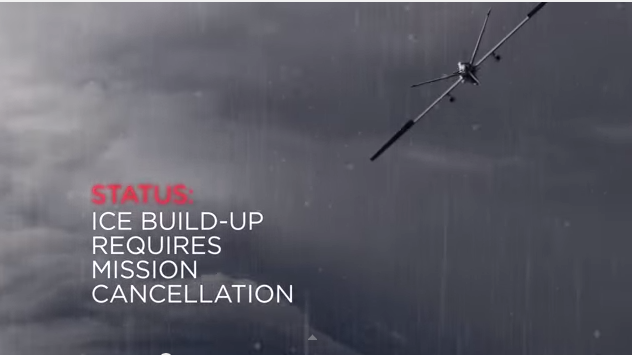

Battelle’s HeatCoat anti-icing technology designed for UAVs demonstrated its ability to perform in-flight anti-icing and de-icing functions during recent wind tunnel testing.

During four days of demonstration and testing, the HeatCoat technology was integrated with representative wing and engine inlet test articles, according to a news release, and then placed in an aero-icing tunnel developed by an aircraft manufacturer.

The chamber is designed to generate the type of icing conditions a UAV could encounter while in-flight. Temperatures dipped as low as -22 degrees Fahrenheit, with air speeds reaching up to 182 Knots. The final results showcased HeatCoat’s ability to successfully perform anti-icing and de-icing functions, according to the release.

How does it work? HeatCoat uses a carbon nanotube coating that is sprayed onto an aircraft surface, much like paint, according to the release. This creates a heated area when power is applied. A controller monitors the heater performance, and only applies the power levels necessary for flight conditions.

This method reportedly can operate on less power, and is lighter than traditional ice protection systems. It has no moving parts and can be retrofitted.

“Battelle has made a long term investment in this technology because we think it is so promising,” said Ron Gorenflo, HeatCoat Systems Product Manager, according to the release. “Our recent tests validated improvements we’ve made and prove that we are ready to go from a Technology Readiness Level (TRL) 6 on to a TRL 7 once we identify a key partner to help complete the next step of this process.”

This de-icing product is said to be well suited for UAVs and their limited payload and power capabilities, but can be used on other aircraft as well.

For more information visit battelle.org or watch this video: