Ilias Tagkopoulos, University of California, Davis

Nitin Nitin, University of California, Davis

The world’s food system is ripe for disruption in an unprecedented way. There are many challenges that we are facing both domestically and worldwide. According to the EPA, about a third of the food supply is lost, accounting for 15% of municipal solid waste and 2% of our energy use. Pesticide and herbicide use has increased more than 10% over the past 5 years while not everyone has access to high-quality food they can afford—which is partially responsible for 40% of U.S. adults and 18% of our teenagers being obese, while one in eight families in America are hungry.

Many of these challenges are caused by inefficiencies in the food processing and distribution supply chain, which is a vital value-added step in our food system. The pieces of the puzzle are all there: ubiquitous sensors and devices that generate data with unprecedented volume, velocity and veracity; mature computational methods to make use of them; connected markets that can take advantage of these innovations at a global scale; and a need to transform antiquated, obsolete components of the current system, whether because of consumer demand for personalization and empowerment, or the need for global food safety and sustainability. Millions are spent every year in both the private and public sector to bring forth innovative solutions in capturing market preference, food safety, food security, provenance and traceability, all the while creating superior products that taste good, are good for your health and don’t break the bank.

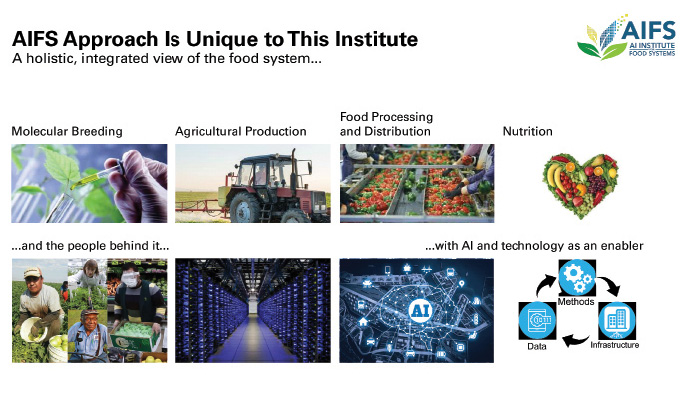

Recently, a strategic initiative by the National Science Foundation (NSF) and the U.S. Department of Agriculture (USDA) has led to the birth of the USDA/NSF AI Institute for Next Generation Food Systems (AIFS). AIFS is a $20 million collaboration between UC Davis, UC Berkeley, UC Agricultural and Natural Resources, University of Illinois and Cornell University, with the mission to “develop and leverage transformative AI for the ethical production and distribution of safe, sustainable, nutritious food with fewer resources.” With more than 50 faculty participating, AIFS aspires to use AI as the connective tissue that brings together the different segments of the food system, from molecular breeding and agricultural production to food processing and consumer nutrition.

FOOD SAFETY, AI AND MORE

Food safety risks are the leading causes of food recalls in the industry and a significant impact on health, social and economic aspects of our society. These risks range across diverse categories of food products, including dairy, meat, fresh produce and raw dry powders, while their main cause is contamination of food products with microbial pathogens in the harvesting and processing environments. The sources of these contaminations are diverse and often are not detected a priori with conventional testing. That is due to a lack of comprehensive sampling techniques and services that can provide accurate results in an inexpensive and timely manner.

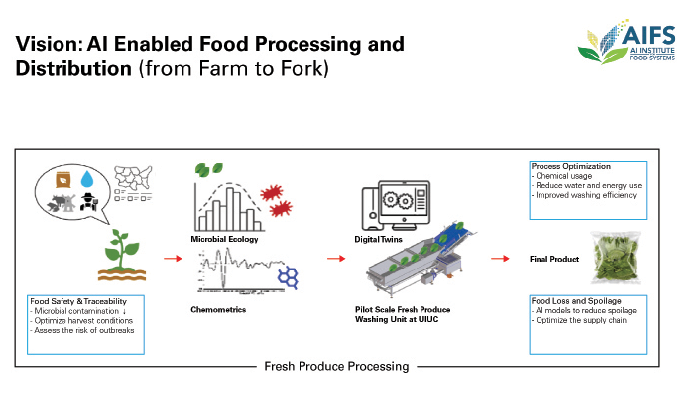

This is where the trifecta of next-generation sequencing, artificial intelligence and cyber-physical systems can have a multiplier effect in keeping our food supply safe. Traditional 16s gene sequencing and, more recently, metagenomics sequencing, together with rapid identification of the microbial consortia in a sample, can quickly detect the presence of dangerous pathogens, such as Listeria monocytogenes.

AI-driven algorithms can be trained to assess the outbreak risk level by calculating the relative abundances of the various microbes in factories and food processing facilities. This can eventually lead to an always-on alert and recommendation system that can predict potential contamination and recommend corrective actions to reduce the risk of outbreaks and the cost of product recalls.

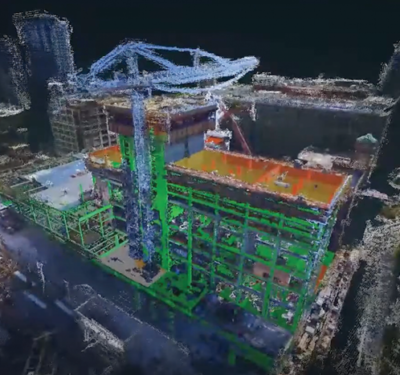

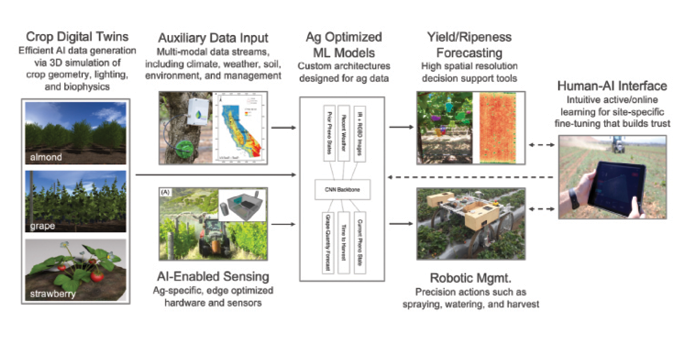

Furthermore, digital twins can serve as a clone digital replica of the factories, distribution centers and other areas where contamination is possible, providing a platform to evaluate hypotheses, optimize solutions and better understand system dynamics while constantly integrating feedback from the physical system.

Eventually, AI-driven systems that have the flexibility to integrate the existing food microbial ecology, chemometric and physical data sets for a comprehensive assessment of food safety risks can revolutionize food safety and create a safer food system, from farm to fork.

The AI Institute for Food Systems’ Value Chain

AI enrichment through the food supply chain.

AI MEETS DIGITAL TWINS

Many food processing operations such as sterilization of food products, drying and baking require significant energy and water resources. In addition, sanitation operations required for the hygiene of the processing equipment use a significant amount of energy, water and chemical resources. With emerging climate challenges, there is a marked need to develop solutions to address these challenges.

Many of these efforts have focused on conventional engineering approaches such as waste heat recovery and reuse of spent water resources. Digital twins can again help by becoming an inexpensive testbed, as they can provide a digital replica of a processing operation and enable real-time analysis of water, energy and chemical usage in a facility. With cloud computing and scientific computation techniques, practitioners can run millions of simulations in minutes to identify the parameters that lead to the best possible resource use. Adaptive techniques such as active learning can be used to incorporate feedback from the physical system and improve the system’s performance in maximizing efficiency.

In addition to opportunities for process optimization, these combinations of AI and digital twin technologies can aid in process validation and verification. Process validation and verification are required by regulatory organizations to ensure the safety of food products. Validation and verification processes in the food industry often require inoculation of food with a surrogate microbe to target pathogens and its testing following processing. These are resource- and time-intensive processes. AI-enabled digital twin technologies and data analytics can provide real-time validation and verification of processing operations.

In addition, significant early-stage efforts have been made to AI solutions for quality evaluation of input and output streams from food processing operations. The development of AI-guided sorting of fresh produce, such as blueberries, has shown significant improvement in efficiency and reducing labor-intensive practices in the industry. There are opportunities to advance vision and sensor-guided sorting of input and output streams of diversity of food products to improve the quality of the products and reduce food waste. Despite these early successes, there are many other areas in the quality control of food processing operations that are still managed based on empirical human decision-making processes: e.g. consistency of pastes and juices derived from agricultural commodities, such as apples and tomatoes, which are largely managed based on human judgment.

AI can revolutionize food safety and create a safer food system.

MAXIMIZING NUTRITIONAL AND CONSUMER VALUE

Producing and making available food that is good for our health, wallet and taste palate is the Holy Grail of any food and nutrition company. AI can play a significant role here, both unlocking the mysteries of chemical composition of food and creating new functional products. A significant blocker for any AI chef is the lack of the molecular atlas of food, knowing at high resolution what is in each ingredient beyond the protein, fat and carbohydrate content that we have been used to for generations. Not all proteins or carbs have been born equal when it comes to what they do to our body and mind. Even when we know the compounds—may they be small molecules, peptides, glycans or anything else—that confer benefits and help us transition to a healthier state, each of us has different genetics and gut microbiota, which in turn lead to strikingly different responses.

The complexity of the food-host interaction is both fascinating and daunting, and this is exactly the space where visionary initiatives can have a transformative impact in our way of life. AI-driven product formulations that are tailored for the individual needs of target groups, and that are specific enough based on co-morbidities, age or biomarkers, can be a paradigm shift that will epitomize the Hippocratic “Let food be thy medicine.” Optimal food processing is an equally important and complementary task, as the texture, nutritional value and function of the final product depends on it, with many of those beneficial compounds being lost in the process.

LOOKING AHEAD

In the next 5 years, we will witness a paradigm shift in how we perceive, produce and consume food. There are already significant efforts to adopt and adapt the latest in sensor technology and AI in various aspects of the food system, while a number of initiatives with significant funding have been focused on mapping the molecular composition of various food ingredients. The AI community has made major advances in creating explainable and interpretable AI solutions, with a focus on fairness, trustworthiness and the ability to predict even in areas where there is a scarcity of data. Taken together, we expect an adaptive radiation of solutions and a rich ecosystem of partnerships fueled by unprecedented innovation and a strong desire to bring forth the next generation of food systems for a better tomorrow.

Authors

Dr. Ilias Tagkopoulos is a professor of computer science and the Genome Center at the University of California, Davis, where he leads the Integrative Biology and Predictive Analytics laboratory. He also is the director of the USDA-NIFA/NSF AI Institute of Next-Generation Food Systems (AIFS), a seven-institute collaboration. His work addresses data integration, modeling, design and decision-making under uncertainly, with applications in clinical and nutrition data. He holds a MSc from Columbia and a Ph.D. from Princeton in electrical engineering.

Dr. Nitin Nitin is co-principal investigator and lead of the Food Processing and Distribution Cluster at the Artificial Intelligence Institute for Next Generation Food Systems (AIFS). He is a professor in the departments of food science and technology and biological and agricultural engineering at the University of California, Davis. His research focuses on improving food quality and safety by developing innovative solutions focused on food processing, encapsulation, novel antimicrobials, biosensors and imaging. He holds Ph.D.s in bioengineering and food engineering.